H-Series User Manual Rev2021A 2

Your Max Flow Meter has been congured at the factory to be used out of the box based on your submitted application

data. Plumb it, wire it, and use it. The following section will provide instructions on how to properly plumb your Max Flow

Meter in the liquid lines of your application.

Use the “IN” port or follow the ow direction arrow markings for the primary ow direction. Install the meter on the

discharge side of the pump whenever possible. Excessive vibration at the meter should be avoided.

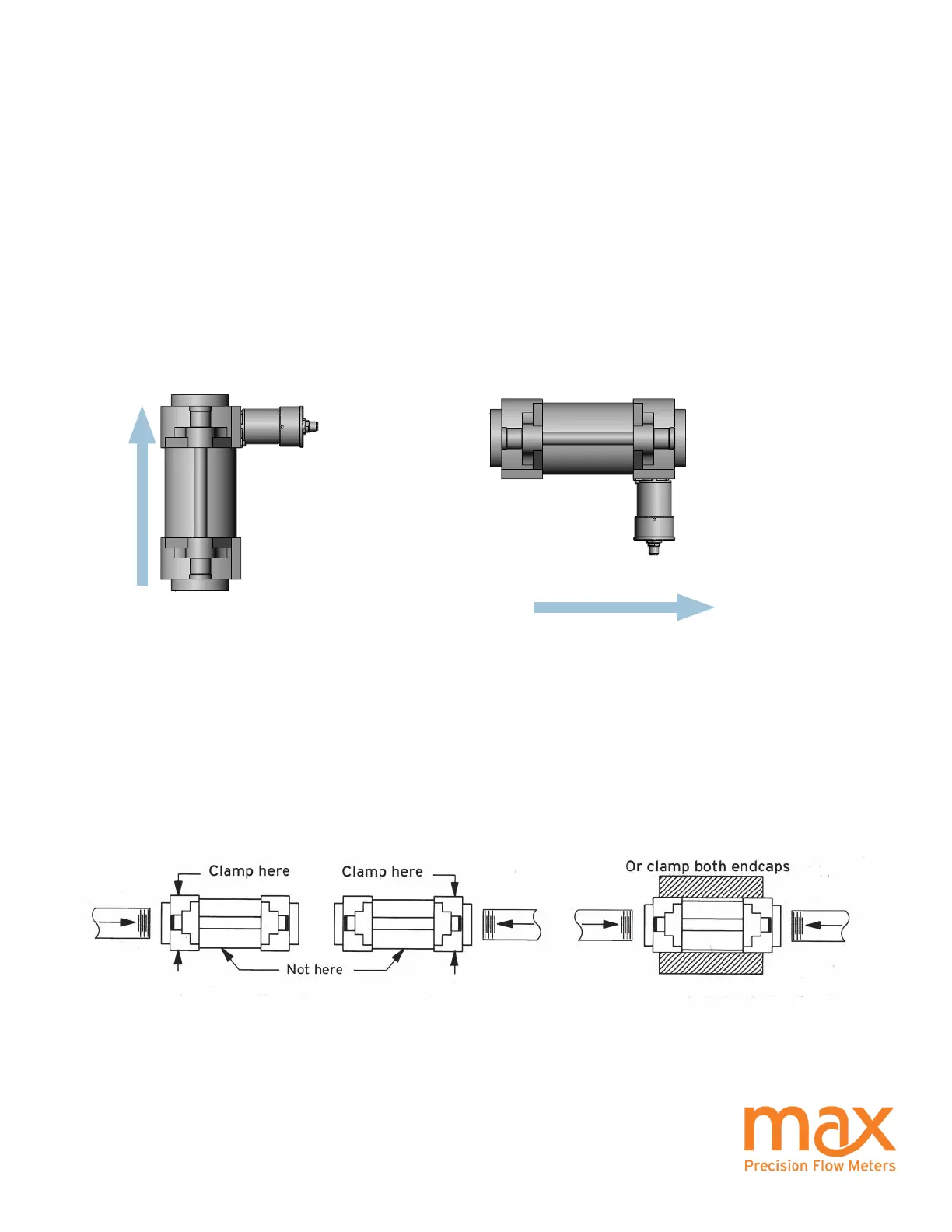

Orientation: Preferred mounting orientation of the meter depends on meter type. The orientation optimizes air purging

and/or minimizes heat transfer to the electronics. H-Series meters, especially when used with thick uids, should

mount with the transmitter on the side and the plumbing oriented vertical ow up. For lower viscosity uids, horizontal

mounting with the transmitter facing down or to the side is also acceptable. These mounting orientations prevent air in

the system that can cause response delays and errors in measurement.

