Do you have a question about the Metso Finetrol and is the answer not in the manual?

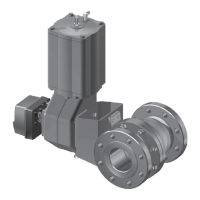

Provides essential information for users of Finetrol eccentric rotary plug control valves.

Describes the Finetrol eccentric rotary plug control valve's design and one-piece body.

Explains the identification plate and markings on the valve for identification.

Details face-to-face length, body rating, pressure differential, and temperature ranges.

Outlines valve design standards and approvals like API 607 and BS 6775.

Explains compliance with the European Directive 2014/68/EU for pressure equipment.

Provides guidance on material recycling, disposal, and manufacturer return options.

Crucial safety warnings about valve performance, pressure, plug movement, and noise.

Instructions for removing port protectors and checking the valve for damage.

Guidance on pipeline preparation, flange gasket selection, and alignment.

Guidance on installing the actuator and aligning the plug position.

Steps for final checks, pipeline flushing, and actuator adjustments.

General recommendations for valve inspection and maintenance intervals.

Procedures for cleaning and freeing a jammed or stuck valve.

Step-by-step guide for replacing valve packing to prevent leakage.

Procedures for safely removing the actuator from the valve.

Steps for safely detaching the valve from the pipeline.

Instructions for replacing the valve seat to ensure tightness.

Step-by-step guide for complete valve disassembly.

Guidance on cleaning, inspecting, and replacing removed valve components.

Procedures for reassembling the valve after maintenance or parts replacement.

Details constructional differences for FL low capacity valves.

Overview of Metso actuators that can be mounted on the valve.

Detailed instructions for installing Quadra-Powr actuators.

Instructions for installing B1C series actuators with safety warnings.

Instructions for installing B1J and B1JA spring-return actuators.

Procedures for detaching B series actuators.

Instructions for installing EC and EJ actuators with bushings.

Procedures for detaching EC and EJ actuators.

Adjusting open/closed limits for FL low Cy valves.

Guidelines for installing actuators from other manufacturers.

Exploded view and parts list for the Finetrol FC series valve.

Exploded view and parts list for the Finetrol FL series valve.

Dimensional data for Quadra-Powr actuators with various valve sizes.

Dimensional data for B1C/B1J actuators with various valve sizes.

Dimensional data for EC actuators with various valve sizes.

Dimensional data for EJ actuators with various valve sizes.

| Category | Control Unit |

|---|---|

| Manufacturer | Metso |

| Input Voltage | 24 VDC |

| Output Current | 4-20 mA |

| Communication Protocol | HART |