12

5.5.5 General rules when operating winch

1 - Always operate the winch control to payout the loadline while extending the boom. This will maintain

clearance between the boom tip and loading hook.

2 - Do not pull load block into boom tip.

3 - Make certain the winch cable is not twisted or kinked and that cable is properly seated on the drum and

in the sheaves.

4 - Before lifting a load, always make certain that three full wraps of rope will remain on the drum at all

times throughout the lift.

5 - When lifting a load approaching the rated winch load, raise the load a few inches and return the con-

trol to neutral to determine if the brake is working properly.

6 - Do not drag loads in any direction with the winch.

7 - Never attempt to lift loads wich are not loose and free, i.e. frozen down material or poles out of ground.

8 - Maintain tension on the loadline at all times to prevent the cable from becoming twisted or improperly

seated on the winch drum or sheaves.

9 - Avoid rough boom lifting and lowering manoeuvres with suspended load, in order not to cause dan-

gerous swingings of the same.

10- Avoid boom extension manoeuvre under load. When moving loa-

ds near to max. rates it is rather advisable to extend the boom

without load in order to reach the vertical line of the same, and

then to proceed with lifting by using the winch.

5.6 WIRE ROPE

5.6.1 General

Wire rope can be the weak link in crane safety. It is subjected to heavy

loads, abrasion, kinking, extreme weather conditions, chemical attack and

other forces which can reduce its reliability. The inspection and care of

wire rope is essential in the effort to provide for safe working conditions.

5.6.2 Wire rope precautions

1 - Avoid the formation of kinks. Kinks will cause severe weakness in

the rope. No corrections are available for kinked rope.

2 - Do not drag wire rope over a non-rotating support such as a non-

functioning sheave. Severe abrasion caused to outer wire strands

will result from friction.

3 - Do not use worn sheaves or flat grooved sheaves. They do not

provide support to the full radius of the rope. Flattening and distor-

tion will result.

4 - Do not use nicked or otherwise broken sheaves. Necks and cracks

in sheaves will cut the wire rope.

5 - Evenly wrap wire rope onto the drum. Uneveness will cause crushing

and/or crimping of the rope.

6 - Select replacement wire rope to match the capacity and use of the

crane. The crane was originally equipped with appropriate wire rope.

7 - Do not expose the rope to corrosive chemicals.

8 - Lubricate the rope frequently to reduce friction and help prevent cor-

rosion.

