23

REVERSE CYCLE DEFROST

General Information

Master-Bilt’s patented (U.S. patent no. 7,073,344) reverse cycle defrost is a standard feature on Master

Controller-equipped refrigeration systems. A reverse cycle valve is already factory-installed on the

condensing unit. The valve’s primary function is to reverse the direction of the refrigerant flow during defrost.

When the Master Controller’s demand defrost determines that a defrost is necessary, the reverse cycle valve

is activated and the high temperature refrigerant flow is reversed.

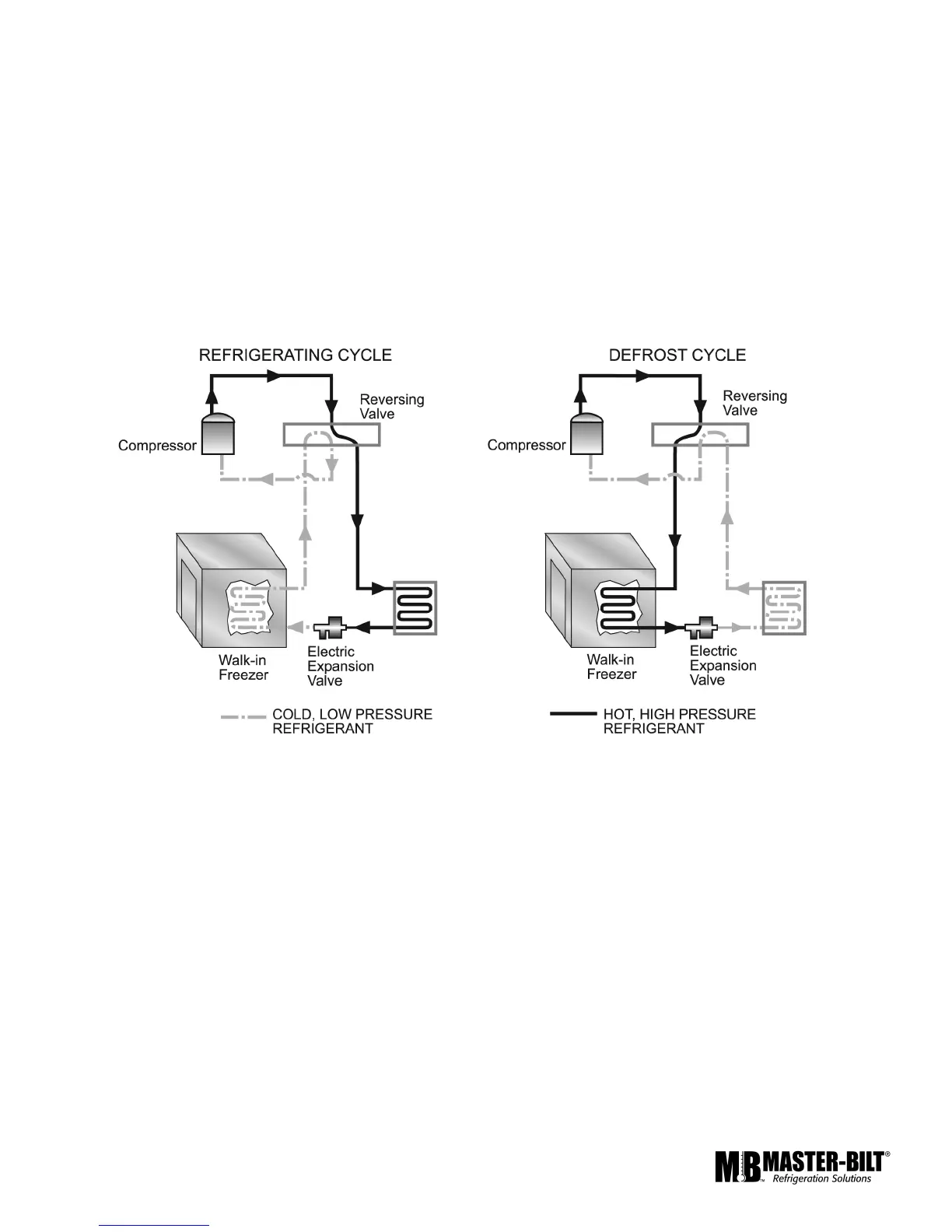

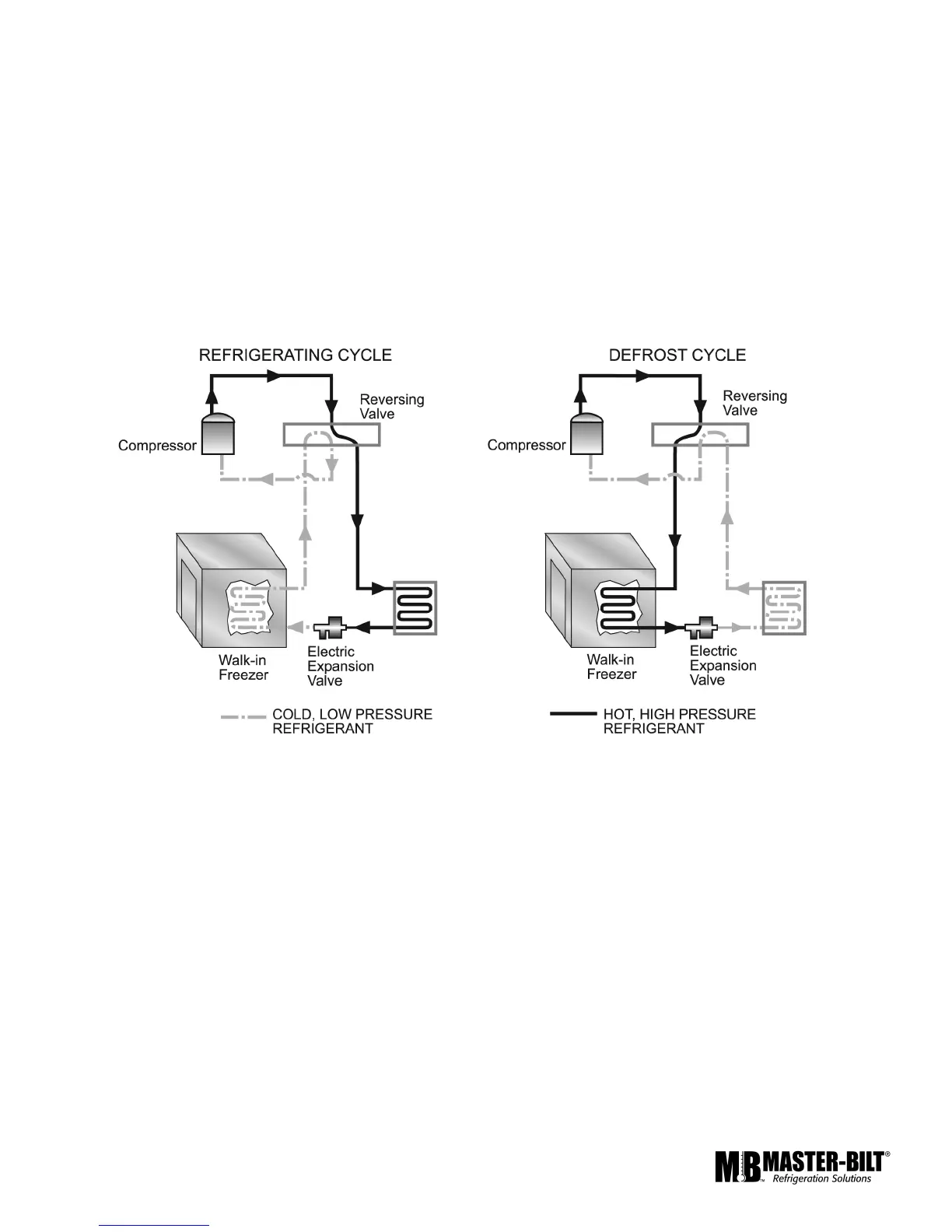

Under the normal refrigeration cycle, the refrigerant flow is the same as traditional refrigeration modes. During

the defrost mode, the refrigerant flow is reversed back through the evaporator coil heating it from the inside-out

along its entire length and completely eliminating frost buildup (see figure 5 below).

Figure 5

Advantages

Reverse cycle technology offers several significant advantages:

• An up to 80% reduction in defrost energy usage. This savings, coupled with that from the demand

defrost feature, dramatically reduces energy consumption.

• Eliminates many mechanical parts

• Reduces cost of evaporator, installation and wiring

• Reduces defrost time

• No significant increase in freezer room temperature

• No noticeable increase in product temperature

Factory-Installed Parts

A 4-way reversing valve, operating at 24 VAC, is installed in a reverse cycle defrost unit. A transformer is also

installed in the master evaporator to supply 24VAC to the 4-way reversing valve.

Loading...

Loading...