Page 7

• Where required by local codes, the ducts

can be sleeved inside the edge of the vent

cowl collars.

For this installation, the OUTSIDE

DIMENSION of the ducting, when viewed

from the front of the machine, should be

3-3/4”W x 15-3/4” D. The duct should

overlap the inside of the vent cowl collar

by a maximum of 1/2” to avoid interfering

with the baffle.

3. Install the ducts to the vent cowl collars.

4. Secure the ducts to the collars using sili-

cone sealant.

5. The baffles cannot be properly adjusted

until the machine is turned on. Refer to

Section 3.17, “Final Assembly.”

3.6 Booster Heater Placement

For units that are not equipped with an exter-

nal booster heater (for instance, when using

a building’s boiler as a 180°F water supply),

skip ahead Section 3.7, “Accessing the Util-

ity Connections.”

The booster heater should be positioned at

the unload end of the machine, close to the

water inlet access panel. Meiko recommends

a maximum pipe length from the booster to

the machine’s water inlet of 48”. If a longer

pipe run is necessary, Meiko recommends the

use of pipe insulation to minimize heat loss.

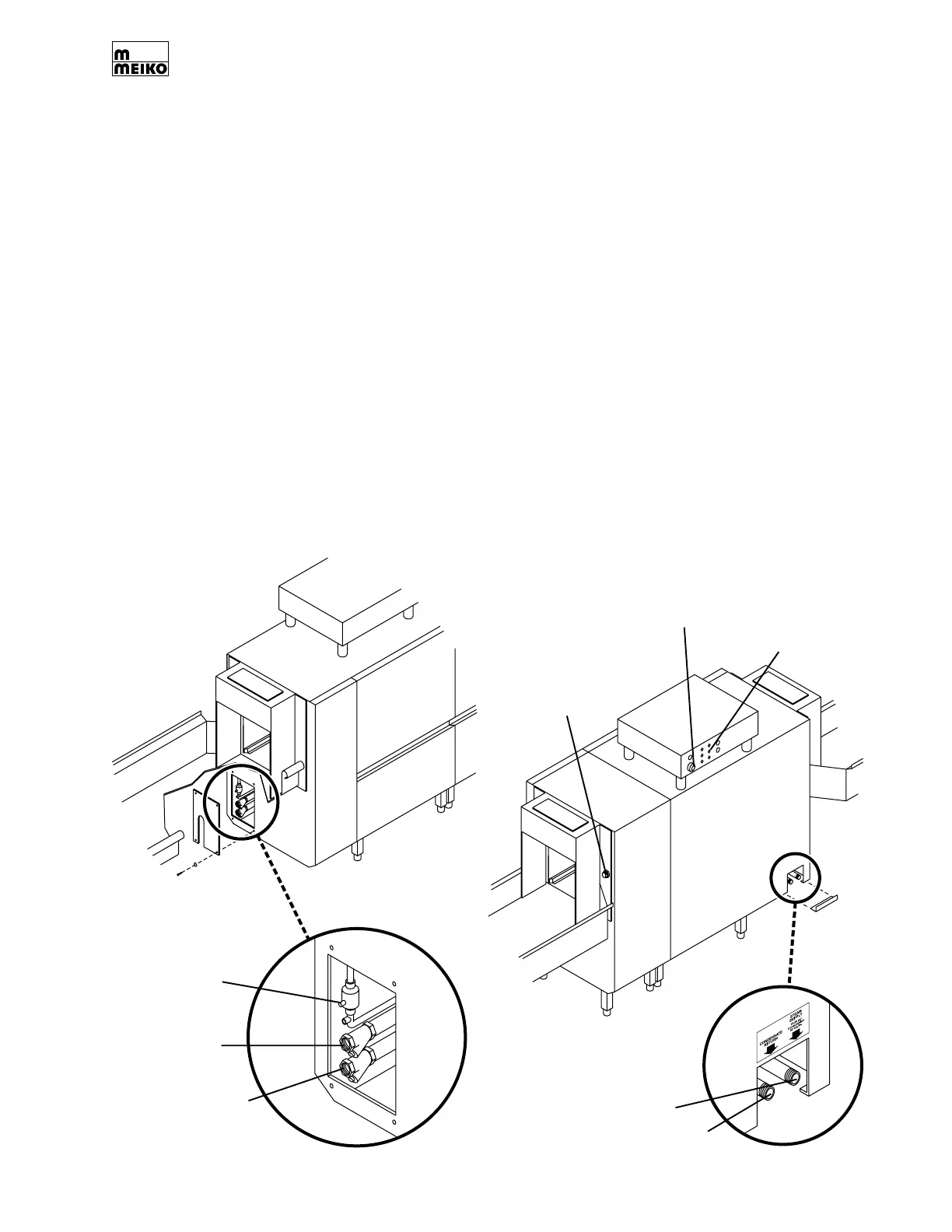

3.7 Accessing the Utility Connections

The utility connections for the machine are

shown in Figure 3-4.

