H-Series User Manual Rev2021A 4

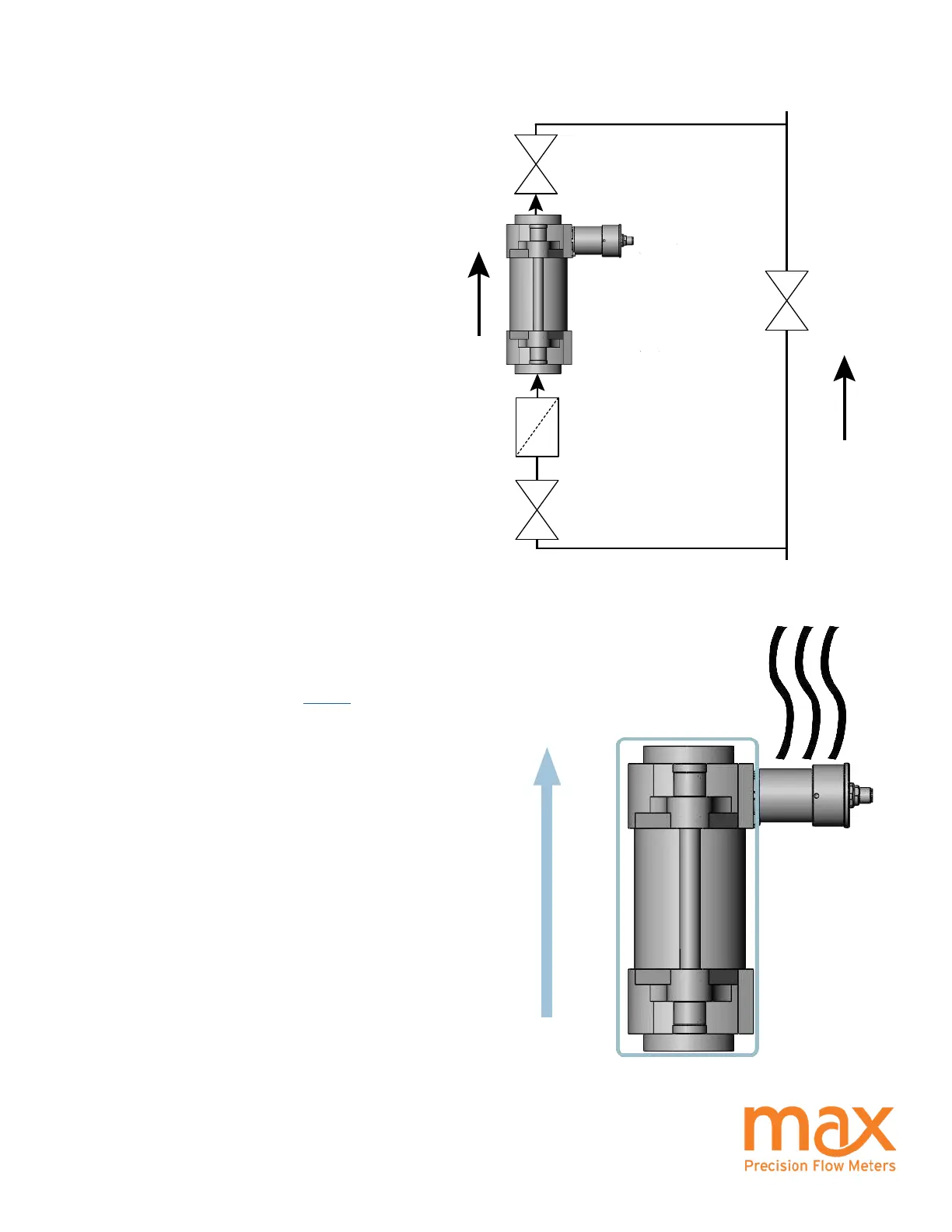

Bypass Valves: Install valves to allow system start-

up, lter replacement, or ow meter removal without

completely shutting the system down and draining the

lines. See diagram.

Failure to use a bypass at start up may lead to ow meter

damage due to debris, overspeeding the meter with air in

the lines, and pressure shock due to initial line surges.

Filtration: A 150 micron lter is recommended on the

inlet for all H-Series ow meters. If measuring bi-

directional ow, a lter should be installed on both sides

of the ow meter. Materials with high viscosity or brous

or non-abrasive particulate matter may need to be run

without lters.

Clean Plumbing: Before installing the ow meter, the

system lines shall be cleaned and free of all debris

or manufacturing particulates. Purging lines with

compressed air or steam are typical cleaning methods.

