12

Trackability Adjustments

During playback of Phonograph Recordings, the

Diamond tip of the stylus assembly is subjected to all

kinds of extreme operating conditions. One of those

conditions is the forces constantly trying to push the

stylus up and out of the grooved wall of the recording.

The Tracking Force Pressure is applied in a downward

direction to keep the stylus in contact with the groove

wall. Another condition is the uneven side to side pres-

sure applied to the stylus as it tries to stay in contact

with both sides of the groove wall of the recording.

Refer to figure 33.

This is a function of all pivoting Tone Arms where

the headshell is usually angled inwards to minimize

the playback arc. The Anti-Skating Adjustment of the

MT10 Tone Arm permits equalizing for even side to

side pressure.

The correct amount of Tracking Force Pressure and

Anti-Skate Pressure varies with the exact shape of the

Diamond Stylus Tip, Tone Arm Characteristics and fi-

nally the audio signal (both frequency and amplitude)

contained in the groove wall of the record playing.

The way to achieve the best performance and the

least amount of Diamond Stylus Tip/Record Groove

wear is to use special test recordings, such as the

Shure Trackablity Test Record (TTR101). Both Track-

ing Force and Anti-

Skate Adjustments

are made as a result

of listening to the

specially recorded

tracks and following

the instructions to re-

duce different forms

of audible distortions.

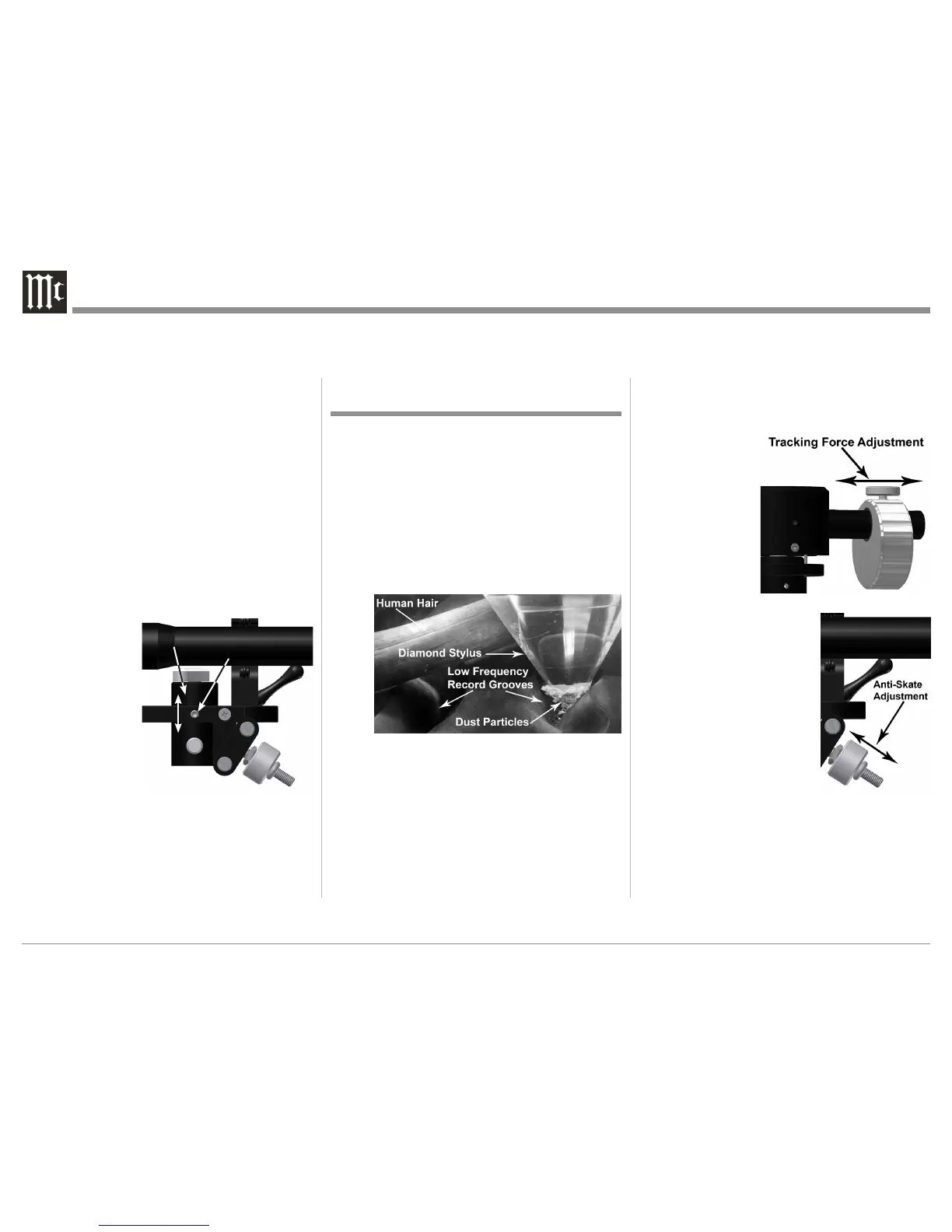

Refer to figures 34

and 35.

While making these

adjustments, do not exceed

the manufacturers recommend

Maximum Tracking Force Pres-

sure Setting.

Your McIntosh Dealer, using

Test Measurement Equipment

and Professional Test Record-

ings, can achieve via adjust-

ments, the best possible sound

quality from your record col-

lection and ensure the greatest

longevity.

