Section 5 - Maintenance

Page 78 90-899883173 DECEMBER 2007

5. Use a 8 mm (5/16 in.) socket and tighten adjusting the stud to adjust the belt deflection.

6. Using one of the 2 methods following, check for correct deflection.

a. Push down with moderate thumb pressure on the longest stretch of belt. Proper

deflection is 13 mm (1/2 in.).

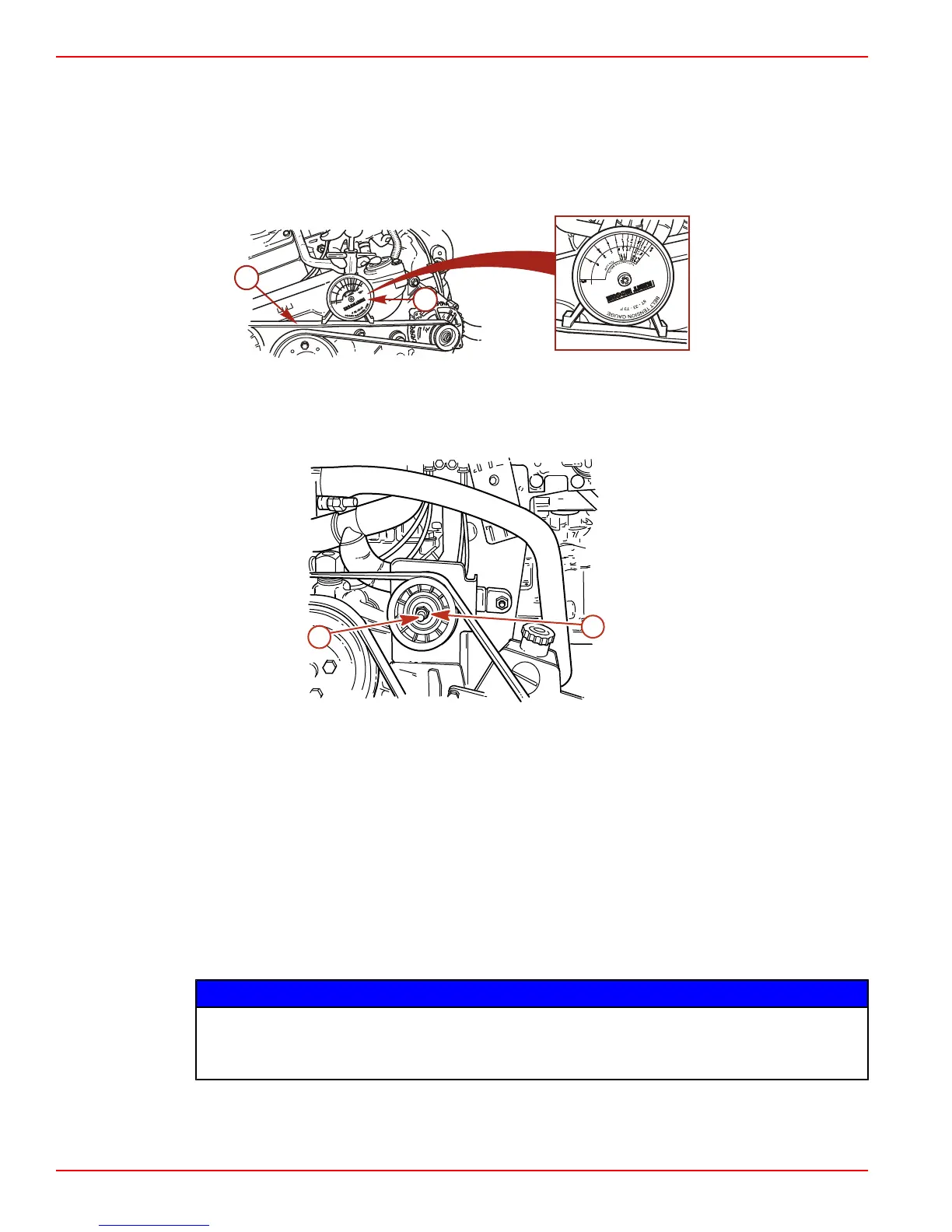

b. Attach the Kent Moore© Belt Tension Gauge to the belt. The gauge has different

ranges for new and used belts.

