MC-Fastpack Power-Tool

14 MC-Bauchemie Müller GmbH & Co. KG 01-2021

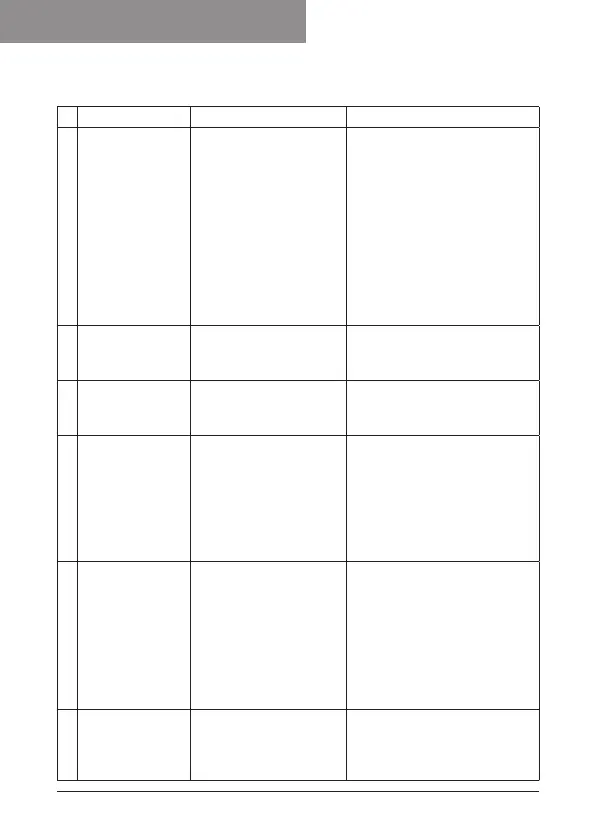

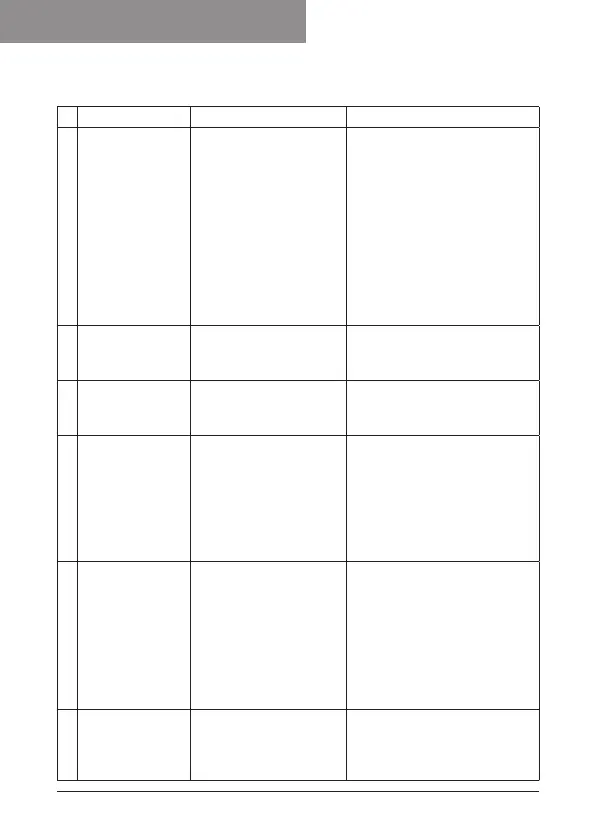

8) TROUBLESHOOTING

No Fault Cause Remedy

1 Plunger discs

cannot enter the

cartridge

• Cartridge not fully

inserted in cartridge

holder

• Foreign matter in

cartridge guide

• Wrong diameter of

plunger discs installed

• Check that the correct

cartridge holder is installed

and is not damaged. Push

cartridge fully down into the

cartridge sleeve.

• Remove foreign matter from

cartridge guide (do not use

sharp tools).

• Check the correct diameter of

plunger discs. Change plunger

discs if necessary.

2 Cartridge cannot

be removed from

the dispenser

• Plunger discs are still

in position inside the

cartridge

• Fully retract the plungers by

using the retract button (check

dispense volume indicator).

3 Dispensing is

interrupted

• Compressed air supply

has been interrupted

• Check compressed air supply

pressure. Check connection to

dispenser.

4 Unable to

discharge

material

• Material has cured in

the mixer

• Pressure not high

enough

• Replace the mixer. Refer to

mixer-open-time in technical

data sheet of materials to be

dispensed.

• Gradually increase the

pressure by turning the

pressure regulation valve.

5 Leaking air noise • Inlet pressure too high –

safety valve blowing o

• Leakage at compressed

air connection

• Leakage from handle

• Check and reduce inlet

pressure to adequate level.

• Check and tighten the adapter.

• If the source of air leakage is

inside the handle please send

the device to the manufacturer

or authorized service station

for inspection.

6 Uneven

dispensing speed

• Foreign matter in driving

unit /damaged sealing

• Send device to manufacturer

or authorized service station

for inspection (never use

solvents to clean the air path).

Loading...

Loading...