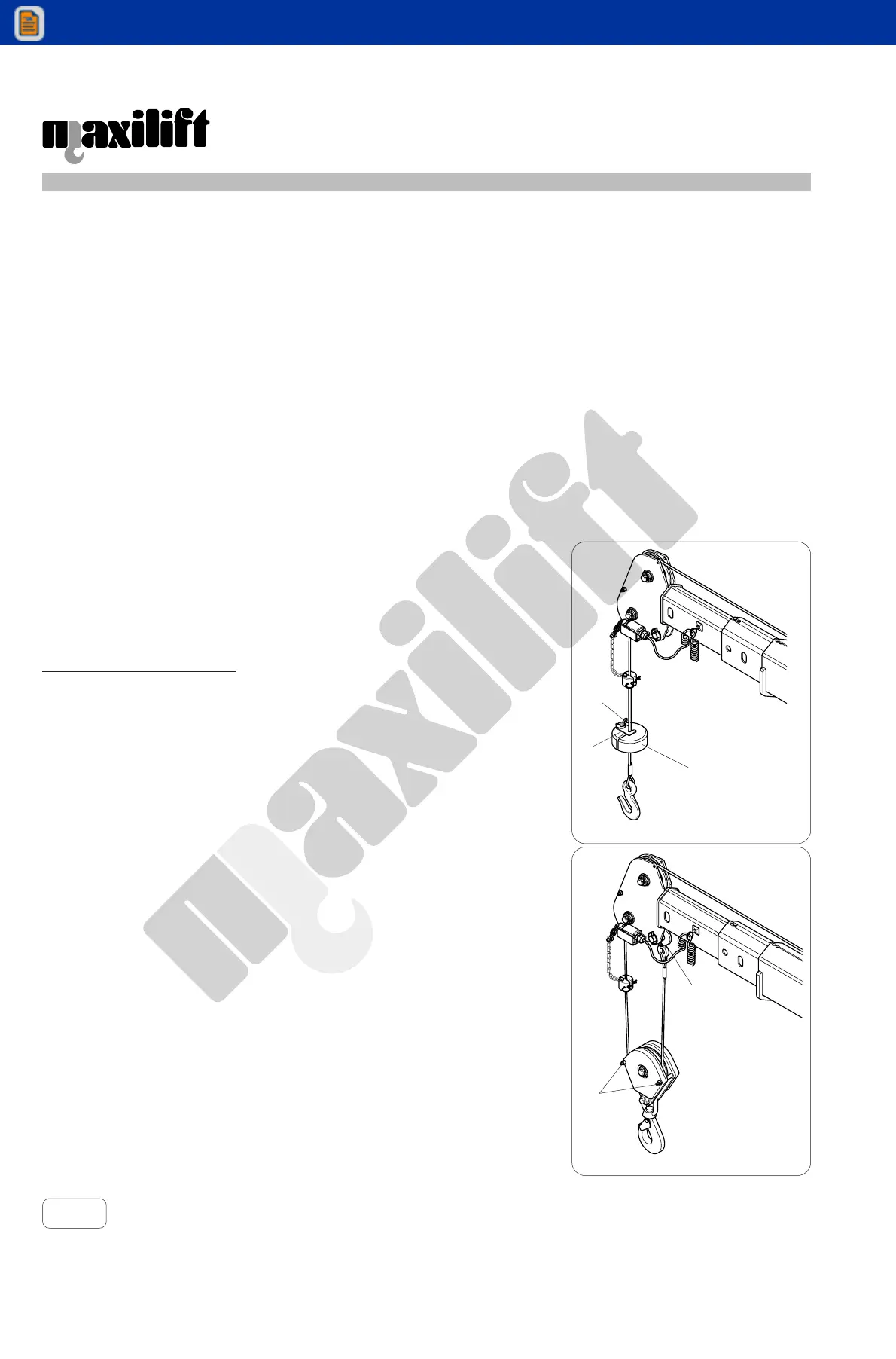

Pict. 5

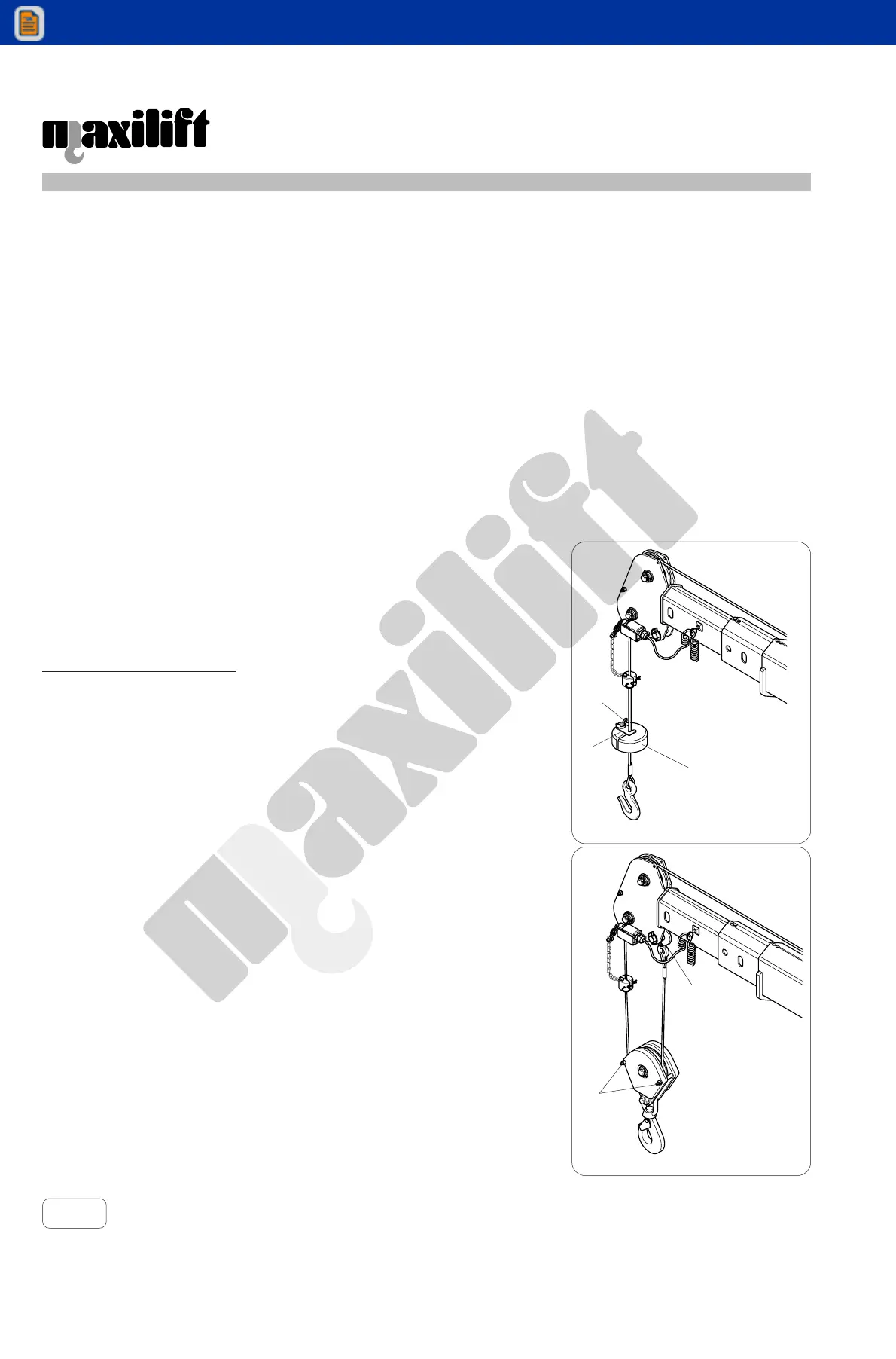

Pict. 4

1

2

3

4

5

Loading...

Loading...