6 BC 71 en 3

1 GENERAL

1.1 Scope of the manual

These instructions provide essential information for the use

of Metso B1C series actuators. For more details about

valves, positioners and accessories, refer to the separate

installation, operating and maintenance instructions of the

particular unit.

1.2 Structure and operation

The B1C series actuators are pneumatic cylinder actuators

designed for control and shut-off service.

The linkage bearings have material options. The robust

cast-iron housing efficiently protects the mechanism from

ambient dust and moisture.

The mounting face dimensions of the B1C actuator comply

with the ISO 5211 standard.

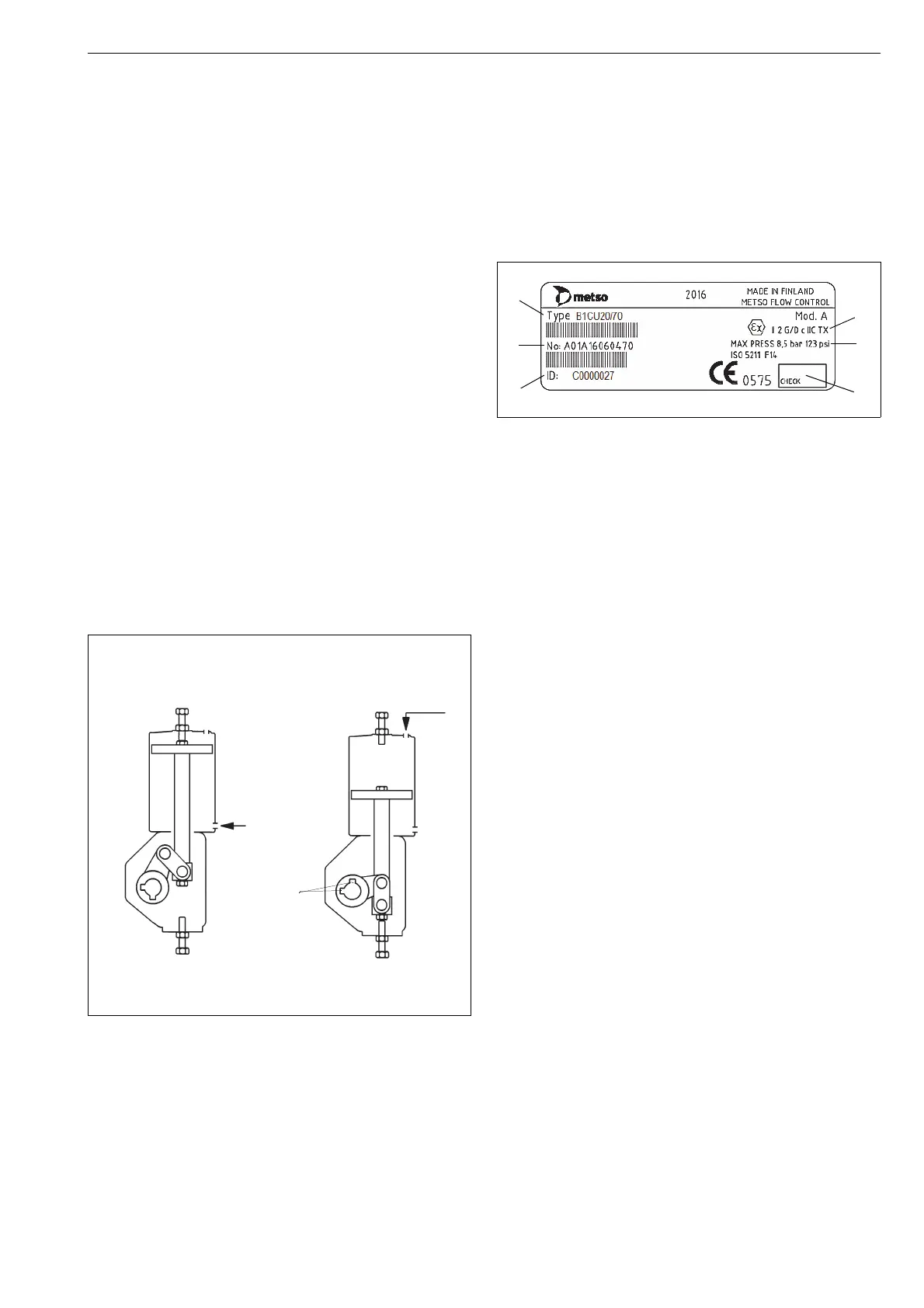

The linkage converts the linear motion of the piston into

rotation by the actuator shaft. The actuator generates maxi-

mum torque when for example a ball or butterfly valve is

closed, and the need for torque is greatest. Another peak is

achieved at 60-80°, when the need for torque on a butterfly

valve caused by the dynamic forces of for example pipe

flows reaches a maximum.

Screws are located in the upper end of the cylinder and in

the lower end of the housing to regulate the length of the

piston stroke and also the rotation angle of the actuator

shaft.

