Do you have a question about the Metso Mapag BAR Series and is the answer not in the manual?

Critical safety warnings and precautions for handling and operating the valve.

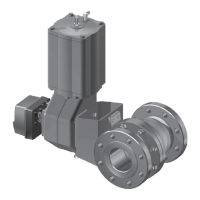

Details on valve types, sizes, temperature ranges, and operational principles.

Specifies the intended applications and operating parameters for the valve.

Lists the components included in the valve delivery and their packaging.

Procedures for inspecting the valve for shipping damage and verifying its function before installation.

Explains the identification plate and markings on the valve for reference.

Information regarding ATEX and CE compliance markings on the valve.

Provides contact information for Metso partners and support.

Key considerations before commencing the valve installation process.

Preparatory steps and checks required before valve assembly.

Step-by-step guide for physically installing the valve into the pipeline.

Specific requirements for ATEX-certified valves, including grounding.

Important general safety and handling notes for actuator work.

Steps to prepare for mounting or detaching the actuator, including weight considerations.

Detailed instructions for mounting the actuator onto the valve.

Checks to perform before detaching the actuator from the valve.

Step-by-step process for removing the actuator from the valve.

Detailed dimensions and weights for the BAR_3_ valve type.

Detailed dimensions and weights for the BAR_6_ valve type.

Detailed dimensions and weights for the BAR_4_ valve type.

Guidelines for cleaning and recommended intervals for maintenance tasks.

Recommendations for preventative maintenance schedules and component replacement.

Prerequisites and considerations before performing maintenance.

Step-by-step instructions for disassembling the valve.

Step-by-step instructions for reassembling the valve.

Detailed procedure for replacing the valve's sealing element.

Table detailing maximum closing torques for valves under specific conditions.

Procedures for identifying and replacing common wearing components of the valve.

Description and functional overview of the O-ring design for the BA valve.

Guidelines for cleaning and recommended intervals for maintenance tasks.

Visual representation and list of valve components for identification and ordering.

Recommendations for testing prestressing force of disc springs in gland packing.

| Brand | Metso |

|---|---|

| Model | Mapag BAR Series |

| Category | Control Unit |

| Language | English |