41

English

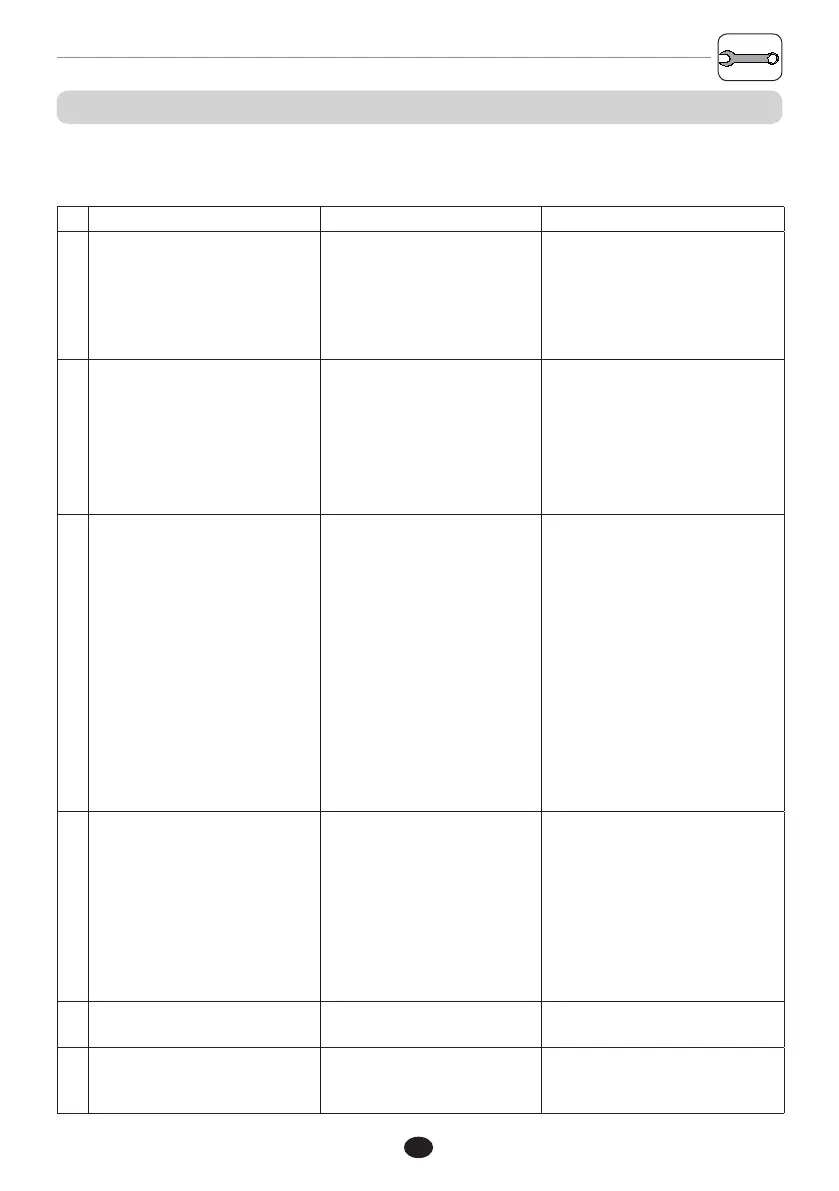

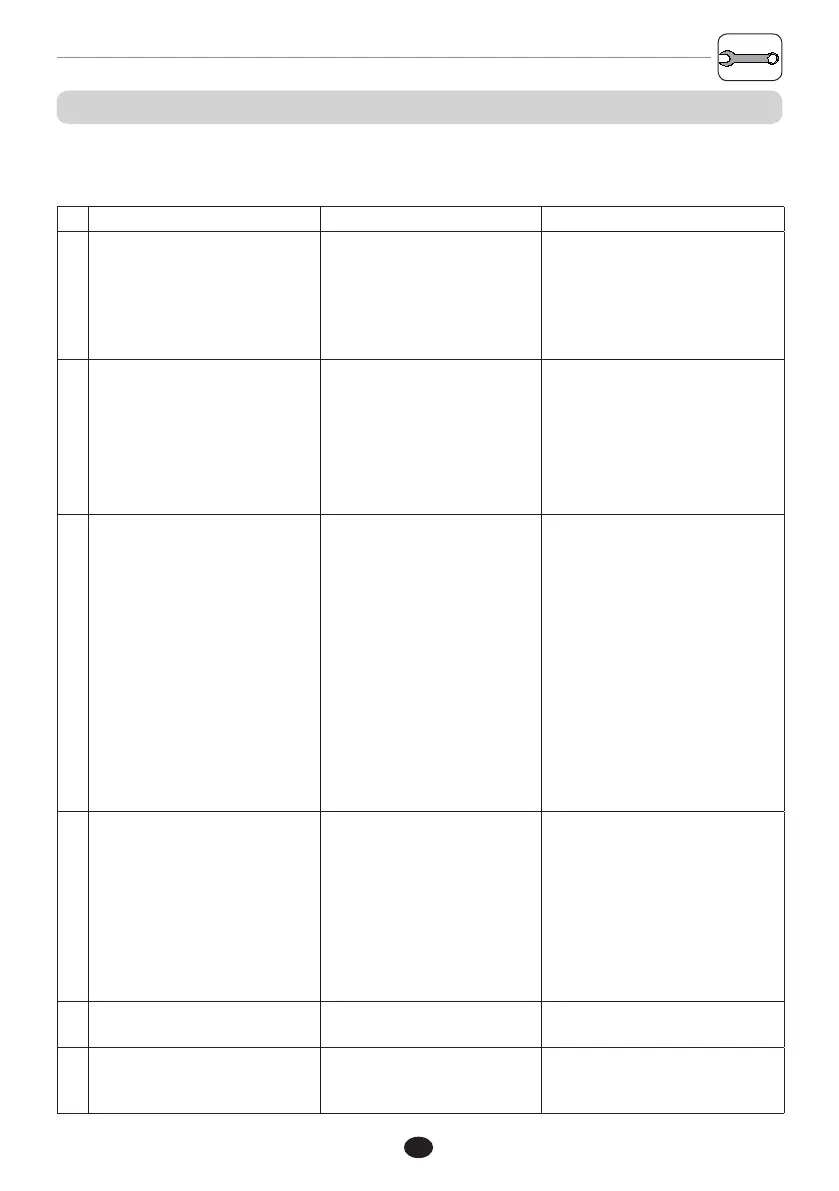

PROBLEMS:

Below is a list of the solutions for some problems that may occur on the machine

over time.

9 - MAINTENANCE AND REPAIR

ANOMALIES CAUSES SOLUTIONS

1

WHEN THE MAIN SWITCH

IS TURNED O N THE DIFFE-

RENTIAL BLOWS

- Differential too weak - Compare the machine data

with the data of the instal-

led differential

- Extension cable excessi-

vely long

- Use a suitable extension ca-

ble

- Resistance insulated - Replace resistance

2

THE GENERATOR PRESSURE

DOES NOT INCREASE

- Machine with lack of

water

- Check water quantity in

tanks

- Pressure gauge - Check pressure gauge

- Resistance - Check resistance

- Thermoregulator - Check that the temperatu-

re is at least 150°C

- Fuses cut out - Check fuses

3

PUMP DOES NOT WORK

- Water tanks empty - Fill up tanks

- does not load water - Pump - Replace pump

- Filter clogged - Celan or replace f lter

- Water lacking pilot light is

always on

- Pump - Replace pump

- Lack of water in tank - Fill up tank

- Water electrovalve - Replace electrovalve

- Level regulator - Check conductivity of level

regulator

- does not starts - Level probe - Remove any scaling or al-

gae from probe

- Level regulator - Check operation of level re-

gulator

4

SAFETY VALVE OPENS RE-

PEATEDLY

- water is loaded continuo-

usly

- Boiler water level probe - Remove any scaling or al-

gae from probe

- Check operation of level re-

gulator

- Level regulator

- Pressure switch - Replace pressure switch

and check that the hydrau-

lic circuit is free from sca-

ling

- Safety valve - Replace safety valve

5

STEAM IS NOT SUPPLIED

- Electrovalve coil cut off - Replace coil

- Electrovalve body dirty - Replace electrovalve body

6

VERY HOT SURFACE

- Internal steam leak - repair leak

- fans do not work - replace fans or check

electric system

Loading...

Loading...