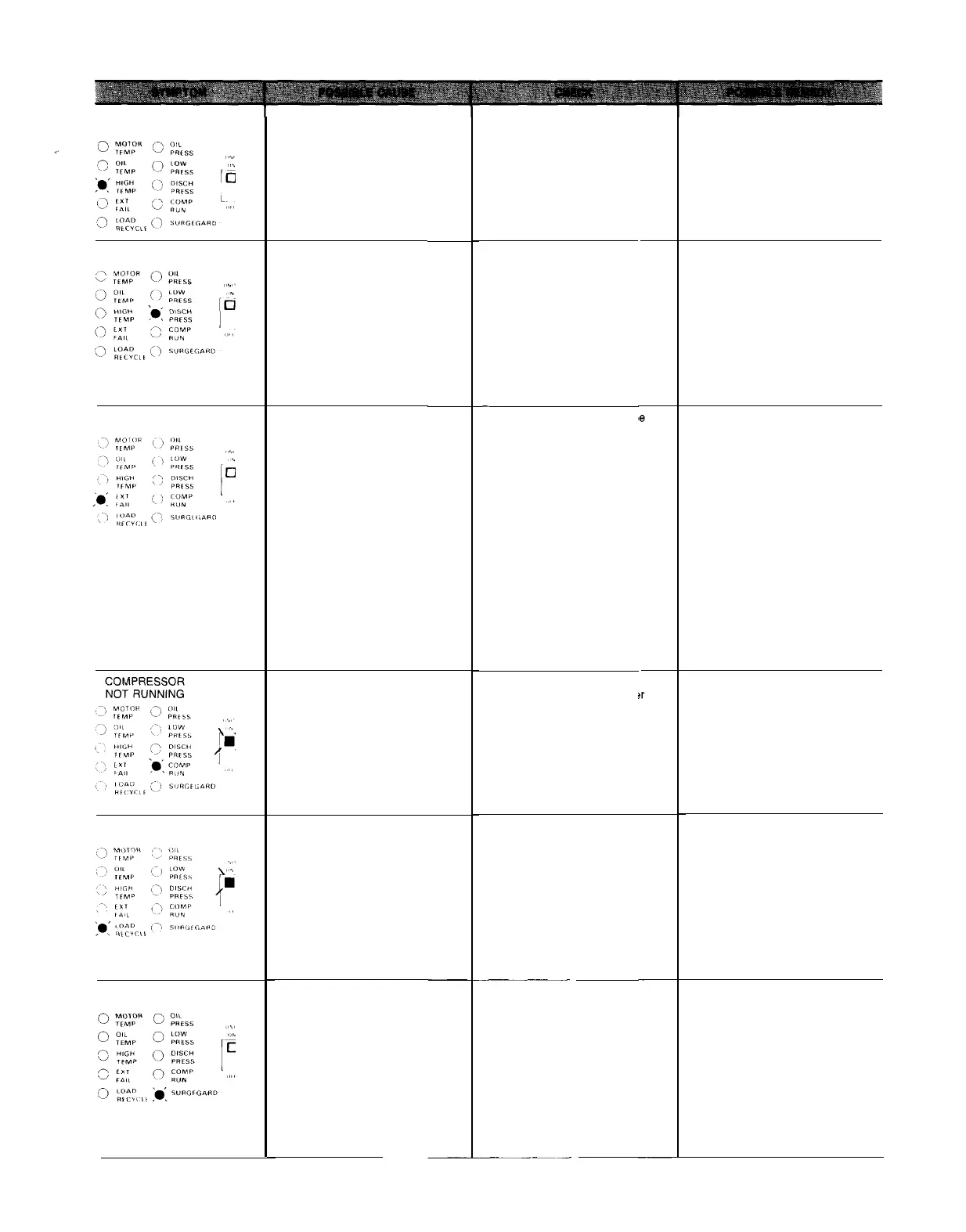

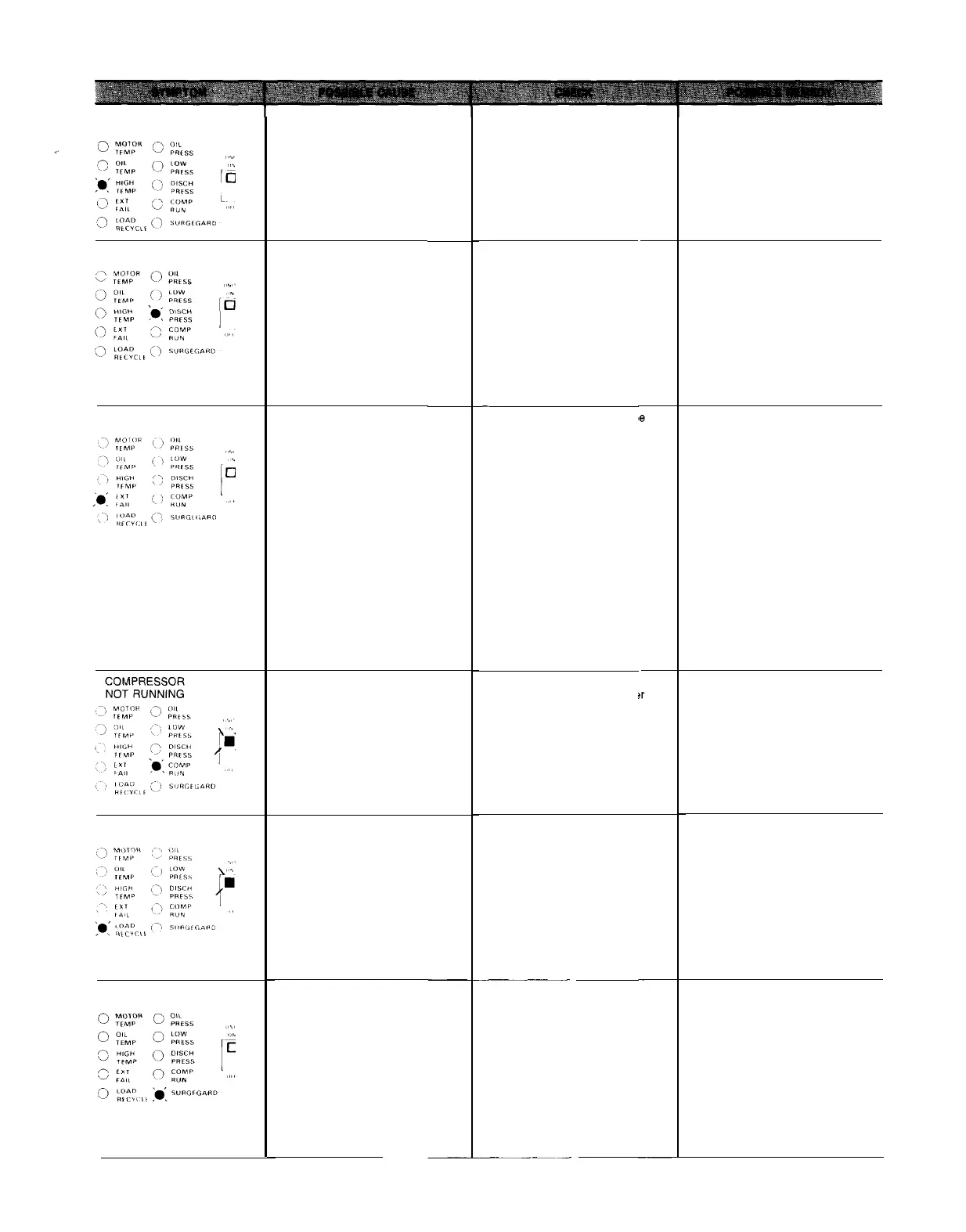

FIGURE 13 Continued. TROUBLESHOOTING

GUIDE

DISCHARGE

TEMPERATURE

1.

Low refrigerant charge.

2. Low refrigerant flow.

3. Condenser water flow too lo

w.

re too

4. Condenser water

temperatu

high.

