11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

12

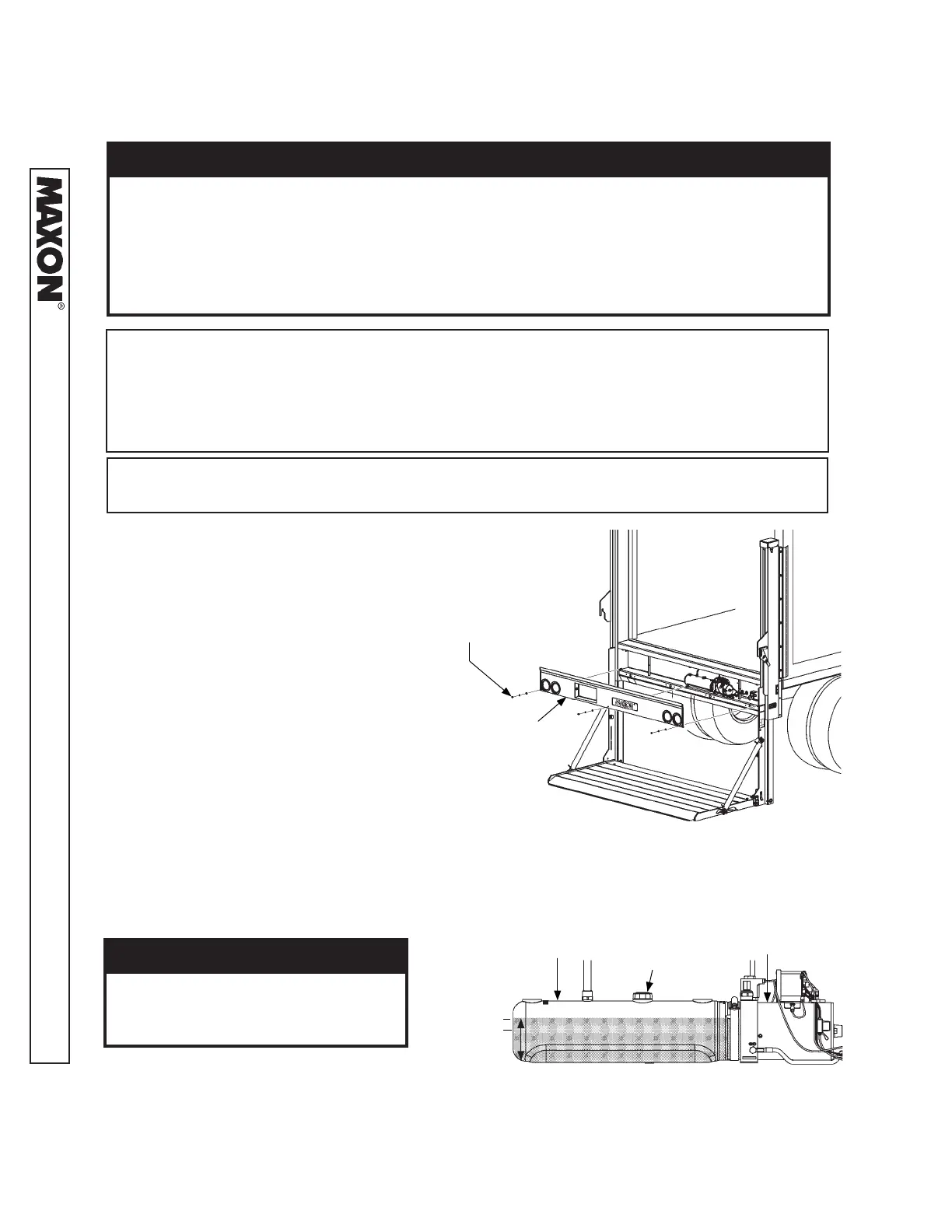

3-1/4” MIN

PERIODIC MAINTENANCE

CHECKING HYDRAULIC FLUID

4. If needed, add fl uid to the reservoir as

follows. Remove fi ller cap (FIG. 12-2).

Fill the reservoir with hydraulic fl uid to

level shown in FIG. 12-2. Reinstall fi ller

cap.

3. Check the hydraulic fl uid level in

reservoir as follows. With platform

on the ground, level should be as

shown in FIG. 12-2.

5. Bolt cover in place on the main

housing (FIG. 12-1). Torque the

5/16”-18 cover bolts from 10 to

14 lb-ft.

CAUTION

Main housing cover must be

correctly secured to prevent it

from becoming a hazard.

NOTE: If the hydraulic fl uid in the reservoir is contaminated, do the CHANGING

HYDRAULIC FLUID procedure in this section.

CAUTION

Keep dirt, water and other contaminants from entering the hydraulic system.

Before opening the hydraulic fl uid reservoir fi ller cap, drain plug and hydraulic

lines, clean up contaminants that can get in the openings. Also, protect the

openings from accidental contamination.

