51

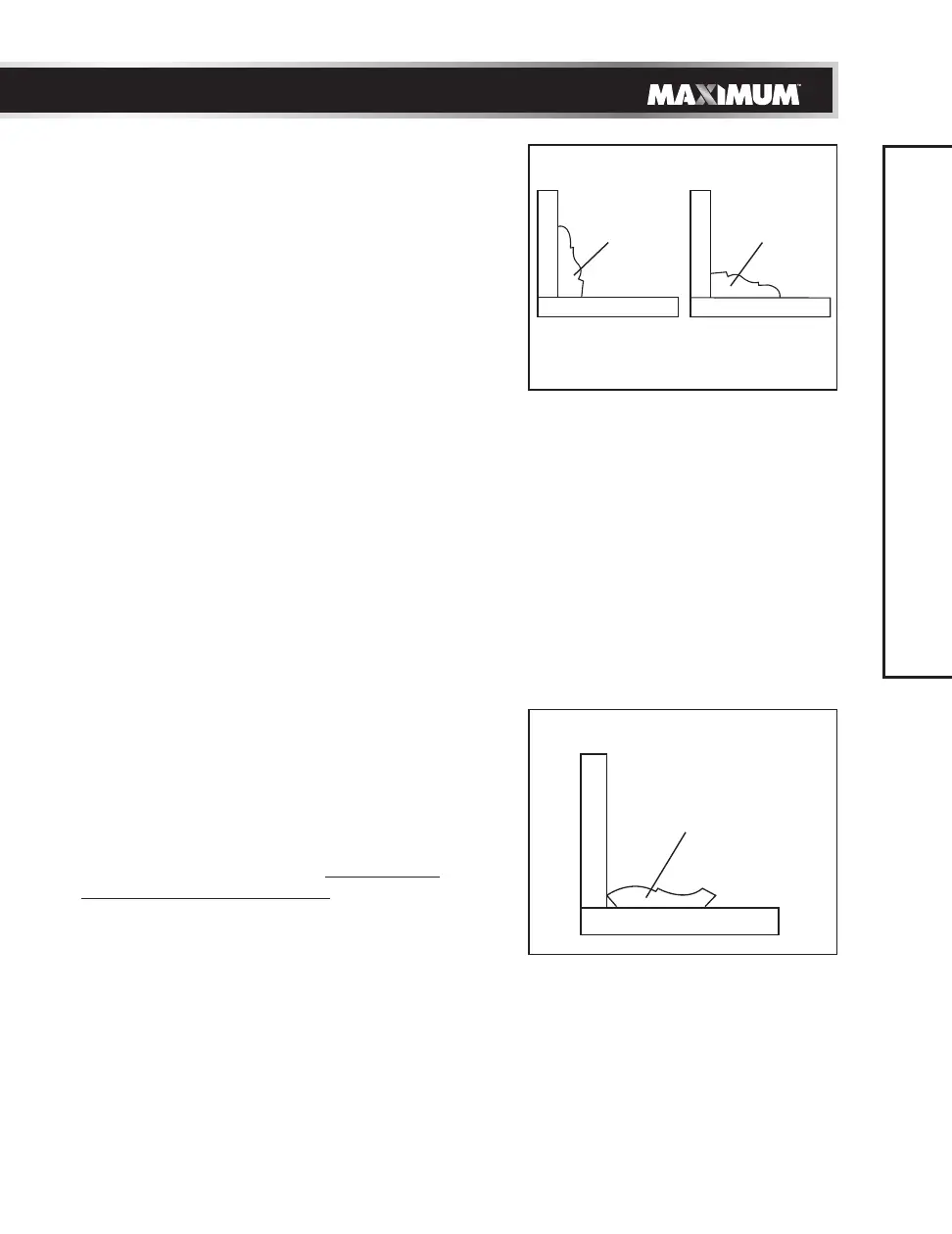

CUTTING BASE MOULDING (Fig. 48)

Base mouldings and many other mouldings

can be cut on a compound mitre saw. The

setup of the saw depends on moulding

characteristics and application, as shown.

Perform practice cuts on scrap material to

achieve best results:

• Always make sure mouldings rest firmly

against fence and table. Use hold-down,

crown moulding vice or C-clamps,

whenever possible, and place tape on the

area being clamped to avoid marks.

• Reduce splintering by taping the cut area

prior to making the cut. Mark the cut line

directly on the tape.

• Splintering typically happens due to an

incorrect blade application and thinness of

the material.

NOTE: Always perform a dry run cut so

you can determine if the operation being

attempted is possible before power is applied

to the saw.

