21

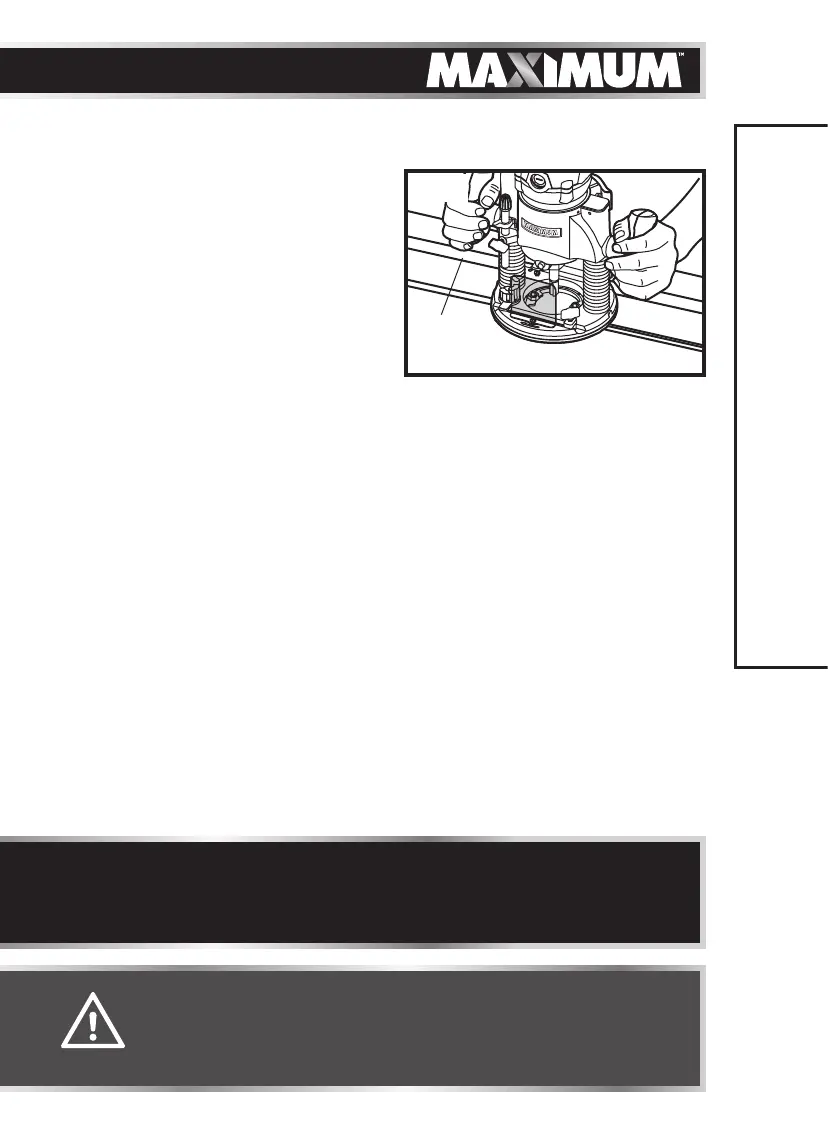

STARTING THE CUT

Much of routing is a trial-and-error

process of making various adjustments,

followed by test cuts as you become

familiar with all of your router’s

operational abilities. To avoid ruining

good material, make your test cuts on

scrap materials.

For ease of operation and to maintain

proper control, your router has two

handles, one on each side of the router

base. When operating the router, always

hold it firmly with both hands (Fig. 14).

DEEP CUTS

The proper cutting depth for each pass is always determined by the material, the

cutter bit size and type, and the power of the motor.

Always make several progressively deeper cuts: start at one depth and then

make several passes, each time increasing the cutting depth, until the desired

depth is reached.

Making a cut that is too deep will stress the router motor and the cutter bit, and

it may burn the workpiece and dull the cutter bit. It could also “grab” too much

of the workpiece, causing you to lose of control of the router, which may result in

a serious accident.

To be certain that your depth settings are correct, always make test cuts in scrap

material similar to your workpiece before beginning the final cutting operation.

Remember, knowing the right depth for each cut comes with routing experience.

OPERATING INSTRUCTIONS

WARNING!

• Before operating the router, follow all safety instructions in this

manual. Failure to do so could result in serious personal injury.

• Always be alert and watch what you are doing. Never operate the

router when you are fatigued or otherwise impaired.

NOTICE: Making test cuts is essential with most routing applications. Even

with careful set-ups, you won’t know exactly how the cut will go until you try

it out. A test cut will give a feel for the set-up, the router’s speed, the depth

of cut, and how the cutter bit reacts to the workpiece.

Edge

Guide

Edge with plunge base

g 14

Loading...

Loading...