IMM AGS-2 21

Evaporator Freeze Protection

AGS chillers are equipped with thermostatically controlled evaporator heaters that help

protect against freeze-up down to -20°F (-28°C).

NOTE: The heaters come from the factory connected to the control power circuit. The

control power can be rewired in the field to a separate 115V supply (do not wire directly to

the heater). See the field wiring diagram on page 42. If this is done, mark the disconnect

switch clearly to avoid accidental deactivation of the heater during freezing temperatures.

Exposed chilled water piping also requires protection.

For additional protection, at least one of the following procedures should be used during

periods of sub-freezing temperatures:

1. Adding of a concentration of a glycol anti-freeze with a freeze point 10 degrees F below

the lowest expected temperature. This will result in decreased capacity and increased

pressure drop.

Note: Do not use automotive grade antifreezes as they contain inhibitors harmful to

chilled water systems. Use only glycols specifically designated for use in building

cooling systems.

2. Draining the water from outdoor equipment and piping and blowing the chiller tubes

dry from the chiller. Do not energize the chiller heater when water is drained from the

vessel.

CAUTION

If fluid is absent from the evaporator, the evaporator heater must be de-energized

to avoid burning out the heater and causing damage from the high temperatures.

1. Providing operation of the chilled water pump, circulating water through the chilled

water system and through the evaporator.

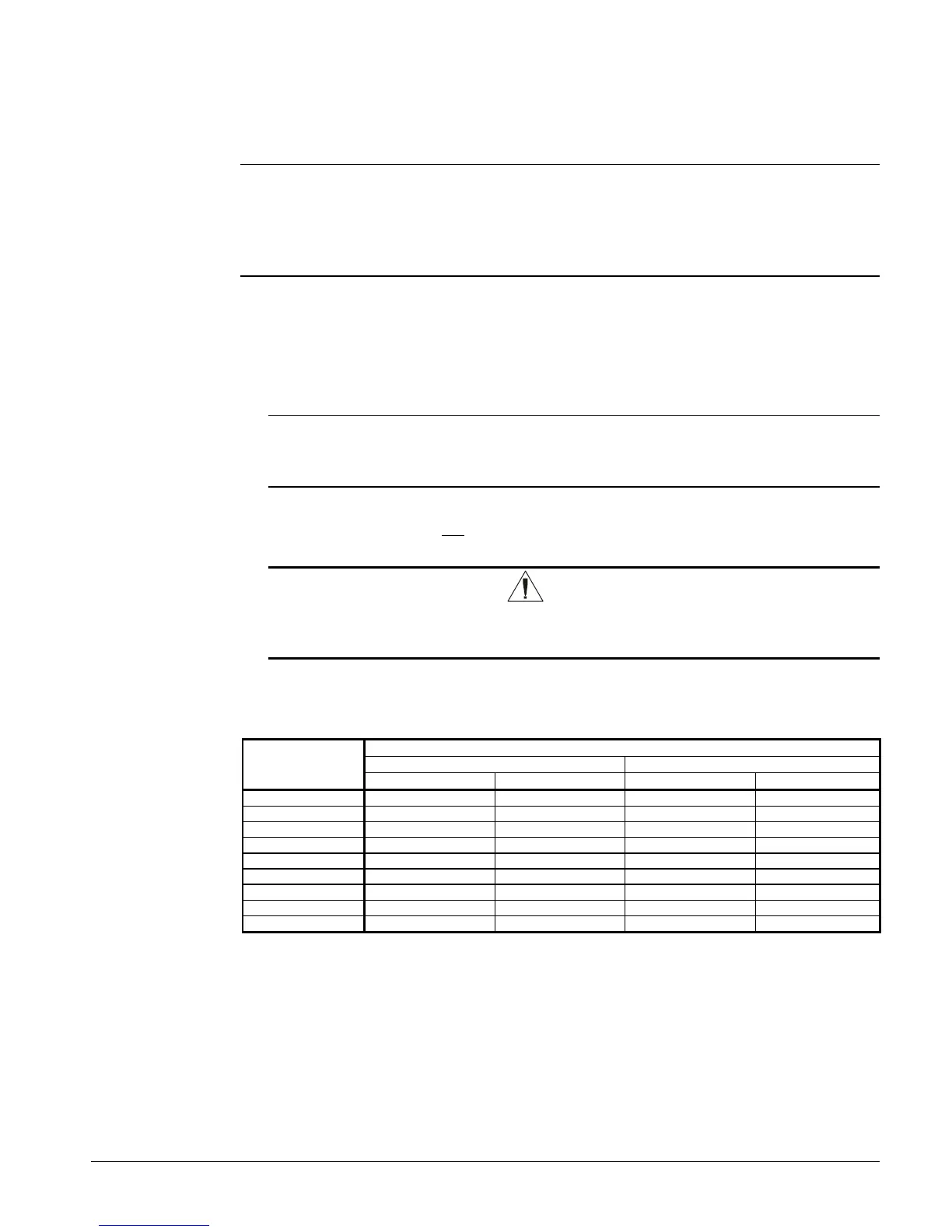

Table 12, Freeze Protection

Percent Volume Glycol Concentration Required

For Freeze Protection For Burst Protection

Temperature

°

°°

°F (°

°°

°C)

Ethylene Glycol Propylene Glycol Ethylene Glycol Propylene Glycol

20 (6.7) 16 18 11 12

10 (-12.2) 25 29 17 20

0 (-17.8) 33 36 22 24

-10 (-23.3) 39 42 26 28

-20 (-28.9) 44 46 30 30

-30 (-34.4) 48 50 30 33

-40 (-40.0) 52 54 30 35

-50 (-45.6) 56 57 30 35

-60 (-51.1) 60 60 30 35

Notes:

1. These figures are examples only and cannot be appropriate to every situation. Generally, for an extended margin of

protection, select a temperature at least 15

°

F lower than the expected lowest ambient temperature. Inhibitor levels

should be adjusted for solutions less than 25% glycol.

2. Glycol of less than 25% concentration is not recommended because of the potential for bacterial growth and loss of

heat transfer efficiency.

Loading...

Loading...