29

MIG 140 INVERTER WELDER 058-9305-6

MIG welding operation

Holding the welding torch (MIG gun)

• Before starting the welding operation, try holding the torch in different positions until you

identify a suitable position.

Positioning the torch on the work piece

There are two angles of the torch nozzle in relation to the work piece that must be considered when

welding.

DANGER!

Potential hazard that will result in serious injury or loss of life.

• Consult a qualified electrician for proper installation of the electrical outlet.

• Make sure the welder is properly grounded. If not, contact a qualified

electrician for all electrical connections. Failure to comply will result in electric

shock.

• Do not cut off the grounding prong or alter the welder’s power plug in any way

and do not use any adapters between the welder’s power cord and the

electrical outlet.

• Make sure the power switch is turned OFF before connecting the power cord to

a properly grounded 120 V AC, 60Hz, single phase,16 A power source.

Angle A (60 degrees) Angle B (30-45 degrees)

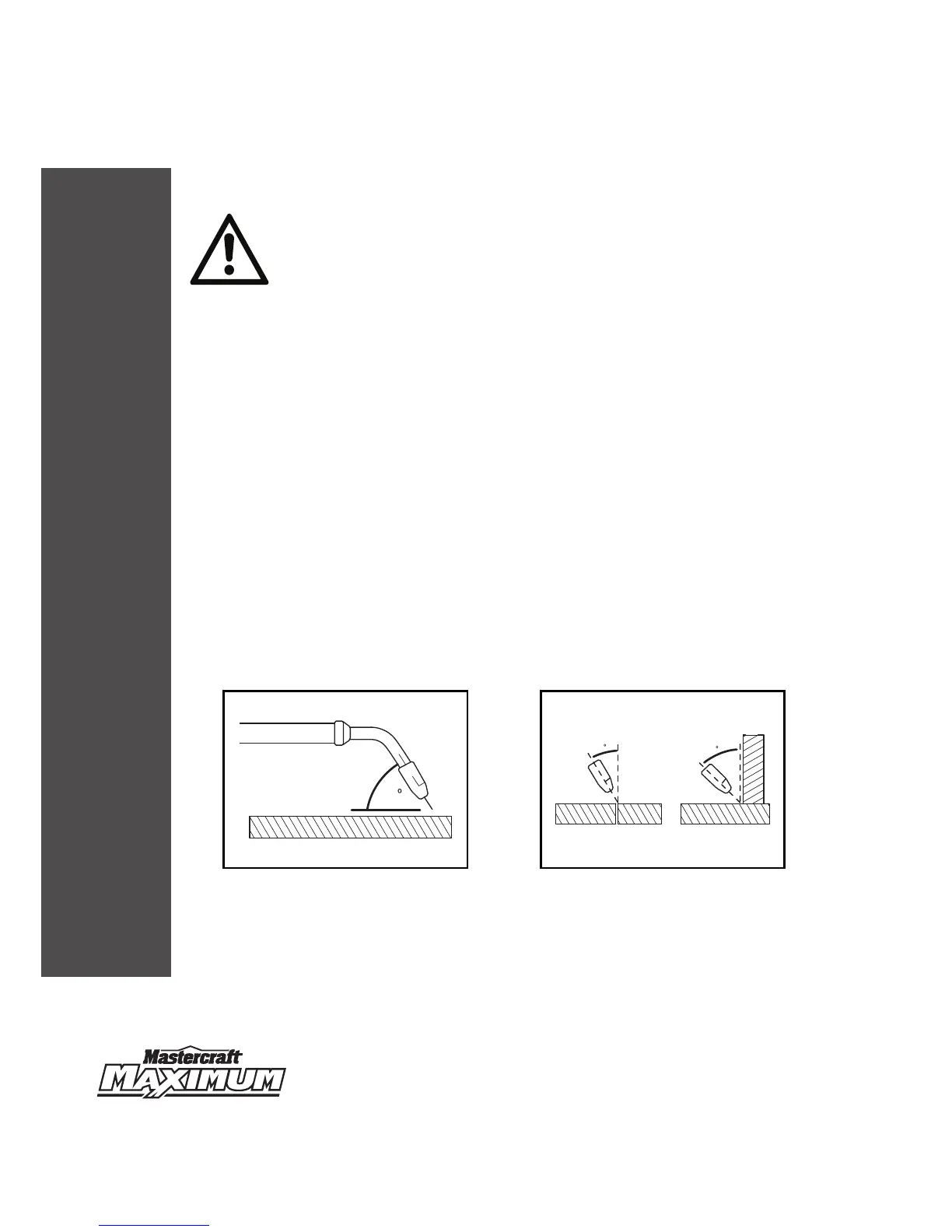

• Angle A is the angle between the nozzle

and the work piece and can be varied, but

in most cases the optimum angle will be

60 degrees (the point at which the torch

handle is parallel to the work piece). If

angle A is increased, penetration will

increase, and if it is decreased penetration

will decrease

(fig V)

.

