16 2 BAR 70 en

If you do not make the disassembly by yourself, instruct the

qualified personnel and provide them with protective

clothing, if necessary.

While assembling and disassembling the on/off (butterfly)

valve, the on/off (butterfly) valve must be closed to exclude

any incidental damage.

10.4 Disassembly

Ensure that:

□ The pipeline is pressureless and cleaned well.

□ The relevant valve is disengaged from the process.

□ The valve is in a defined position – “closed” in general.

Caution – Danger of explosion! It is mandatory to follow

the safety instructions of the operator!

Proceed in the following sequence for dismantling the

on/ off (butterfly) valve:

□ Close the on/off (butterfly) valve.

□ If the actuator must be removed for dismantling the on/

off (butterfly) valve, mark its direction to the bracket and

the body with a waterproof felt-tip pen before disman-

tling the actuator. (see Figure 16). In this manner you

can correctly reposition the drive during reinstallation

and prevent it from triggering any faulty function.

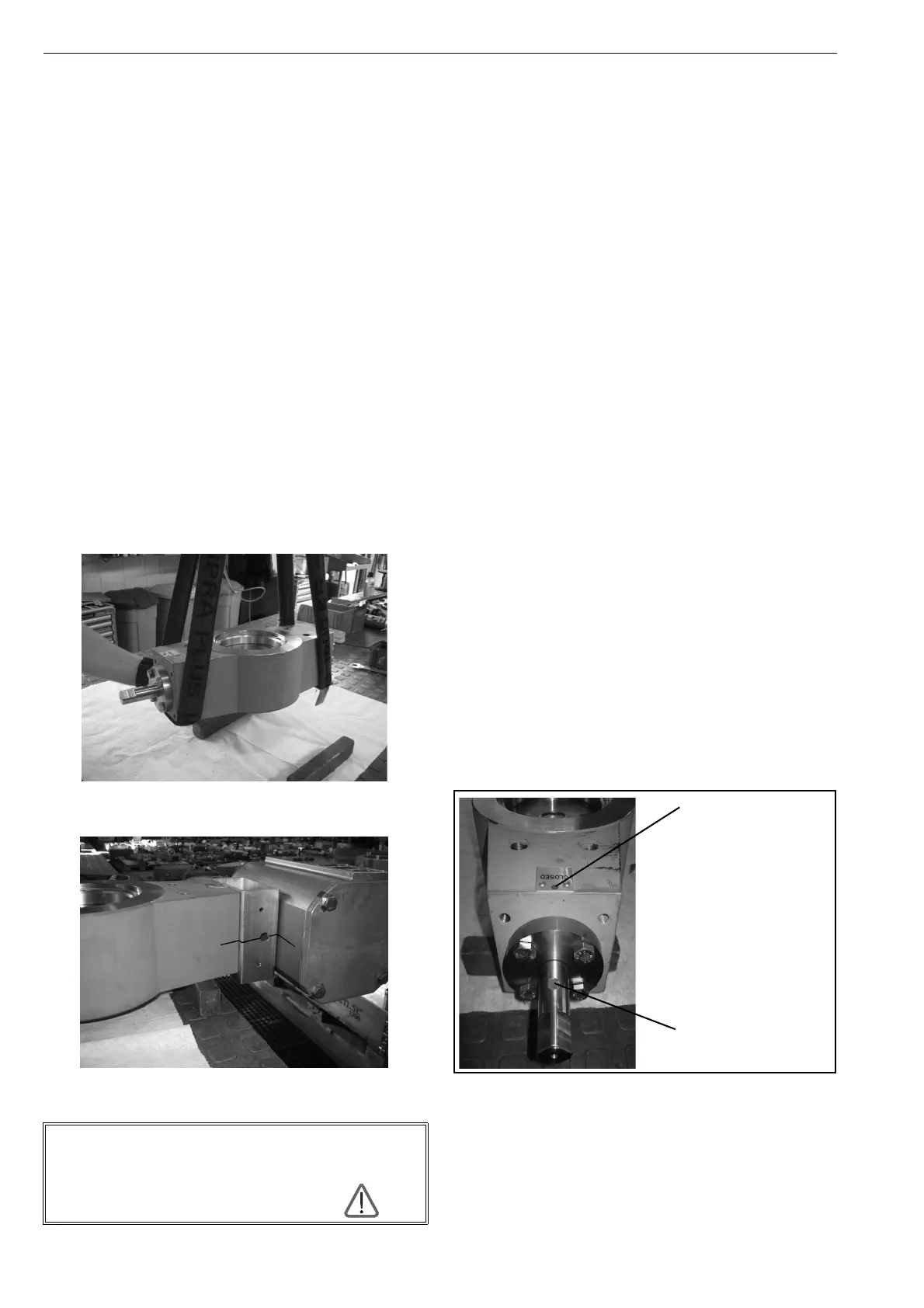

Figure 15 Securing using lifting ropes

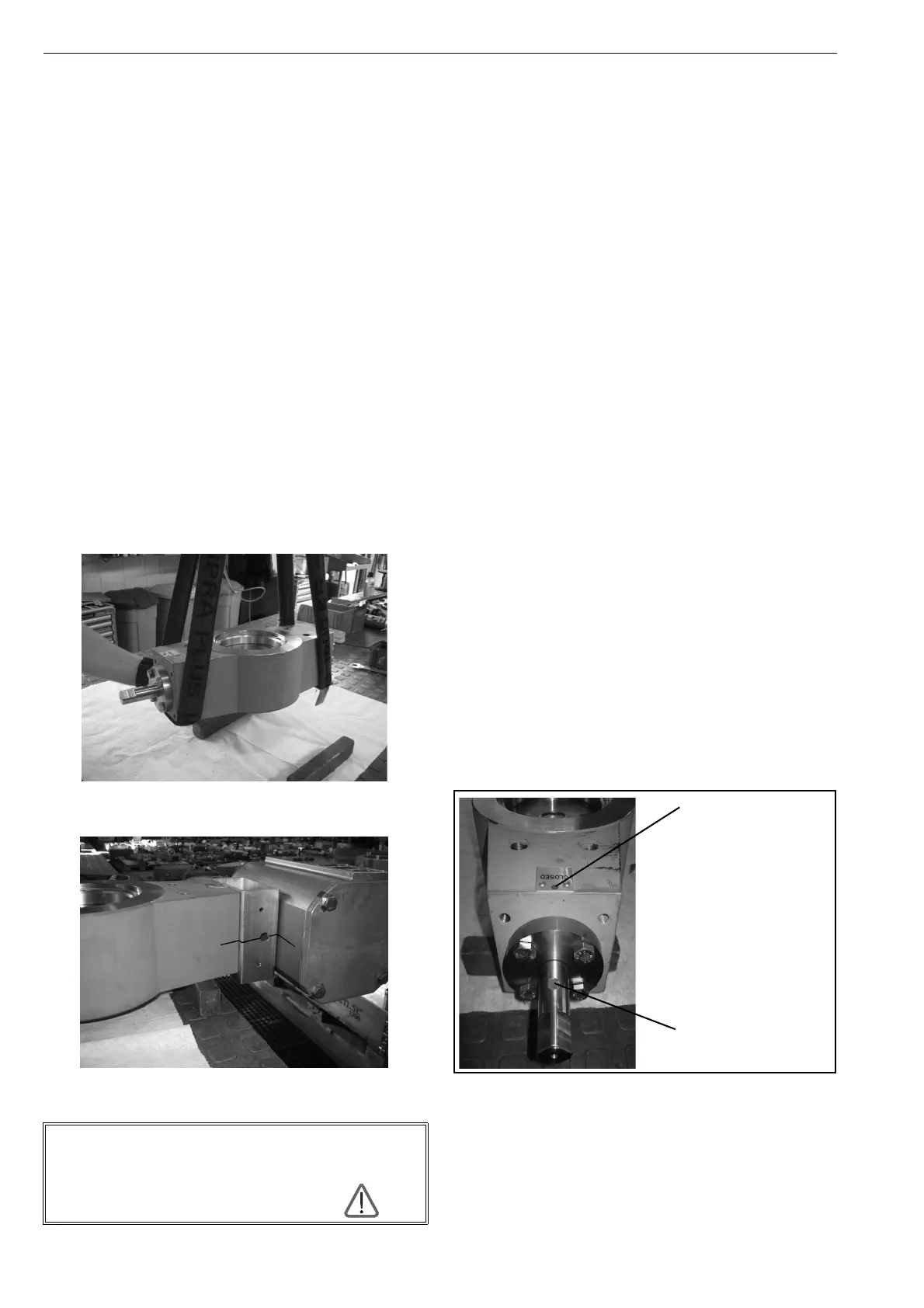

Figure 16 Marking of the actuator position

Dismantle the actuator. Refer to point 4.5 of the IMO for this

□ Secure the on/off (butterfly) valve using lifting ropes. Do

not bring the lifting ropes close to the body (and the

shaft) of the on/off (butterfly) valve. (see Figure 15).

□ Release the on/off (butterfly) valve by loosening the

screws opposite to one another or the nuts in a cross-

wise manner.

□ Transport the on/off (butterfly) valve securely, so that