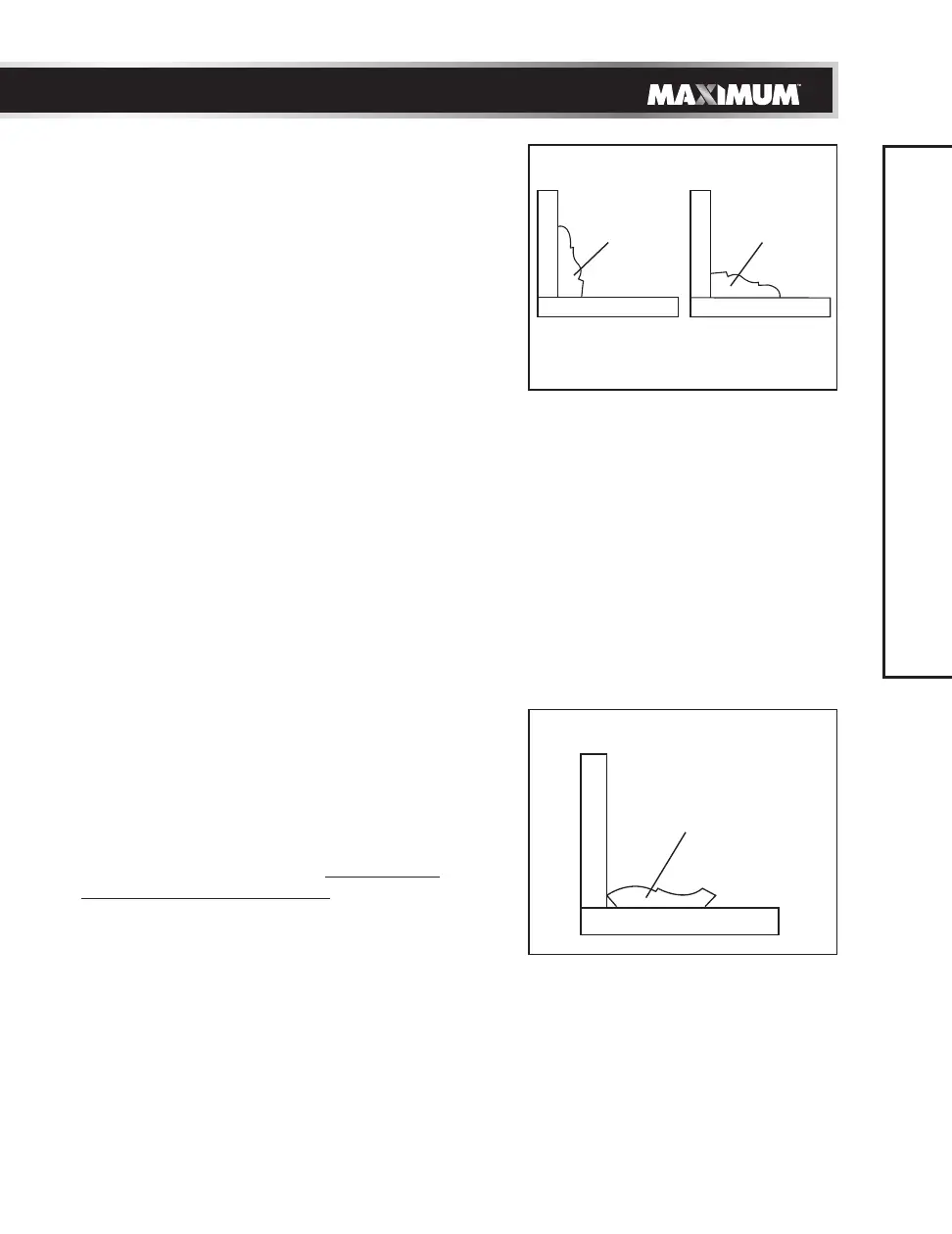

CUTTING CROWN MOULDING (Fig. 49, 50)

• Your compound mitre saw is suited for the

difficult task of cutting crown moulding.

To fit properly, crown moulding must be

compound-mitred with extreme accuracy.

The two surfaces on a piece of crown

moulding that fit flat against the ceiling

and wall are at angles that, when added

together, equal exactly 90°.

• Most crown moulding has a top rear angle

(the section that fits flat against the ceiling)

of 52° and a bottom rear angle (the section

that fits flat against the wall) of 38°.

Fig. 48

F

e

n

c

e

Mitre saw table

Mitre at 45°,

bevel at 0°

Mitre at 0°,

bevel at 45°

F

e

n

c

e

Mitre saw table

Workpiece

Workpiece

Fig. 49

F

e

n

c

e

Mitre saw table

Workpiece

OPERATION

Loading...

Loading...