47

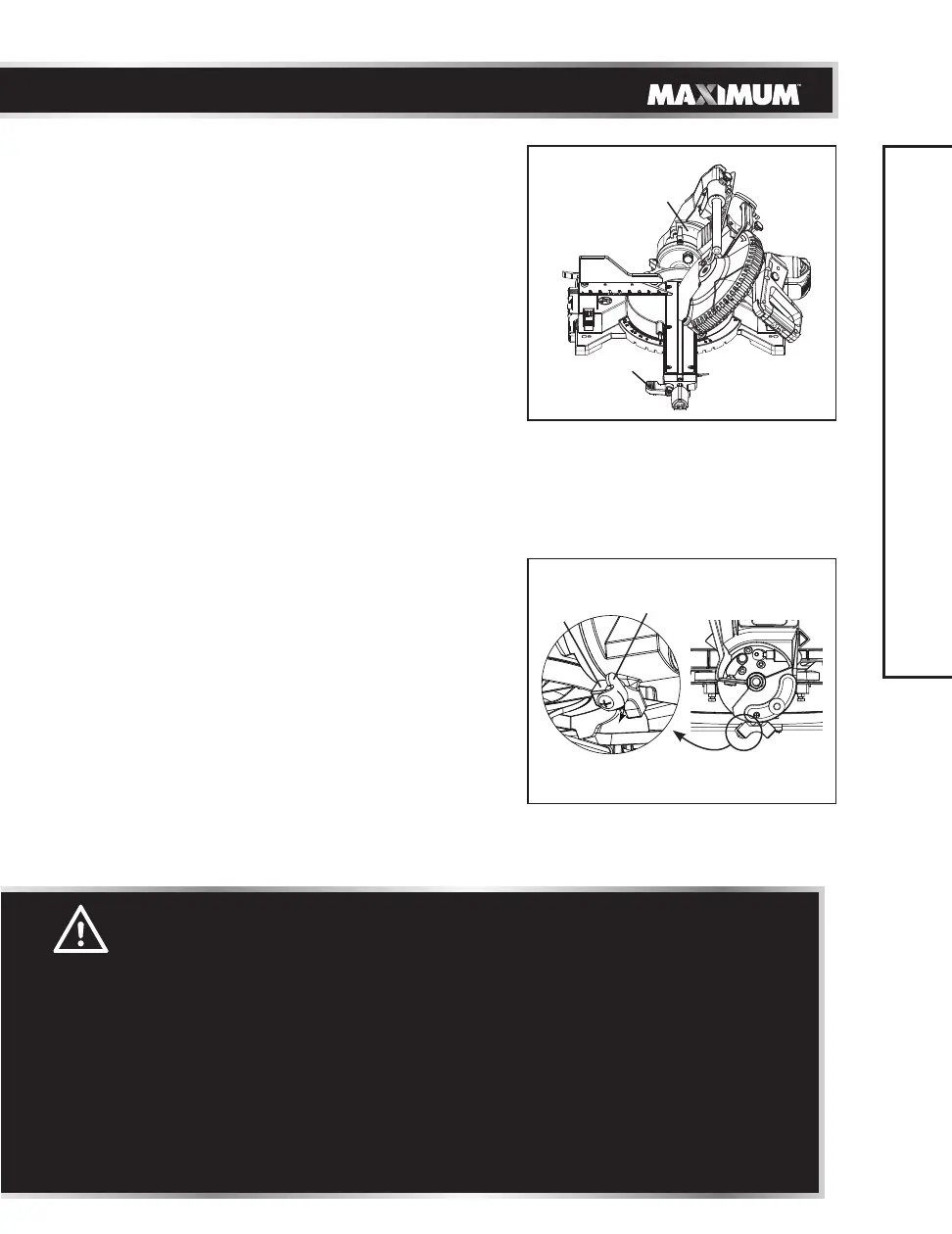

BEVEL CUT (Fig. 40, 41)

• When a bevel cut is required, loosen

the bevel locking handle (1) by turning

it clockwise.

• Tilt the cutting head to the desired angle,

as shown on the bevel scale (2).

• The blade can be positioned at any angle,

from a 90° straight cut (0° on the scale) to

a 45° left bevel. Tighten the bevel locking

handle (1) to lock the cutting head in

position. Positive stops are provided at 0°,

33.9° and 45°.

NOTE: The saw comes with a 33.9° bevel

detent pin for setting up crown moulding

cuts when the angle of the walls equals 90°.

• Turn the laser guide on and position the

workpiece on the table for pre-alignment of

your cut.