NPT ttings: Always use pipe sealant or pipe tape to install ttings, and leave the rst thread of pipe exposed. Ensure

the tape or sealant does not accidentally enter the meter. Maximum pressure for NPT ttings is 500 psi.

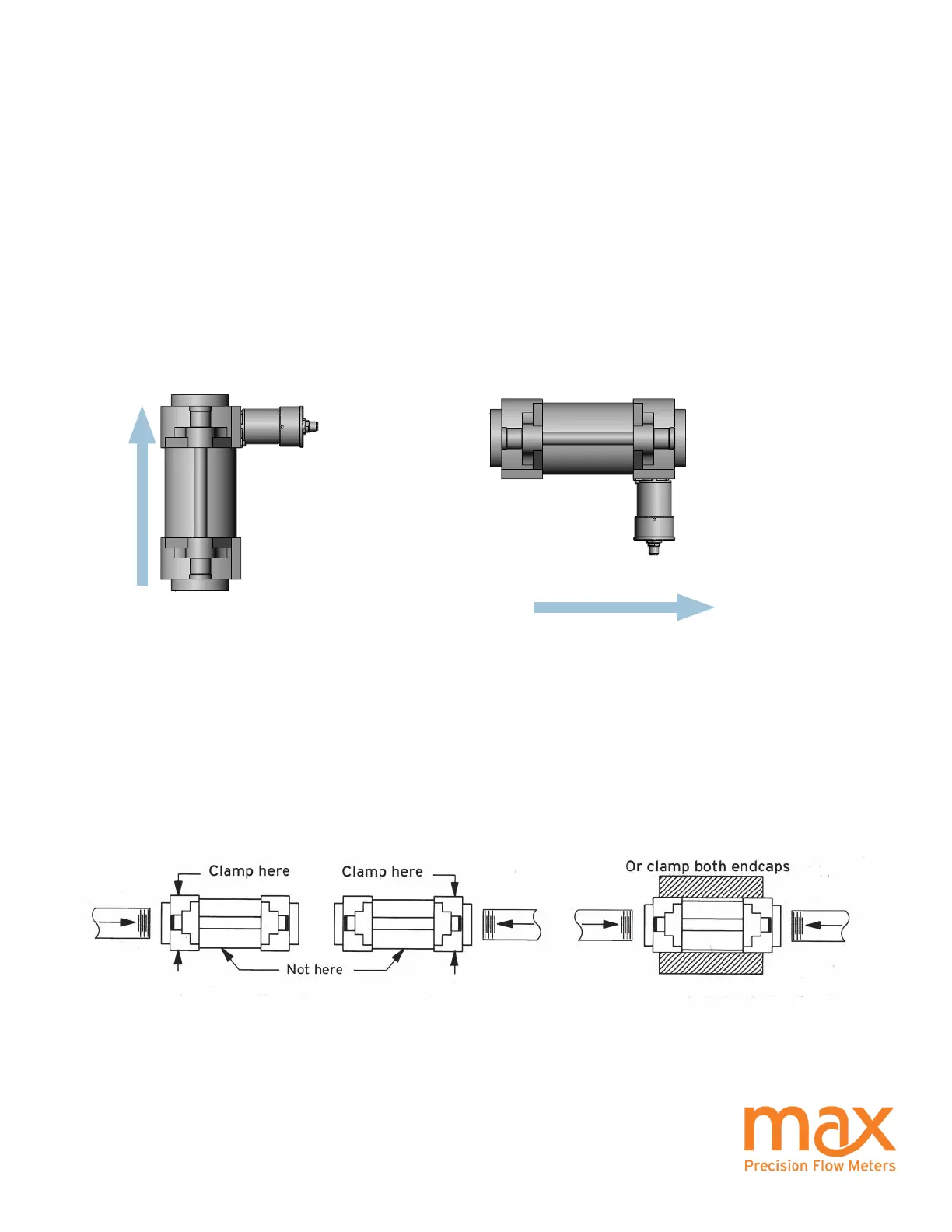

When installing NPT pipe to the ow meter, support or clamp the nearest end cap or both end caps. Do not clamp the

ow meter body. This prevents misalignment of ow meter components when the pipe is installed. Check for proper ow

meter operation by rotating the timing gear through the transmitter mounting hole. It should move freely and without

noise.

Installation - Mechanical

FLOW

H241

FLOW

H241

Loading...

Loading...