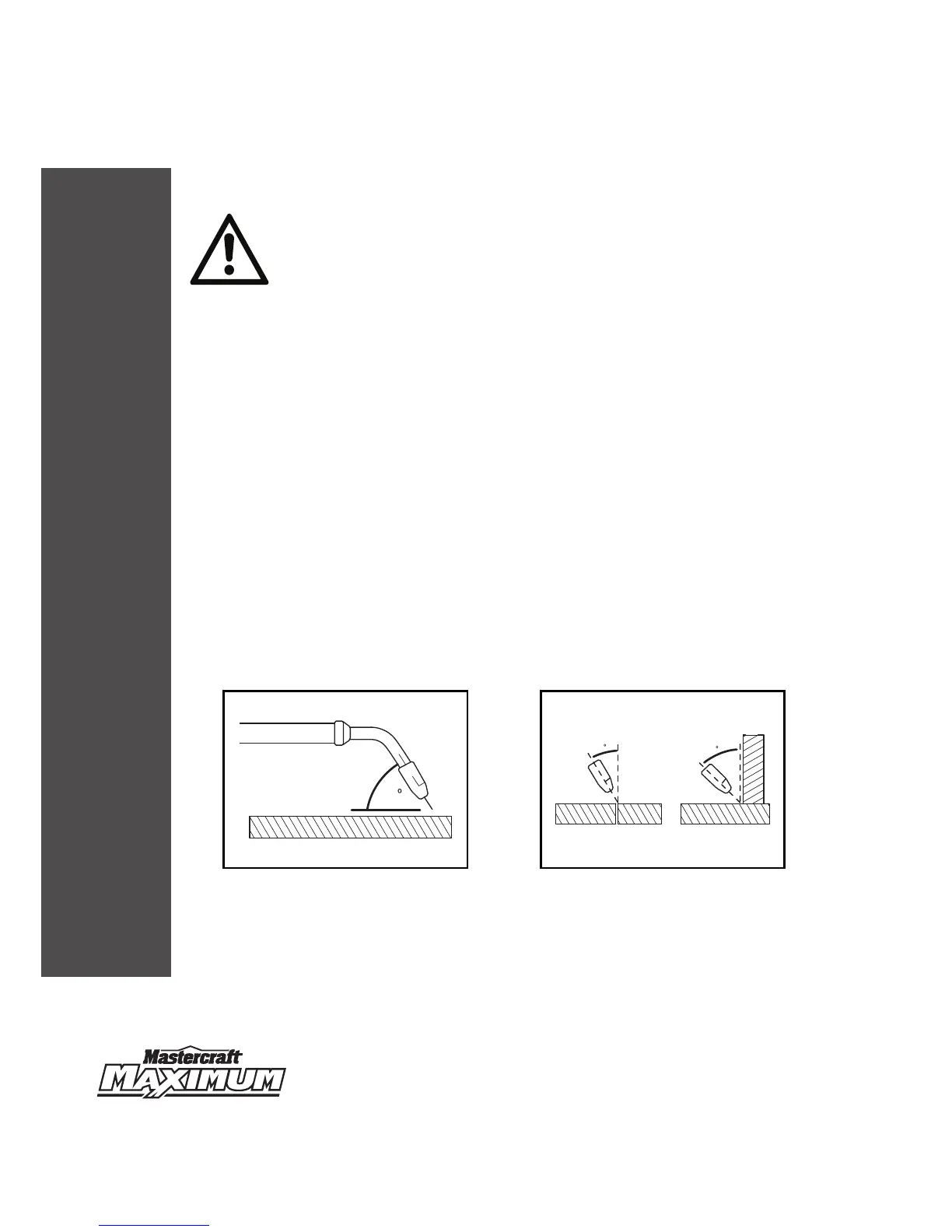

• Angle B is the angle between the

perpendicular of the work piece and the

nozzle and can be varied to improve the

visibility of the arc in relation to the weld

puddle and to direct the force of the arc

(fig W)

.

Loading...

Loading...