Do not use compressed air or steam on the Max ow

meter, damage will occur.

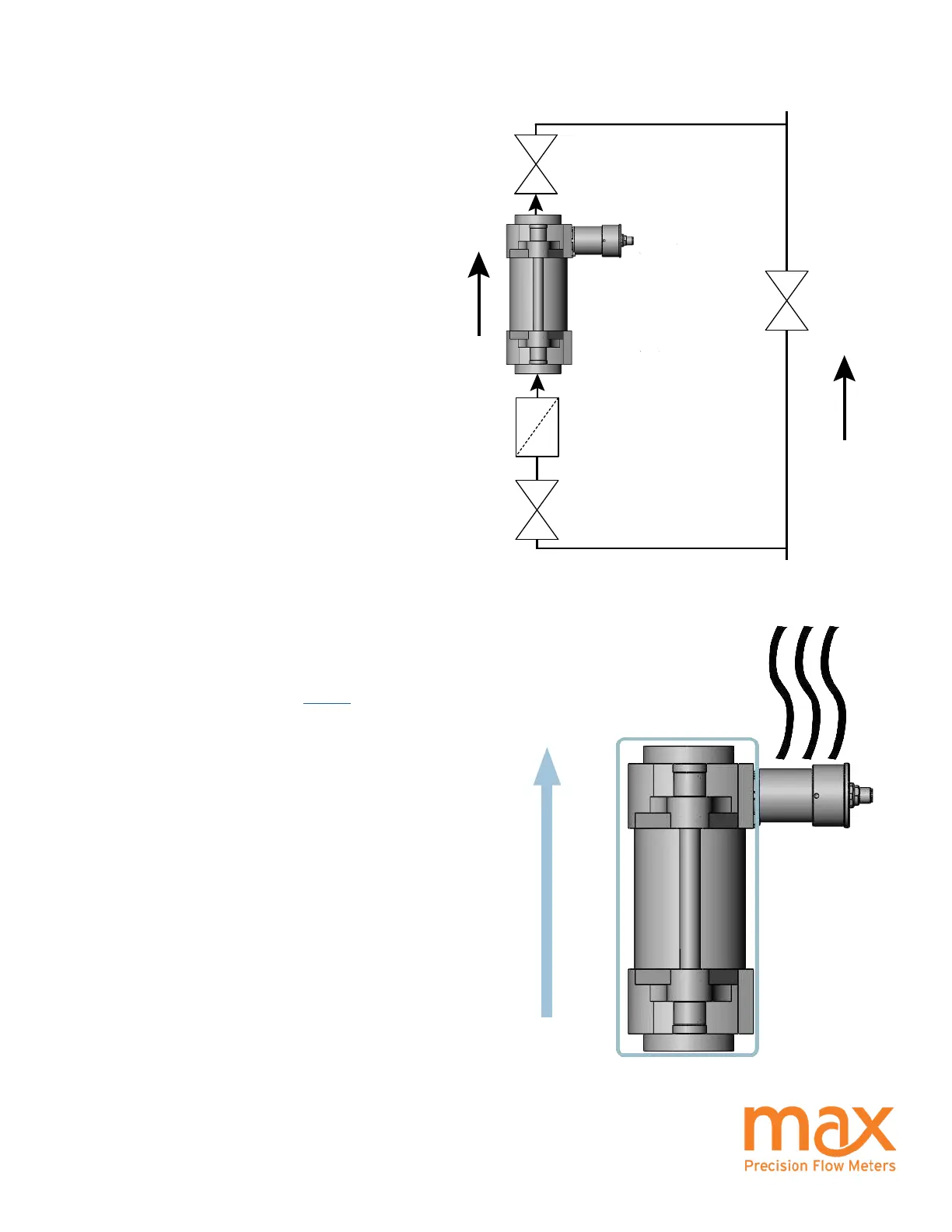

High Temperatures: Orient your meter so the transmitter is to the side

or below to minimize heat transfer by convection from the ow meter

to the transmitter. The transmitter is the most heat sensitive element

in the system. Consult the chart on page 9 for specic limits on uid

and ambient maximum temperatures. When operating in the upper

temperature ranges, always insulate the meter but leave the transmitter

housing exposed so it radiates heat. Optional heat tracing can be

used on the ow meter to keep it at the uid operating temperature.

For substances solid at room temperature, heat tracing may be

required to keep material molten to ow through the meter.

Installation - Mechanical

Valve #2

Valve #1

Valve #3

Bypass

Filter

Flow

Flow

FLOW

INSULATION HERE

RADIATE HEAT HERE

Loading...

Loading...