COLOR GUIDE

for

PATENT

2.83918

NEWTONE

NEWTONE

b

a

14980

a - Kent Moore© Tension Gauge b - Serpentine belt

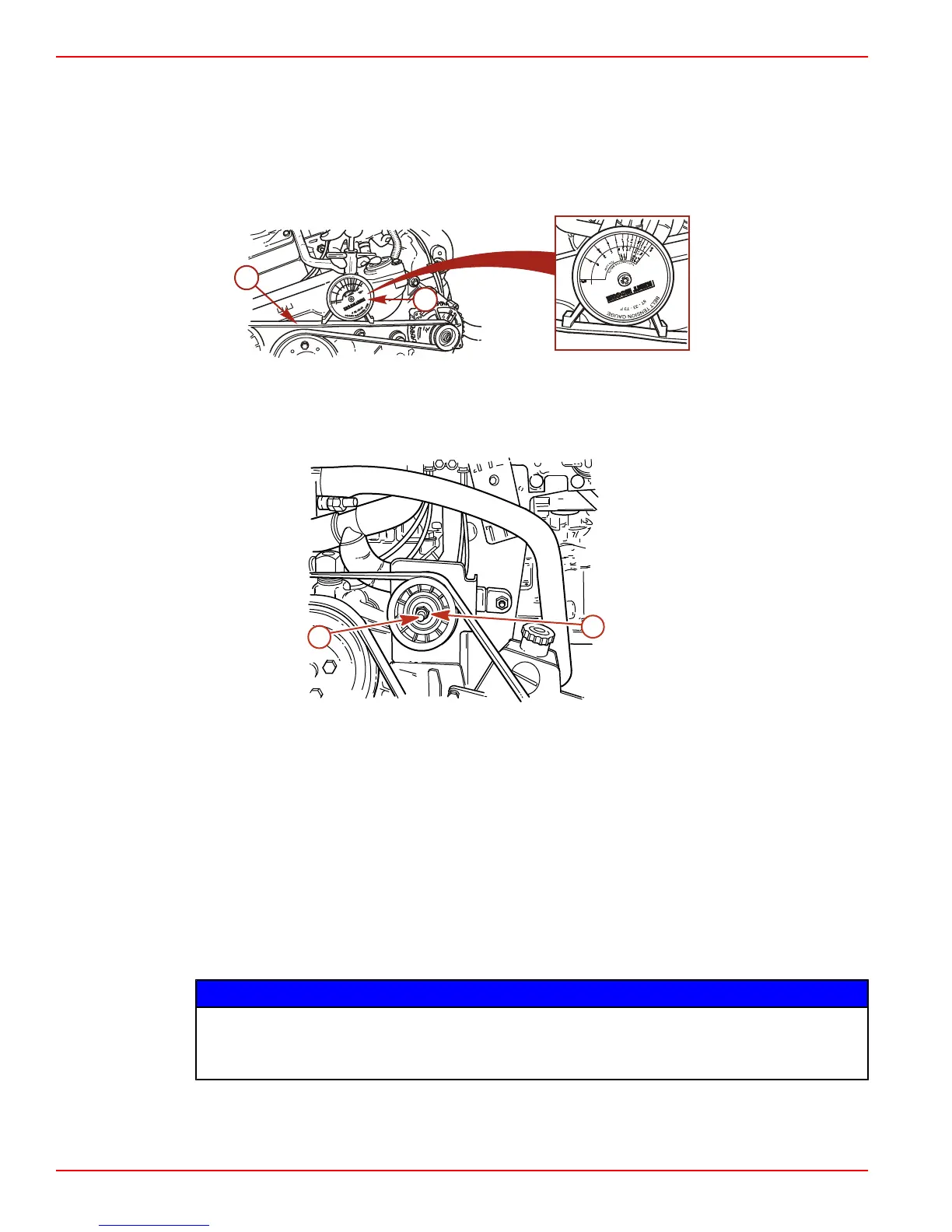

7. While holding the adjustment stud at the correct belt tension, tighten the 16 mm

(5/8 in.) locking nut.

a

b

6119

a - 8 mm (1/16 in.) adjusting stud

b - 16 mm (5/8 in.) locking nut

8. Operate the engine for a short period of time and recheck the belt adjustment.

Flushing The Power Package

Horizon Models

NOTE: Flushing is needed only for salty, brackish, mineral laden or polluted water

applications. Flushing is recommended after each outing for best results.

1. Close the seacock, if equipped, or remove the water inlet hose and plug the inlet.

2. Attach the quick connect fitting to a water hose.

3. Remove the blue cap from the flush socket on the engine

NOTICE

Without sufficient cooling water, the engine, the water pump, and other components will

overheat and suffer damage. Provide a sufficient supply of water to the water inlets during

operation.

Loading...

Loading...