they do not move during transport and eventually get

damaged.

10.5 Reassembly

Proceed as follows for reassembling the on/off (butterfly)

valve:

□ Close the on/off (butterfly) valve.

□ A round marking is at the end of the drive shaft and on

the body of the on/off (butterfly) valve respectively. The

round marking on the drive shaft should point in the

direction of the round marking on the body during rein-

stallation (see figure 17).

□ Bring the actuator to the “closed” position.

□ Ensure that you set the actuator in the correct position

on the drive shaft. Use the marking that you made on

the bracket and the actuator while dismantling the on/

off (butterfly) valve, and pay attention to most accurate

alignment of the marking on all components (body–

bridge – drive) See figure 16 Marking of the actuator

position.

□ Install the on/off (butterfly) valve between the pipelines

(see chapter 4.3 and following)

10.6 Replacement of the sealing element

If you want to change the sealing element at the high-per-

formance valve, then please proceed as follows (see

Figure 17):

Figure 17 Replacing the sealing element

1. Dismantle the valve in 0°-position (closed) (see

figure 18). Instructions for disassembly can be found

from chapter 4.5 of the IMO.

2. Fix the valve in a slip and tilt-proof manner on a stable

base or workbench.

Disconnect the energy supply to the actuator. In

addition, press the EMERGENCY STOP switch for

energy supply to the actuator or activate the remote

control, so that no one can reconnect

the energy supply by mistake.

Marking on the body

Marking on the drive shaft

Loading...

Loading...