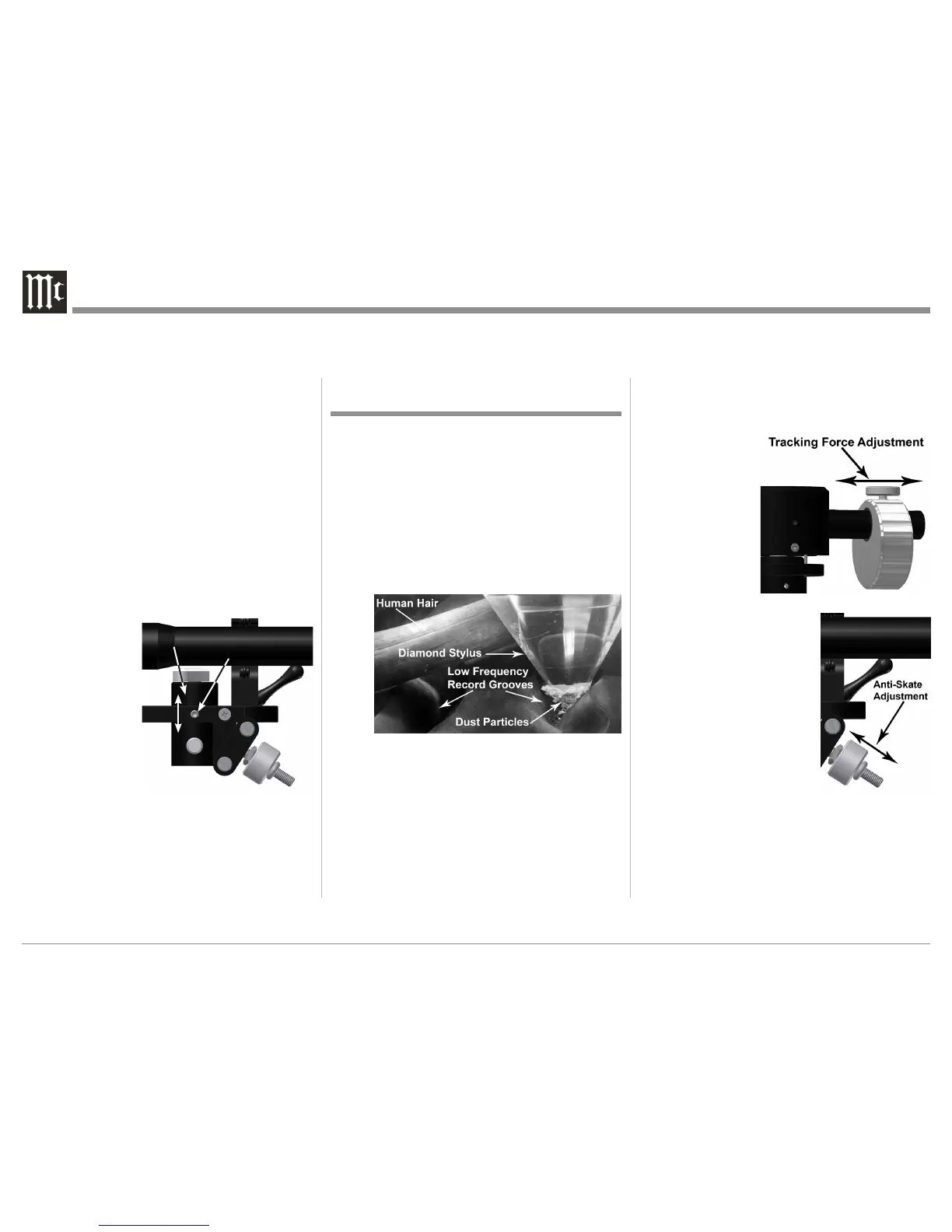

Figure 34

Figure 35

Figure 33

Tone Arm Lift Height

The MT10 Tone Arm Lift is pre-adjusted to accommo-

date the combined thickness of the supplied Turntable

Record Mat and Phonograph Records. If a different

Record Mat and/or thicker Phonograph Record are

used, there may not be sufficient clearance between

the Phono Cartridge Stylus and the Phonograph

Record surface with the Tone Arm Lift in the cue up

position. Perform the following steps to readjust the

Tone Arm Lift:

1. Secure the Tone Arm in the Tone Arm Rest.

Note: Before making any adjustments to the Tone

Arm Lift check to see if the Tone Arm is paral-

lel to the record surface when playing a record

first. See “Tone Arm Height” section on page

11.

2. Using the appropriate tool, carefully loosen the

Set Screw while

supporting the

bottom the Tone

Arm Lift. Refer to

figure 32.

3. Re-position the

Tone Arm Lift

Mechanism up-

wards slightly and

then tighten the

Set Screw.

4. Check the clear-

ance between the

Phono Cartridge Stylus and the Phonograph Record

surface with the Tone Arm Lift in the cue up posi-

tion. If necessary, readjust the position of the Tone

Arm Lift and re-check.

5. With the Turntable stopped and no Phonograph

record on the record mat, make sure the Phono Car-

Figure 32

Set Screw

Tone Arm Lift

tridge Stylus comes in contact with the record mat

with the Tone Arm Lift in the down position.

Loading...

Loading...