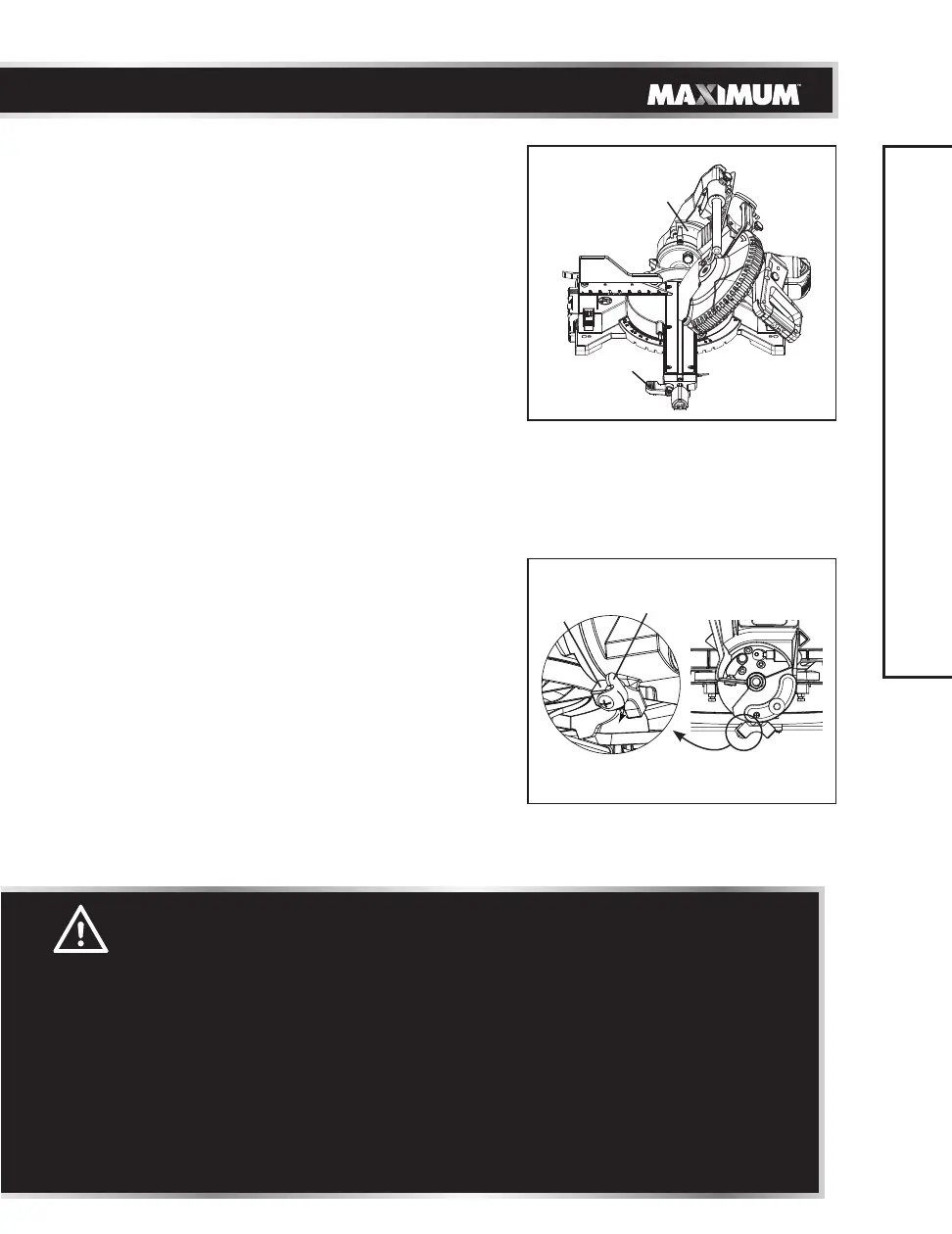

NOTE: If 47

° left bevel is necessary,

slide the

bevel stop plate (3) clockwise away from the

stop block (4) to achieve 47

° left bevel.

WARNING!

• The sliding fence must be extended to the left when making left bevel

cuts. The sliding fences note three bevel angles where the user must

adjust the fences to match the degree of the bevel cut. Failure to extend

the sliding fence will not allow enough space for the blade to pass

through which could result in serious injury. At extreme mitre or bevel

angles the saw blade may also contact the fence.

• The left sliding fence must be removed when making left bevel angle

cuts greater than 33.9° in combination with any right or left mitre angle.

This fence must also be removed whenever a 45° bevel angle is desired

with a mitre angle greater than 31.6°.

• The right sliding fence must be removed when making any right bevel

angle cuts.

Fig. 40

OPERATION

Fig. 41

3

4

1

2

Loading...

Loading...