8 EN / MOBILE WHISPER 6/12-6/8/10/12/16 ULTRA / November 2004

INSTALLATION

be mounted on rubber mountings. When the clicking

noises of the pump are not acceptable an other

noiseless pump is available as an option.

3 FUEL PIPES

When the tank is above the generating set we recom-

mend to end the return line on the top of the tank.

When the return is on the top - in case of a leakage -

the return line cannot overflow because of siphoning.

One will only need a fuel cock in the fuel supply line.

Both supply and return fuel pipe lines should be

appropriate material and 8 mm outer diameter tubing.

The quality of the tubing of fuel pipes could be sub-

mitted to local regulations depending on the applica-

tion of the vehicle.

The fuel pipes can be plumbed to the flexible hoses

which are on the generating set and have a connec-

tion to fit to 8 mm pipe. The fuel lines Mastervolt

supplies are according to ISO 7840 A2.

It is important to avoid bends in the pipes, as they

could trap air bubbles. The return pipe should never

be connected to the suction pipe. The return line

should be of 8 mm diameter and go straight back via

the top to the bottom of the tank. When the return is

too narrow, has too many bents and goes back to the

bottom of the fuel tank, the back-pressure could be to

high. This results in irregular running of the engine.

When the engine runs irregular, one can check if

back-pressure is the problem by disconnecting the

return line just outside the canopy and draining it in a

canister. When the engine runs smooth now, the

return piping has to be changed. It could also help to

install a second (electrical 12V) fuel lift pump.

4 FUEL FILTERS

A fine fuel filter is installed which requires maintenan-

ce. Mastervolt advises to install an extra fuel filter/

water fuel separator near the fuel tank.

Before starting your generating set for the first time

follow the fuel system bleeding procedure in the users

manual.

2.4.2 RADIATOR COOLING

1 General instructions

The radiators can be mounted below the floor, in the side

or on the roof of the vehicle.

Wherever the radiators are mounted the well functioning

of the system depends on the well circulation of the

coolant.

Roof mounted radiators bring the most risk for circulation

problems, because air trapped in the radiators or a low

level of the coolant, will immediately affect the cooling

capacity of the radiators.

It is recommended to keep the radiators as close as

possible to the unit. The piping should be fitted as direct

as possible.

