4.6 HOOK-UP WITH THE GAS SYSTEM

- Gas hook-up, transformation and testing must be done by professionally qualified personnel as per the manufacturer’s

instructions, in conformity with the standards.

- A fast-closing shut-off valve must be installed upstream from the oven.

- The oven must be supplied with one of the gases with the pressure specifications given in Table I on page 12.

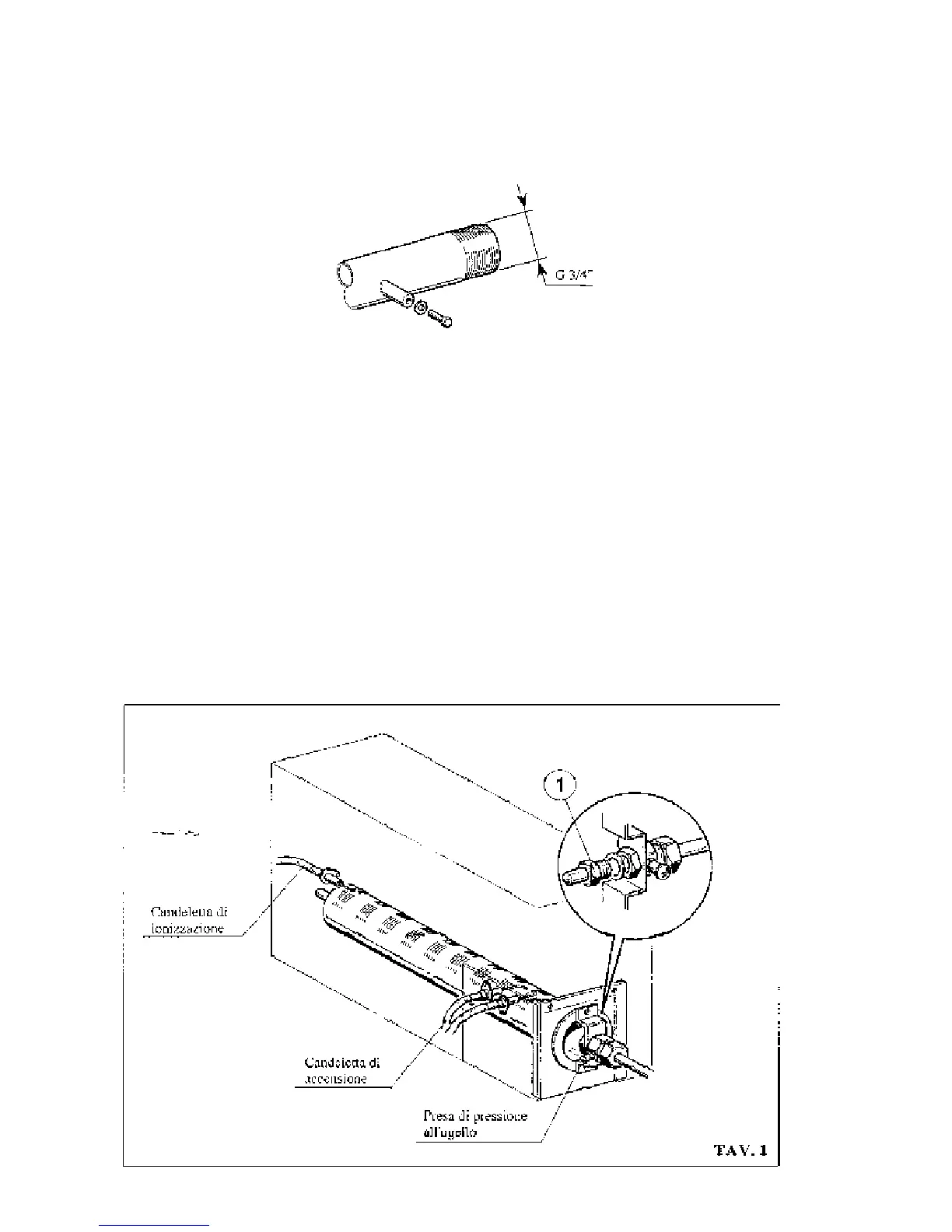

- The gas pressure is measured at the initial pressure socket (see figure below) or at the gas valve inlet with the burner on (Tab. 2).

- The oven is tested and fitted for operating with natural gas at 20 mbar or with liquid gas as required (see Table I). If the

installer hooks up with a different gas, he or she must carry out the operations given in section 4.6.1.

- Hooking up to the gas mains must be done with a metal pipe of suitable cross-section and a fast-acting shut-off valve must

be installed upstream to standards.

- After hooking up to the gas mains, check there is no leakage at the fitting points with the soap solution method. NEVER

WITH A LIT MATCH!

4.6.1 TRANSFORMATION FOR OPERATION WITH ANOTHER TYPE OF GAS

The nozzles supplied for different types of gas are marked and contained in a plastic bag. The size of the orifice is given in

hundredths of a millimetre.

4.6.1.1 REPLACING BURNER NOZZLE (FGMD67, FGMD67SC, FGMD107 and FGMD107SC)

- Remove the right panel.

- Remove the condensation tray. Strip the front portion of the combustion chamber.

- Unscrew the nozzle with a 17 mm. wrench (Tab.1 pos. 1).

- Replace the nozzle with the corresponding one for the chosen gas as indicated in Table II.

Don’t forget the aluminium gas seal washer!

Loading...

Loading...