IOMM AGR AGR 055A through 100A 53

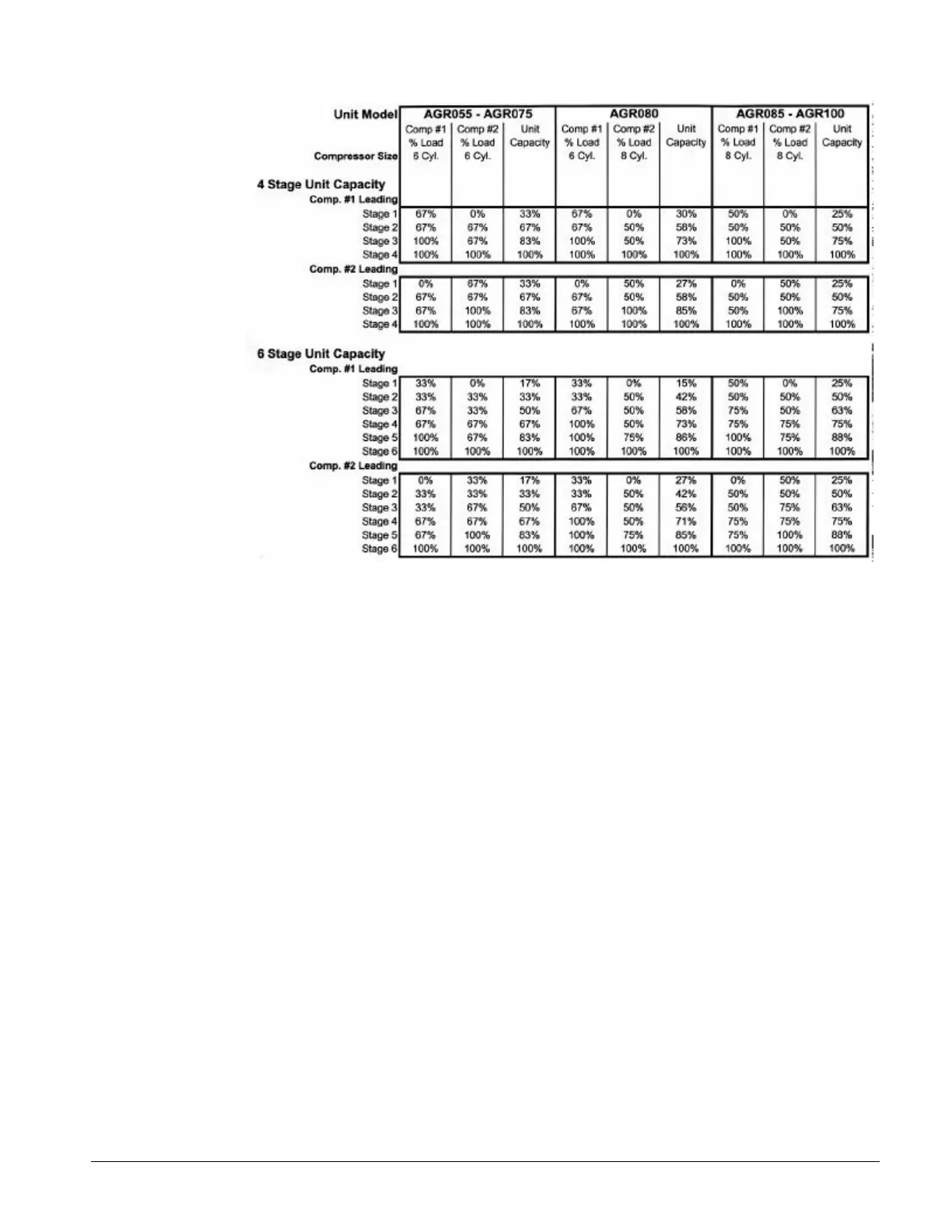

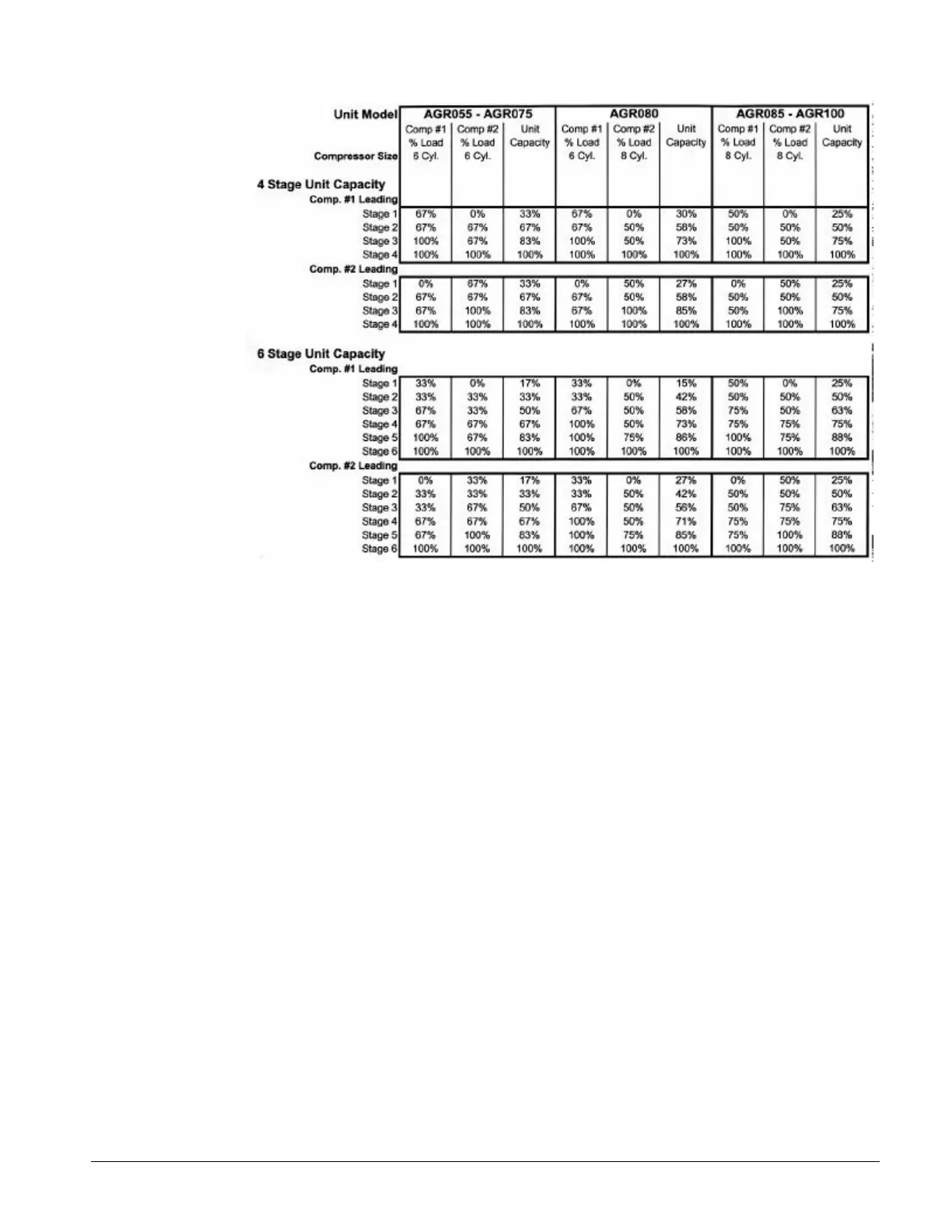

Table 16, System Staging and Unit Capacity

Pumpdown Control

The AGR units have a limited recycling pump down. The pump down is activated when a circuit’s

liquid line solenoid valve is de-energized. After the circuit’s liquid line solenoid valve is de-

energized, the operating compressor on that refrigerant circuit will operate until the low pressure

switch opens and stops that compressor. The compressor will cycle on if the evaporator pressure

exceeds the low pressure cut-in value. After a two hour time delay, the compressor will start again

to pump down the circuit (limited recycling pumpdown). After a two hour time delay, the

compressor will start if the Global UNT controller calls for cooling.

The Pumpdown and Stop switch will open its respective circuit’s digital input to the Global

UNT controller. This will open the associate circuit’s output and open the circuit’s solenoid valve.

If a compressor is operating on that circuit, the compressor will operate until the low pressure

switch stops the compressor. If a compressor is not running, the switch does not activate a

pumpdown for that circuit but will not allow the circuit to stage on and operate.

Certain alarm conditions will not permit chiller pumpdown. These alarm conditions are:

• High Condenser Pressure

• Bad Evap Pressure Sensor

• Compressor Motor Protect

• Freezestat Alarm

• Oil Pressure

• Phase Voltage Monitor (optional)

• Ground Fault (optional)

Loading...

Loading...