1. Check charge.

2. Check superheat.

3. Check water strainer and

val

positions.

4. Examine

cooling

tower

5. High suction superheat. 5. Faulty

expansion

valve(s).

DISCHARGE PRESSURE

1.

Cooling tower problem.

2. Low condenser water flow.

3. Fouled, dirty tubes.

4. Refrigerant overcharge.

5. Warm chilled water (startup)

I.

la. Check tower water bypass.

b Check tower operation.

2 Pump,

strainer

3 Measure condenser water pr

sure drop

4. Check

subcooling.

5 Water temperature.

6. Air

in

refrigerant system.

EXTERNAL FAILURE 1. Power interruption (restored

voltage dip.

)

or

2. Low water flow.

6. Overall temperature and

pressures

-

1. Relays

R1

R2,

R5,

R7 will b

de-energized

and open.

2a Check water valves.

b. Flow switch malfunction.

c. Water

strainer

dirty.

d. Fouled tubes

3. No water flow

4. Defective

R7

relay.

5. Flow

switch

open.

6. Pump interlocks open.

7. Compressor starter

8 Power single phase.

3a. Pumps.

b. Valve

position

c. Pump starters

d. Condenser pump relay.

4. Check relay operation

5.

Circuit

continuity.

6.

Circuit

continuity.

7a.

Overloads tripped

b. Incomplete transition.

8a. Compressor motor.

b. MCR

failure

1.

The compressor starter has

energized but the

compress

does not start.

This

symptom

remain for 60 seconds at wh

time

the control circuit

willI

s

off and the external failure Ii

will

go on.

been

or

will

ich

witch

ght

1a Starter and MCR relays

b. Disconnect or

circuit

breakt

open.

c

O.L

tripped

LOAD RECYCLE

1 Normal shutdown

2. Load recycle thermostat.

3. Anti recycle thermostat.

1 Chilled water temperature

satisfied.

2a. Setting drift

b. Loss of bulb charge.

3a.

Time

delay not yet

timed

o

4. Low source water temperatu

,rere

(Templifier).

b. Too fast response to load

changes.

4. Source water temperature.

SURGEGARD

1.

Dirty

condenser.

2.

High

pressure lift

______-

1.

Condenser tubes

2 Water

temperatures.

3. Refrigerant overcharge

4. Defective R5 relay

5. Low condenser water flow

6. Open thermistor

circuit.

7.

Cooling

tower.

8 Faulty Surgegard relay

___

3.

Discharge

pressure

4 Relay

action

5 Strainer, valves

6. Check

circuit

7 Water level

8 Interchange

Guardistor

Surgegard relays

_____-

ve

es-

ut

1. Adjust as

required.

2. Adjust expansion valve

3. Clean strainer is dirty, open

valves if partially closed.

4. Adjust tower control as required.

5. Repair or replace.

la. Adjust or replace control

b. Clean or repair,

2. Repair, clean.

3. Clean tubes.

4. Adjust refrigerant charge.

5. Regulate flow to depress

temperature.

6. Purge air.

1. Push reset button

2a. Properly position valves.

b. Repair flow switch.

c.

Clean

strainer

d. Clean tubes.

3a. Repair or restart.

b. Open valves.

c. Reset OL; repair interlocks

d. Repair, replace.

4. Replace relay.

5. Correct switch

action.

6. Repair, replace.

7a. Reset or recalibrate.

b. Reset or repair starter

8a. Call

McQuay

Service.

b. Repair or replace.

1 a. Repair as required.

b. Close switch or circuit breaker.

c. Reset

1. None required.

2a. Recalibrate control.

b. Replace LRT.

3a. Wart for 20 minutes off

time

delay.

b. Adjust controls.

4 Check heat source

1.

Clean.

2. Reduce difference between

enter-

ing/leaving water temperatures.

3. Reduce

refrigerant

charge.

4.

Replace.

5. Clean

strainer,

open valves

6Correct.

7. Adjust makeup control.

8. Replace fault relay.

IM

307

/

Page 21

Loading...

Loading...