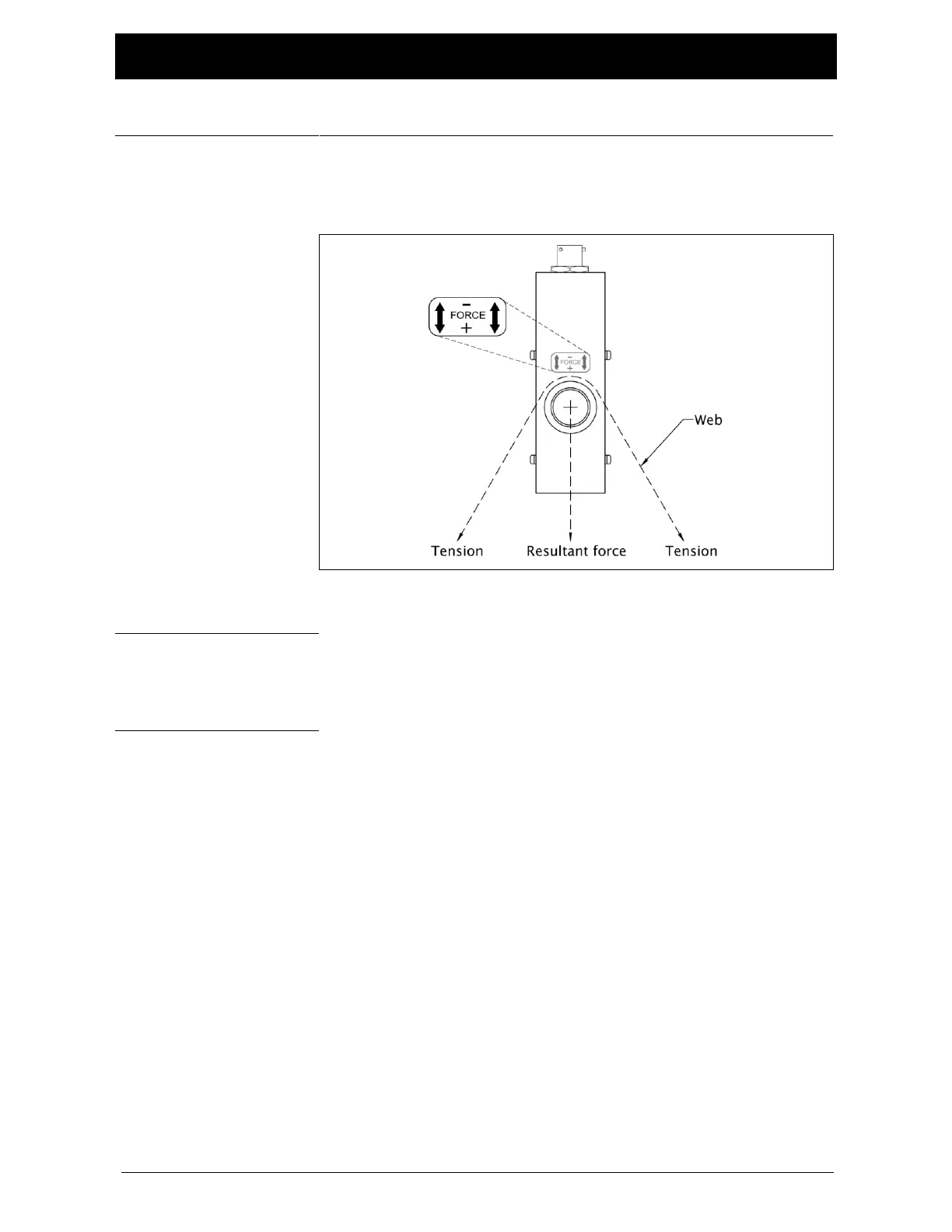

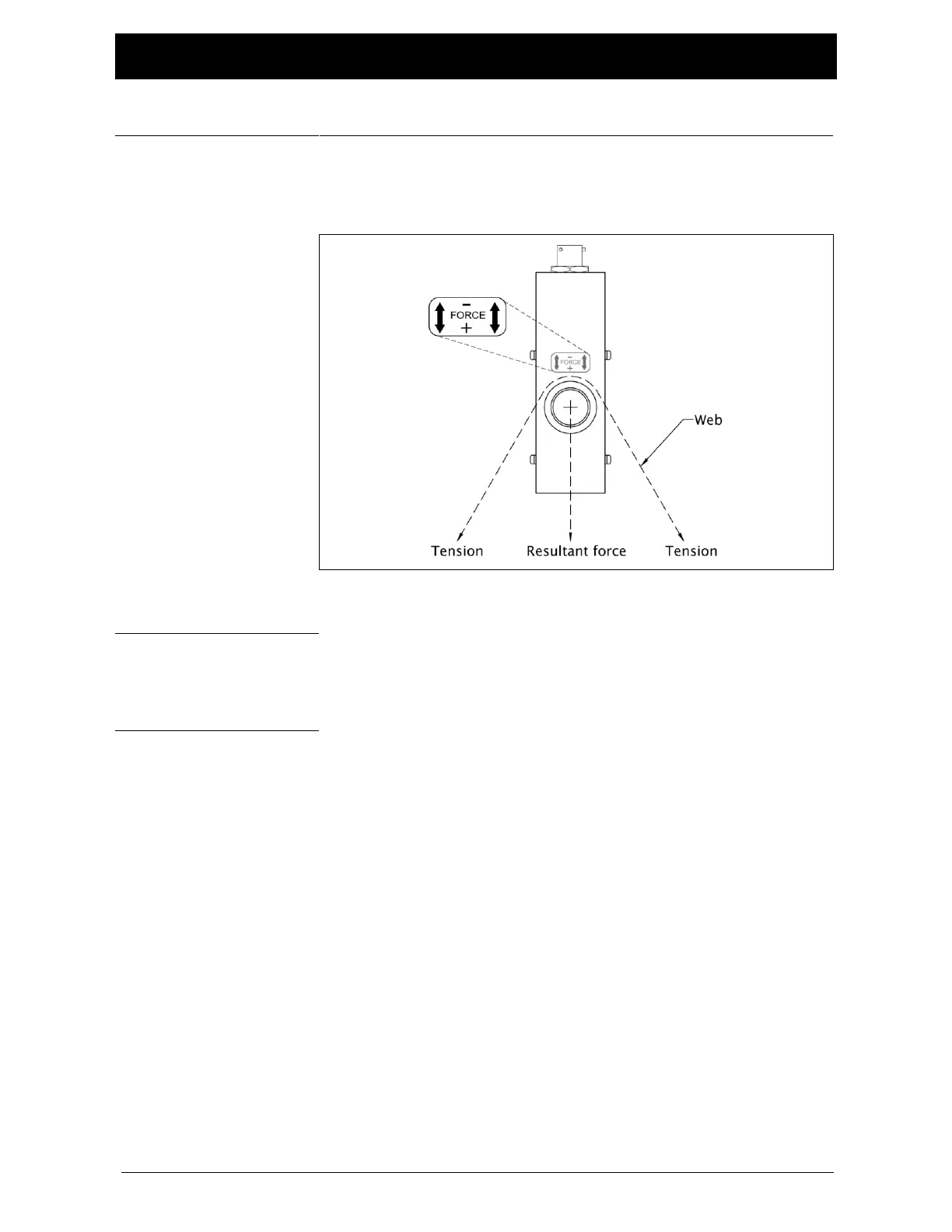

The force direction arrow should also bisect the wrap angle of the

web, and point in the same direction as the resultant tension

force as shown in

Figure 2.

1. Insert the customer’s shaft and roll assembly into the CL

Load Cell as shown in

Figure 1; page 5-1

.

2. Make sure that neither the shaft nor the roll will interfere

with the CL load cell housing or the machine side frame.

For outside frame mount, the minimum clearance hole

diameter in the machine side frame is:

CL1 models 17.5 mm [0.69 inch]

CL 2 models 26.9 mm [1.06 inch]

3. Tighten all four set screws securely against the shaft.

4. Connect the CL load cell to the control with shielded cable.

Loading...

Loading...