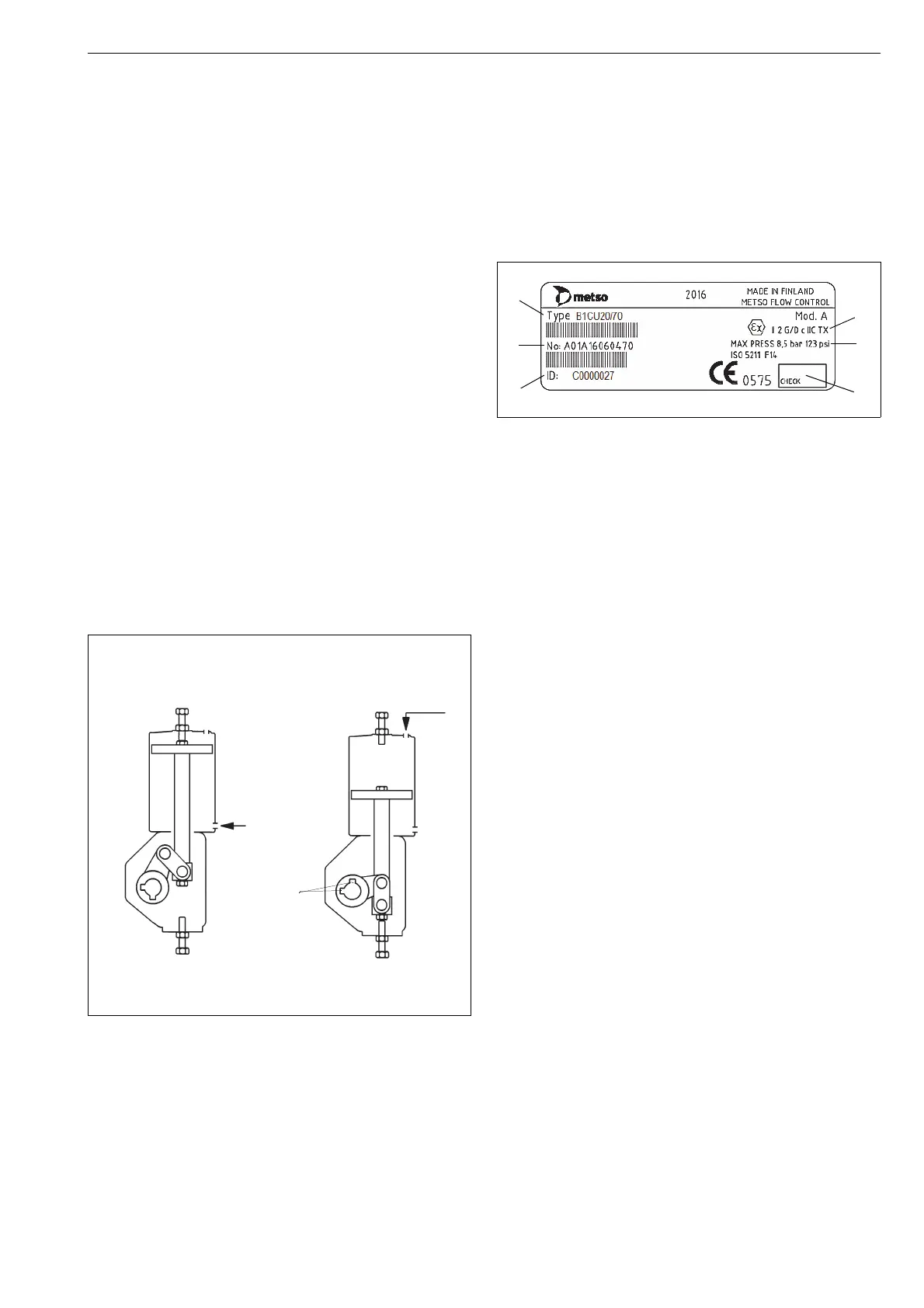

1.3 Actuator markings

The actuator is provided with an identification plate, see

Fig. 2. Identification plate markings are:

1. Type

2. Manufacturing site, date, successive no. (bar code)

3. SO number or ID number (bar code)

4. Checked by

5. Max. supply pressure

6. ATEX category and protection level

1.4 Specifications

Protection class: IP66, NEMA 4X

Ambient temperatures:

Standard design -20° to 70 °C / -4° to 160 °F

Low temperature design -40° to 70 °C / -40° to 160 °F

High temperature design -20° to +120 °C / -4° to 250 °F

Arctic temperature design -55° to +70 °C / -67° to 158 °F

Maximum supply pressure:

B1C 6...17, 60, 602 8.5 bar / 120 psi

B1C 20...50, 502 10 bar / 145 psi

B1C 75, 752 5 bar / 70 psi

Stroke volume, dm

3

/ in

3

B1C 6 0.33 / 20

B1C 9 0.60 / 37

B1C 11 1.10 / 67

B1C 13 2.30 / 140

B1C 17 4.30 / 262

B1C 20 5.40 / 329

B1C 25 10.50 / 640

B1C 32 21 / 1280

B1C 40 43 / 2620

B1C 50 84 / 5130

B1C 60 121 / 7380

B1C 75 189 / 11500

B1C 502 195 / 11900

B1C 602 282 / 17200

B1C752 441 / 26900

Fig. 1 Operating principle of the actuator

VALVE OPENVALVE CLOSED

opening

2 keyways

pressure

closing

pressure

Fig. 2 ID plate.

Loading...

Loading...