Never mix synthetic fl uids with conventional hydraulic fl uids. Hydraulic system

must be purged if the fl uids are mixed.

NOTE: Liftgate is shipped with Exxon Univis HVI-13 hydraulic fl uid in the hydraulic

cylinders. Exxon Univis HVI-13 hydraulic fl uid is recommended for operating

temperatures of -40 to +120° F. Refer to decal in pump box. Under certain

conditions, other brands and grades of oil may be used as substitutes for the

recommended oil. Refer to TABLE 13-1.

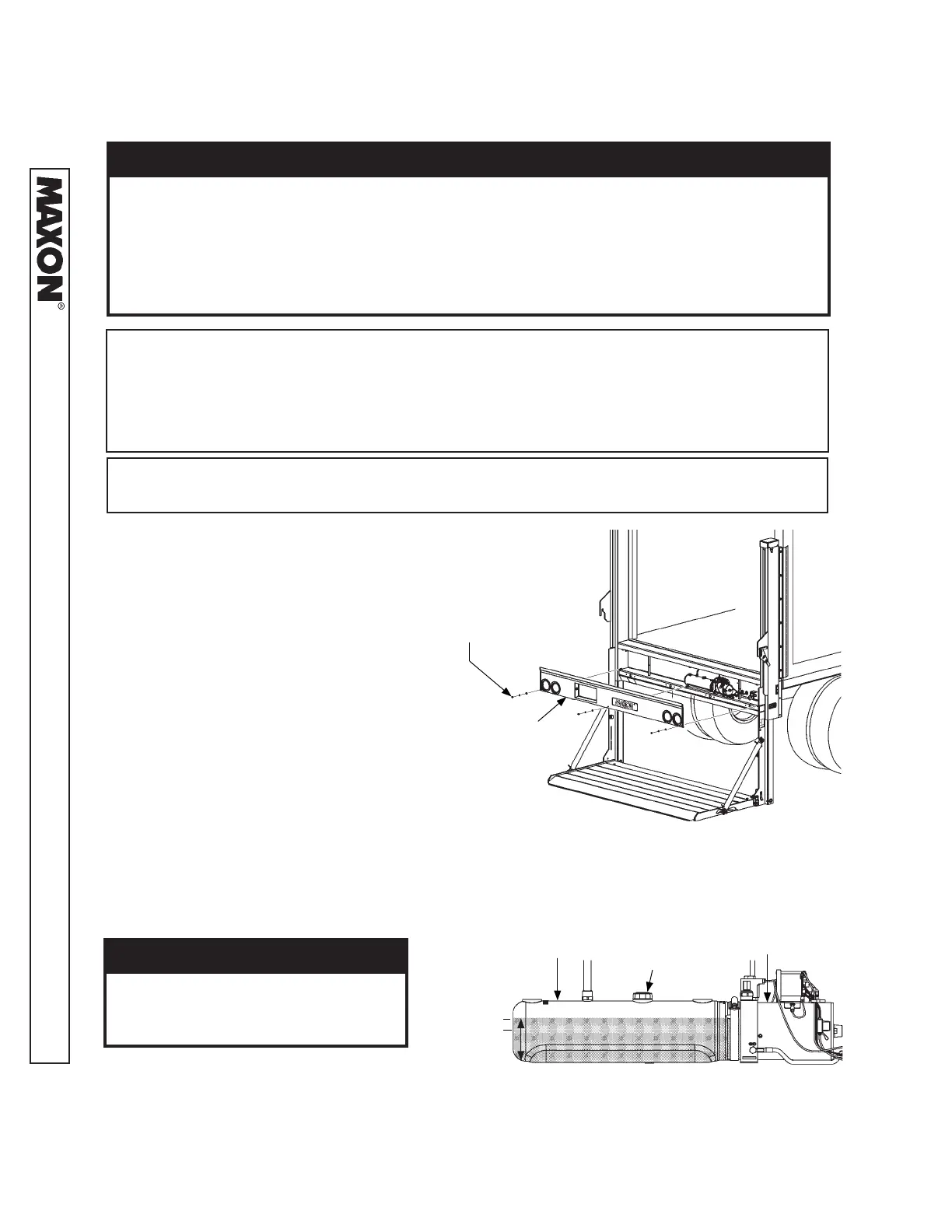

UNBOLTING/ BOLTING COVER

FIG. 12-1

2. Unbolt and remove cover

from main housing as

shown in FIG. 12-1.

1. Unfold and lower platform to

the ground (FIG. 12-1). Refer to

Operation Manual for detailed

operating instructions.

BOLT,

LOCK WASHER &

FLAT WASHER

(3 PLACES)

COVER

POWER UNIT FLUID LEVEL

(MANUAL CLOSE POWER UNIT SHOWN)

FIG. 12-2

3-3/4” MAX

POWER UNIT

(REF)

FILLER CAP

RESERVOIR

Loading...

Loading...