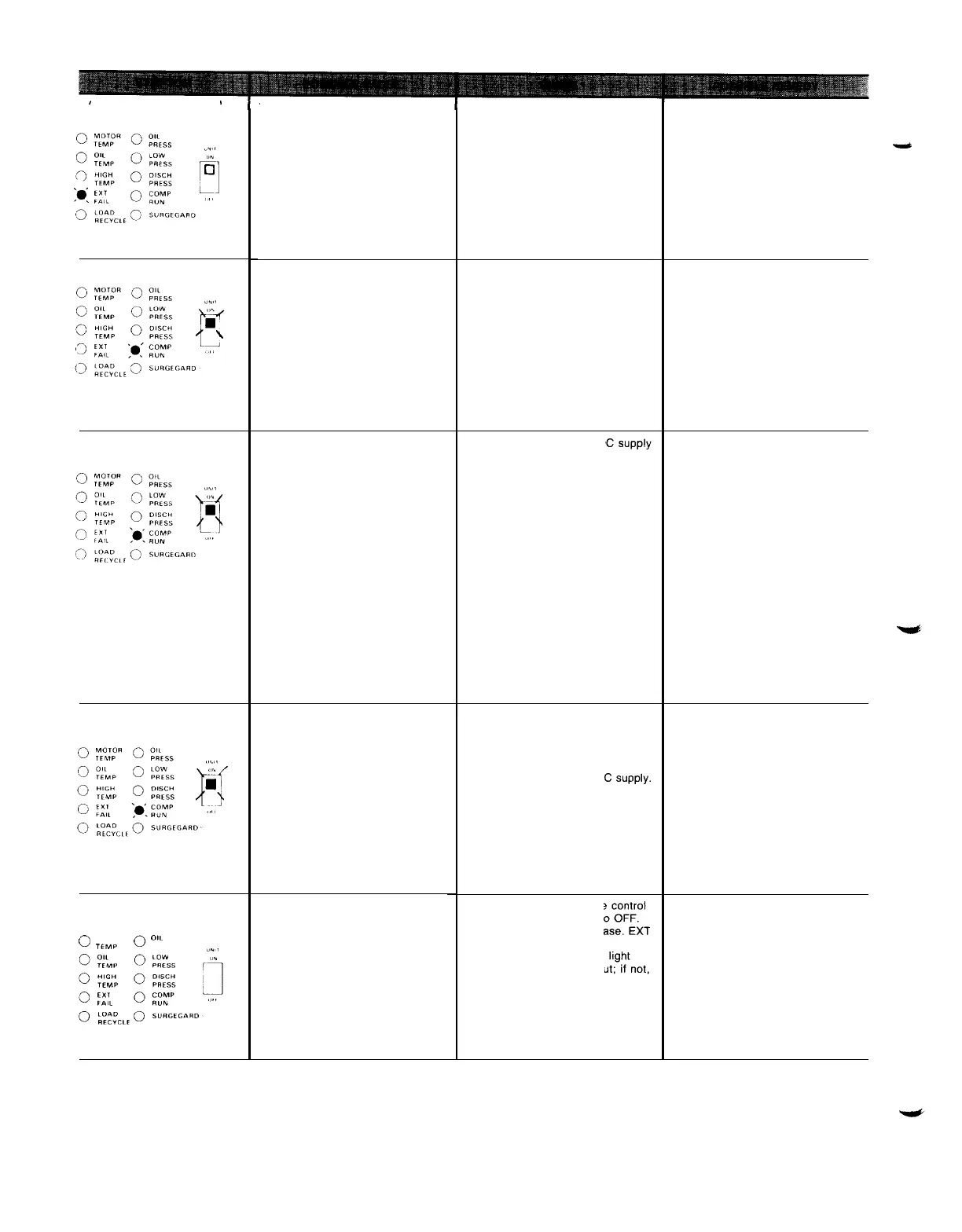

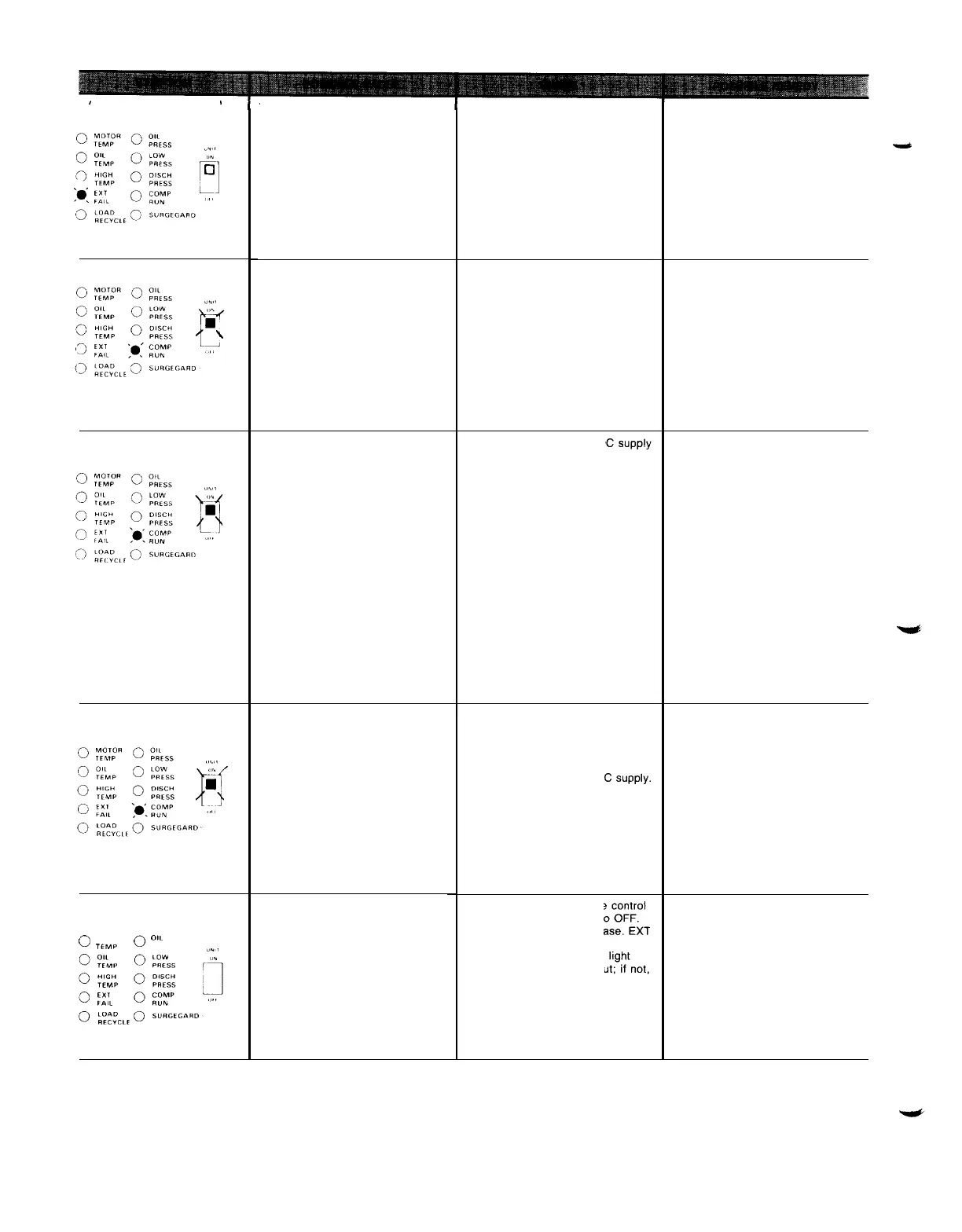

FIGURE 13 Continued. TROUBLESHOOTING GUIDE

COMPRESSOR STARTER

OVERLOAD TRIPPED

HUNTING

COMPRESSOR

WILL NOT LOAD

COMPRESSOR

WILL NOT UNLOAD

CANNOT RESET

CONTROL CIRCUIT

0

MOTOR

TtMP

0

OIL

PRESS

“*,,

1. Motor circuit problem.

2. Overload relay calibration.

3. Current

limit

set too high

in

control module.

4. Faulty current transformer (C.T.).

5. Single phase.

1

Capacity control vane speed.

2. Fast pulse rate (control module).

3 Faulty expansion valves

4. Fluctuating evaporator water flow.

5. Low

refrigerant charge

6. Low condenser water temperature

1. Faulty control module

2. Shorted sensor circuit (chiller)

3. Open sensor

circuit

(Templifier).

4. Wrong module jumper con-

nections.

5. Defective SB solenoid coil

6. Loss of CT voltage.

7. SB needle valve closed/

restricted.

8. Faulty relay

R4.

9. Low refrigerant charge.

10. Vane seal leakage.

11. Faulty LPO switch.

1. Open sensor

(chiller)

2. Shorted sensor circuit (Templifier).

3. Faulty control module.

4. Defective SA solenoid coil.

5. Faulty

4-way valve.

6. SA needle valve closed/restricted.

7. Vane damage

8. Wrong module jumper connection.

1. Faulty relays

R1

R2,

R5,

R7.

1.

Check continuity.

2.

Setting, dashpot

oil

level.

3a. Check resistor setting a

b. Check module setting

4.

Secondary output

5.

Fuses

1.

Vane operation.

2. Measure pulse rate.

3. Observe suction pressure

4. Evaporator pressure drop

5.

Superheat, subcooling

6..