Figure 3-4: Accessing utility connections

Remove

access

panel

UNLOAD END

(VIEWED FROM

FRONT)

Rinse aid

connection

Hot (180°F) water

connection

Warm (110-140°F)

water connection (if

machine is equipped

with prewash)

LOAD END (VIEWED FROM REAR)

Main electrical

supply strain

relief

Additional holes for

detergent pump and

accessory wiring

(covered with blind

plugs)

Machines without

prewash: Dummy plug in

wall for direct detergent

injection

Machines with prewash:

Pre-plumbed raceway

for detergent tubing

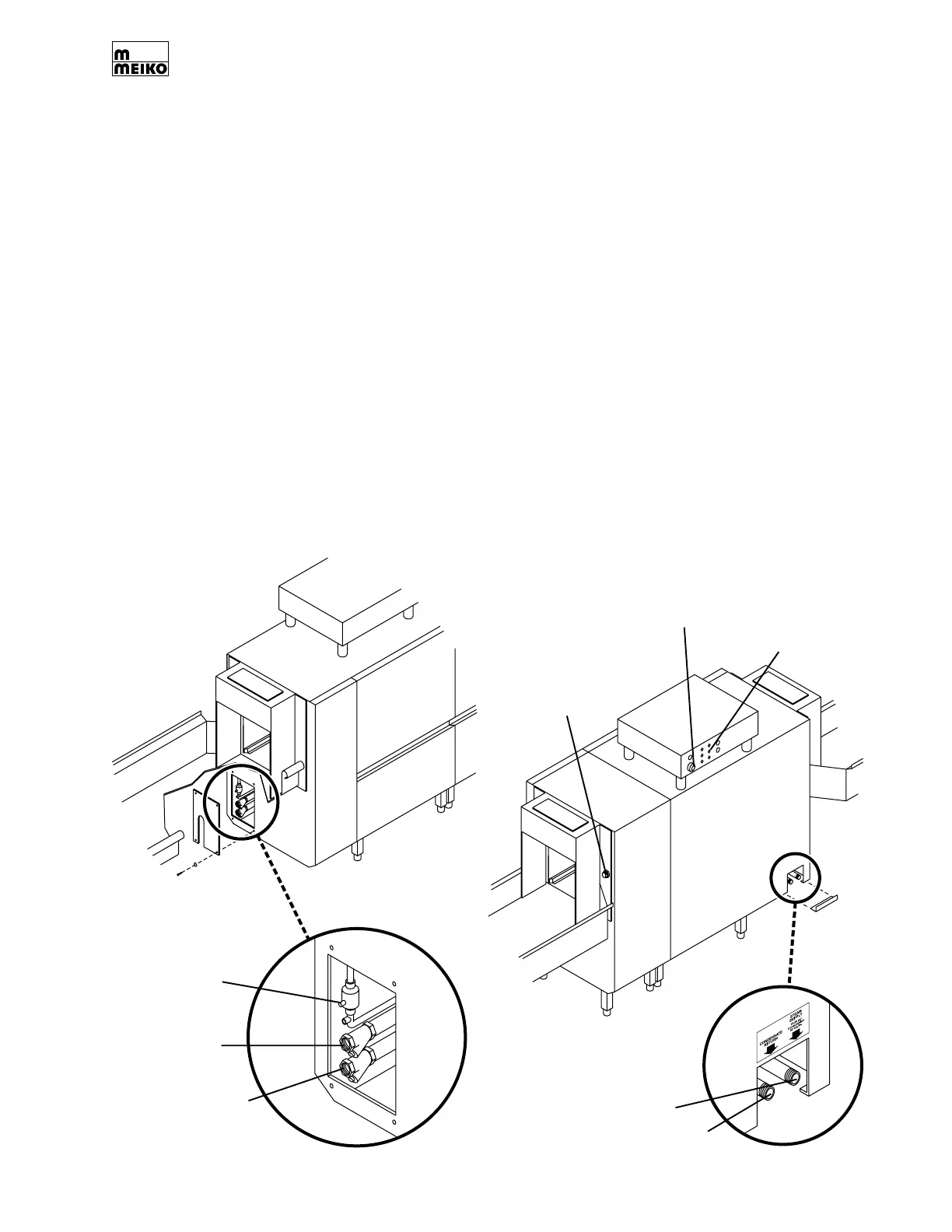

SECTION 3 - INSTALLATION

Steam supply line (outboard)

Steam condensate return (inboard)

Remove

access

panel

UNLOAD END

(VIEWED FROM REAR-

STEAM HEATED

MACHINES ONLY)

Loading...

Loading...