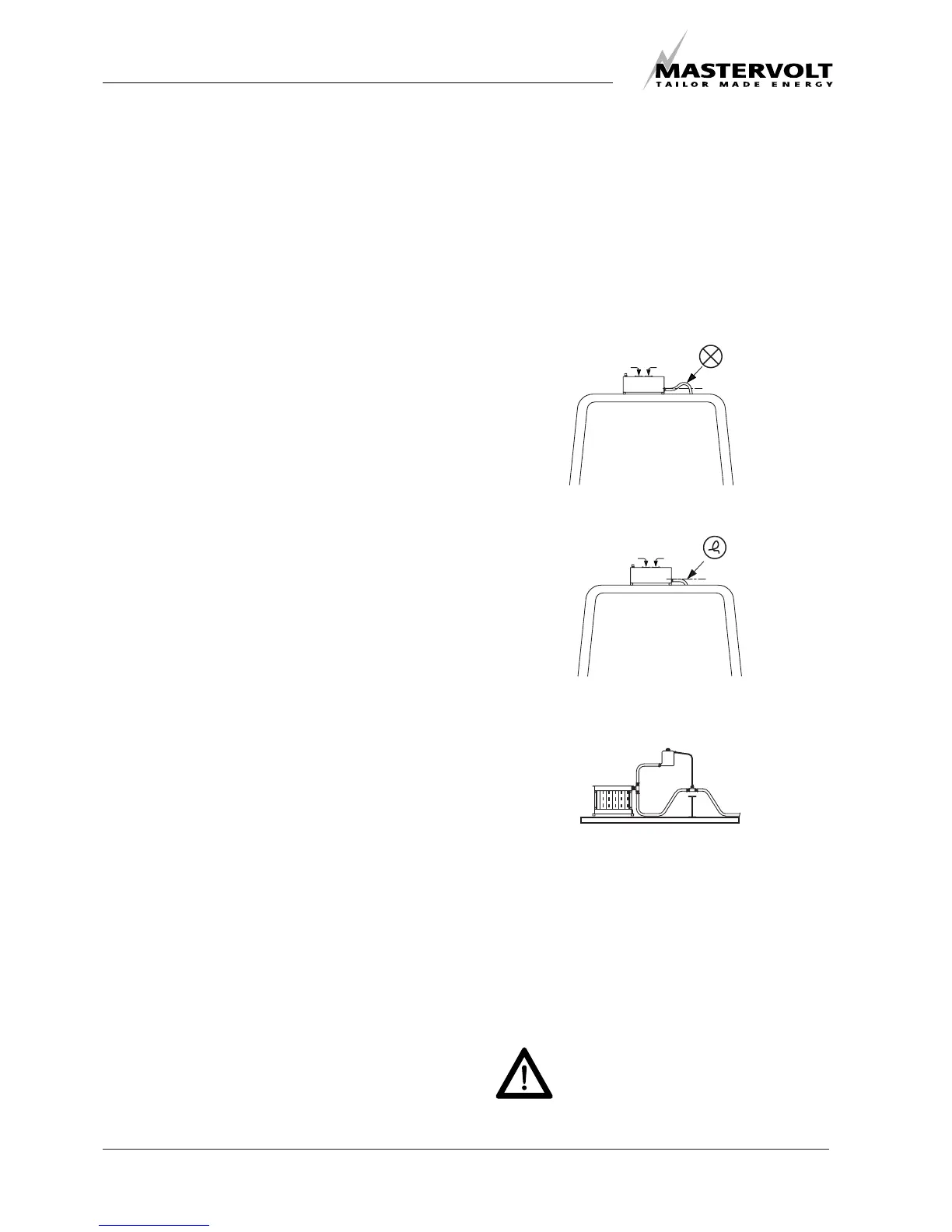

When the radiators are above the engine, the piping should

be fitted below the top of the radiators! (refer to figure 12).

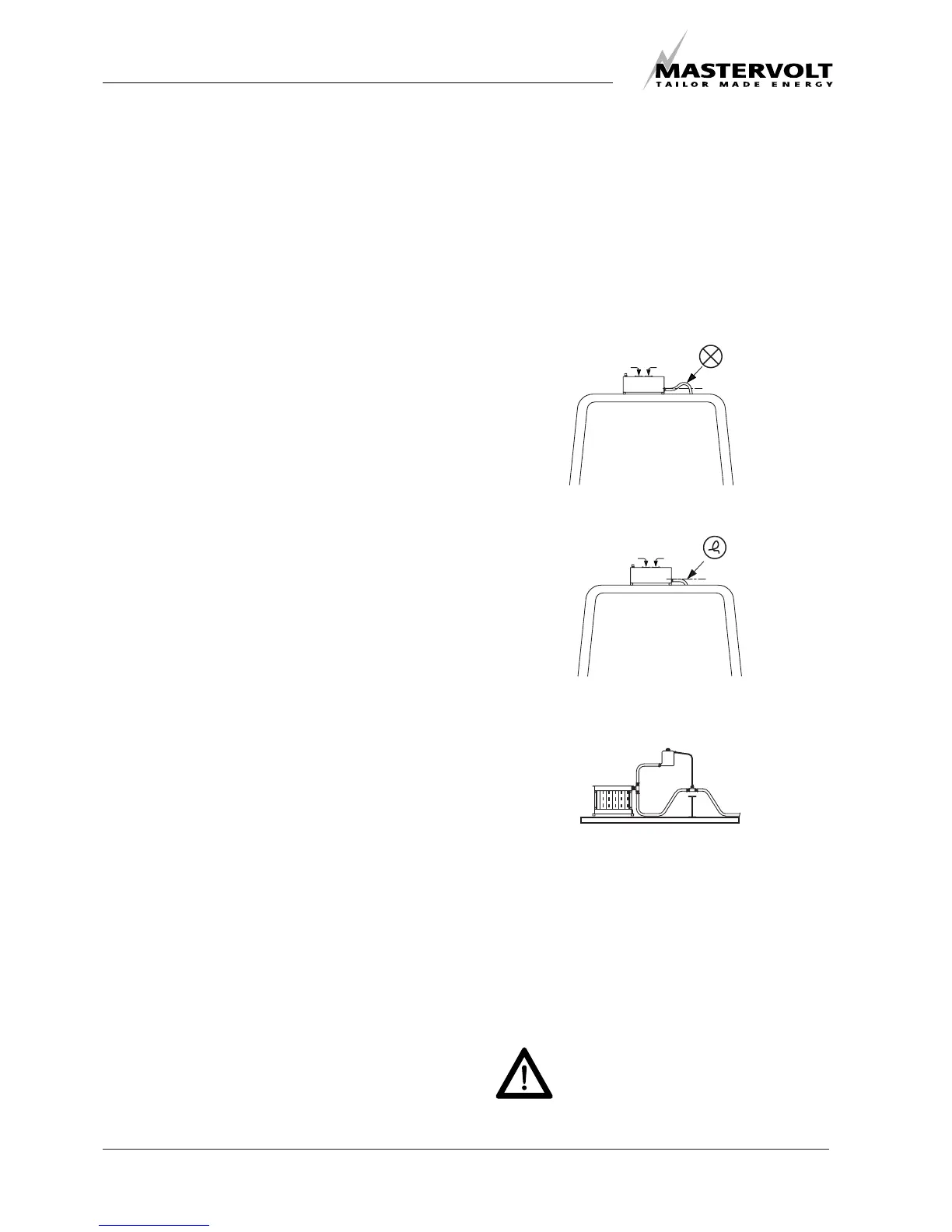

Bents in the piping, that can trap air bubbles, should be

avoided or ventilated (refer to figure 13).

Special attention should be paid to the ventilation of the

systems. Each installation system is standard supplied

with an expansion tank for the coolant, which is also

used to release air bubbles and makes it possible to add

coolant into the system in an easy way. This expansion

tank should be at the highest point of the system and

mounted as high as possible.

Most cooling problems originate from air

traps blocking the circulation of the engine

coolant.

No bent of piping above the radiator

Fig.12. Remove the air trap

Fig.13. Ventilating an air trap

Loading...

Loading...