Measure temperature.

1

a. Check + 20

&

+

6.2 VD

b. Check load

action

2. Remove one sensor

lead

3. Jumper COM

&

ISA.

4. Verify connections.

5. Solenoid

action

6. Measure at

1WHT

&

3B

7. Open wide.

8. Check relay

9. Superheat.

IO. Mechanical action.

Il. Check switch junction.

1.

Jumper +6.2

&

ISA

2.

Remove one sensor lead.

3a. Check

+

20

&

+

6.2 VD

b. Check load action

4. Check solenoid action.

5. Valve operation.

6. Open wide.

7.

Mechanical action

8

Verify connections

1. To check relays, energizt

power and on/off switch t

Install each relay

in

R7 b

FAIL light should glow. P

RESET button. EXT FAIL

should go out and stay

o

relay is faulty.

1.

Contact McQuay Service.

2. Reset, add dashpot oil.

3a. Reset.

b. Recalibrate control module.

4. Replace.

5. Correct fault.

1. Reset vane speed needle valve

2. Adjust to slower rate.

3. Repair, replace.

4. Correct flow deficiency.

5. Adjust refrigerant charge

6. Adjust tower controls.

la. Replace module.

b. Replace module.

2. If compressor loads, replace

sensor.

3. If compressor loads, replace

sensor.

4. Correct pin connections.

5. Replace.

6. Reset or replace

7. Clean and reset.

8. Replace

9. Adjust charge.

10. Call McQuay Service.

11. Replace.

1.

If compressor unloads, replace

sensor.

2.

If compressor unloads, replace

sensor.

3a. Replace module.

b. Replace module.

4. Replace

5. Repair, replace.

6. Clean, reset.

7. Call McQuay Service.

8. Correct pin connections.

1.

Replace faulty relay.

Page 22 /

IM

307

Loading...

Loading...