2 BAR 70 en 9

4 Detaching and mounting the actuator

of type F1A/F1F

4.1 General

4.2 Mounting preparation

Lifting gear is required for installing larger actuators in situ.

The actuator type and size are indicated on the identifica-

tion plate (Figure 9 Identification plate of the actautor).

The weight of the actuator is specified in the following

table.

Figure 9 Identification plate of the actuator of drive

Figure 10 The marking on the selector shaft corresponds to

the position of the on/off disc

Figure 11 Checking the closed position by means of depth

measurements

4.3 Mounting

Proceed as follows for installing the actuator:

□ Before attaching the actuator, set the valve in the closed

position.

□ Push the selector shaft of the actuator carefully onto the

valve shaft. Note that the actuator adjoins the bracket

exactly and is aligned with it, so that no stresses may

occur at the valve shaft.

□ Note that the marking on the drive shaft corresponds to

the position of the on/off disc (see Figure 10).

□ Secure the actuator to the bridge using the four screws

and tighten them on their cross tips. Information: The

housing of F1 -series actuator are composed of an alu-

minum material. The fastening threads may be dam-

aged by uncontrolled tightening.

→ Refer to 12.8 for

torque values

□ Now finally check the closed position of the valve once

again by means of several depth measurements,

wherein the determined data may vary from one

another by a max. of 0.3 mm (see Figure 11).

□ Finally connect the energy supply (see figure 12).

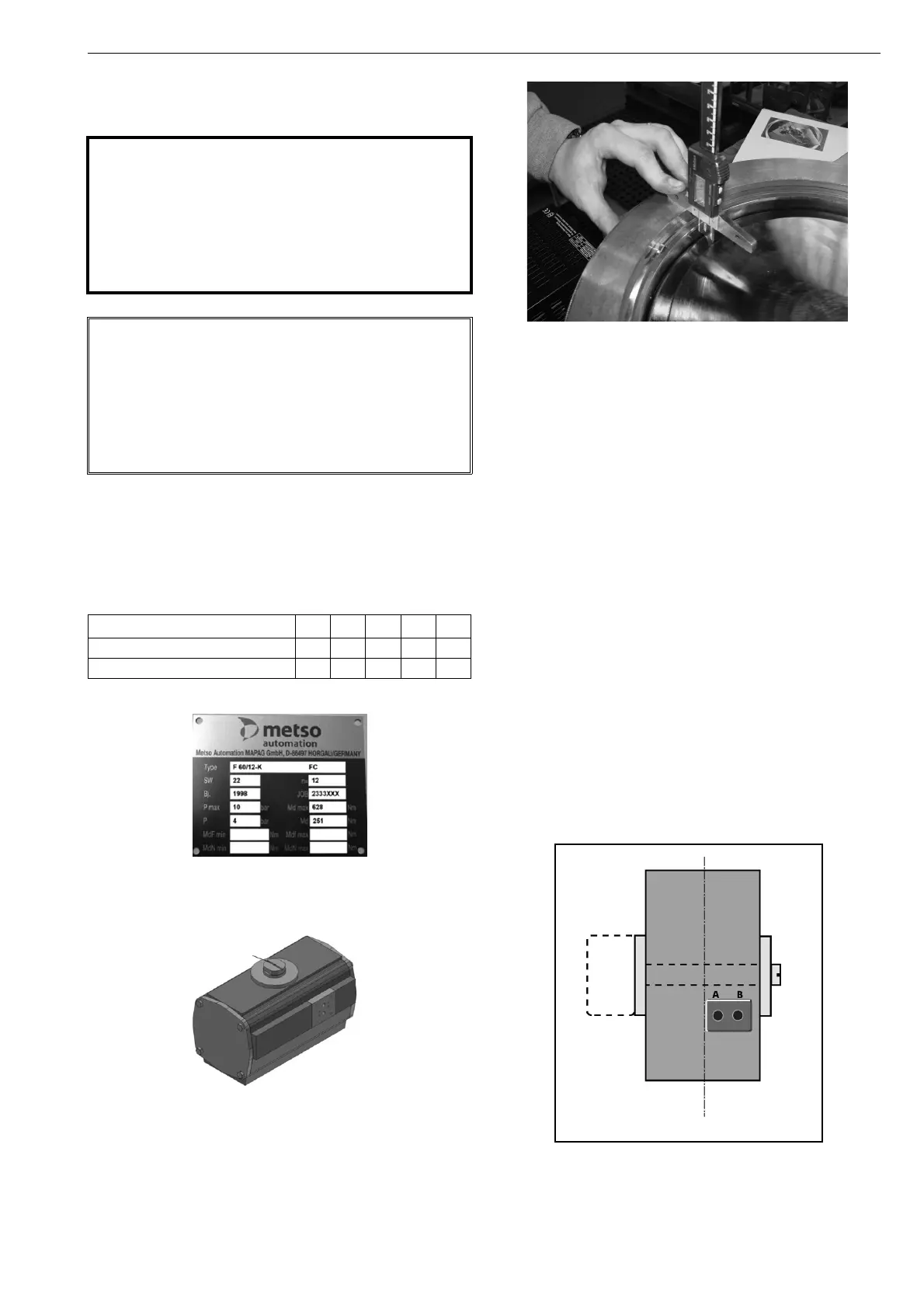

Figure 12 Connecting the pneumatics

CAUTION:

Note the weight of the valve or the entire servo unit

while handling!

The actuator may not be detached from the valve if

the pipeline is under pressure as a consequence of a

dynamic torque!

Do not dismantle any actuator with spring retainer

without securing the spring with a stop screw!

NOTE:

Before dismantling the actuator, note the mounting

position and opening angle of the valve with respect to

actuator and positioner/ limit switch so that the correct

function is maintained in the following assembly.

You must install the actuator, so as to allow free access to

it any time. This especially applies also to a possible

“emergency stop” operation by hand.

actuator size 30 60 120 250 500

double-acting type F1A [kg] 10 16 28 51 100

single-acting type F1F [kg] 13 21 56 85 160

Mounting

bracket

A = Air open

B = Air close

Loading...

Loading...