Do you have a question about the Metso Jamesbury 7150 Series and is the answer not in the manual?

Defines the manual's scope and details valve identification markings.

Outlines critical safety warnings and precautions for handling and operating the valves.

Covers initial steps like cleaning, flushing, and fitting the valve into the pipeline.

Explains requirements and limitations for insulating the flanged ball valves.

Guidance on actuator installation and final steps before operation.

Overview of preventative maintenance, routine tasks, and steps for disassembling bare stem valves.

Specific procedures and tools for disassembling Emission-Pak configured ball valves.

Guidance on inspecting components and reassembling bare stem and Emission-Pak valves.

Procedures and warnings for performing pressure and tightness tests on the valves.

Steps for correctly attaching handles and installing stem extensions for operation.

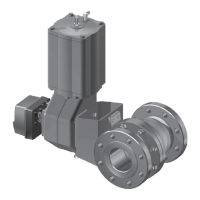

Overview, valve preparation, and bracket preparation for actuator mounting.

Procedures for attaching the bracket, coupling, and ensuring correct valve/actuator position.

Procedures for adjusting actuator travel stops for correct valve open/close positions.

Instructions on how to use tables to identify the correct repair kit based on valve catalog code.

| Type | Control Unit |

|---|---|

| Series | 7150 |

| Manufacturer | Metso Jamesbury |

| Actuator Type | Pneumatic |

| Pressure Rating | Up to 1500 psi |

| Materials | Stainless Steel, Carbon Steel |

Loading...

Loading...