2 BAR 70 en 5

The valves data are shown on the identification plate

attached to the body.

In the service case, the factory number (unique no.) is the

one that uniquely designates the valve. This number is also

attached to the body in case the identification plate can no

longer be found.

Further information:

Job no. = job number at Metso Automation

MAPAG

Type = Type code of the valve

body = body material

YEAR = Year of manufacture

NPS or DN = Size; CL or PN = pressure class

Pressure class

ID no. = Customer identification number

Tag no. = Valve and fittings number

TS. = Operating temperature of the

valve in °C (medium)

PS = Operating pressure of the valve

P.O.NO. = Order number of the customer /

consignment number

CV = Flow rate in gallons/min

EX II 2GcTx = Atex sign

CE = CE0036 (notified body for PED)

The following markings are made (see Figure 4) for display-

ing the disc position in the installed valve:

□ CLOSED sign with colored marking on the body.

□ Colored marking on the valve shaft.

If both red markings are (align axially), the valve position is

"closed". The sealing element is on the side of the body on

which the “Closed” sign is mounted.

1.7 ATEX and CE -marking

The valve fulfills the requirements of the European Directive

97/23/EC regarding pressure-related equipment and is

marked according to this directive.

The ATEX and CE signs are displayed on the identification

plate (see Figure 3 Rating plate).

1.8 Contact

Please contact your local Metso partner.

You will find the contact information at:

www.metso.com/automation

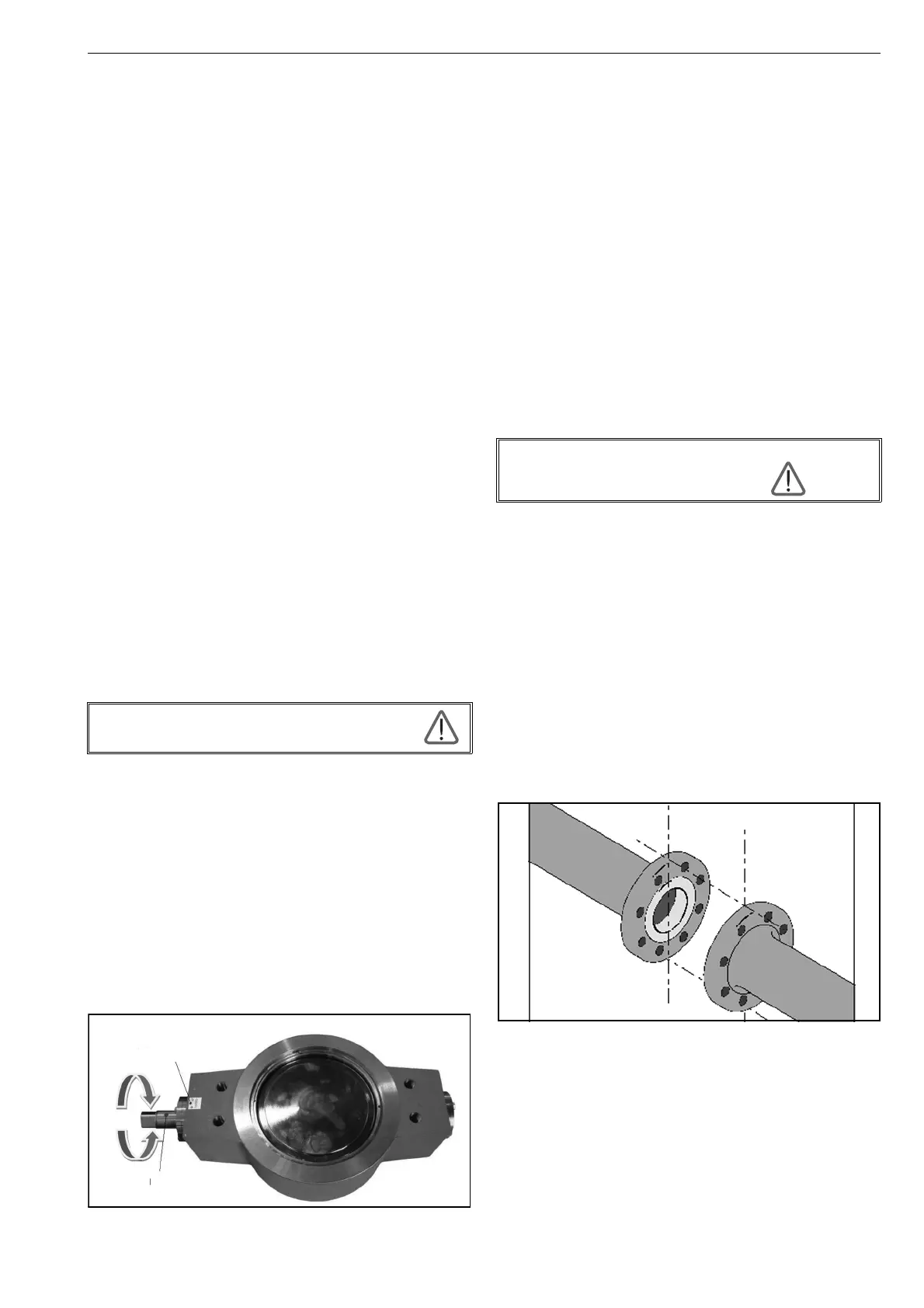

Figure 4 Direction of the actuator and position of the on/

off disc.

2 Transport, reception and storage

Check the valve including accessories for shipping damage.

Prior to installation, the valve is to be carefully stored in a

dry roofed room.

Storage temperature = -20° to 80 °C

Relative humidity 85% max. (non-condensing)

The valve must be warehoused with the factory-mounted

covers.

The valve should be transported on-site only a short while

before the installation.

The covers on the openings are to be removed for installing

the valve.

The valve is delivered in closed position.

A valve with an actuator and a spring retainer is delivered in

the position set by the spring (spring opens or closes).

3 Installation

3.1 Installation planning

Consider following aspects before assembly:

□ You must install the on/off (butterfly) valve, so as to

allow free access to the drive at any time.

□ Drives that are operated using electric, pneumatic or

hydraulic energy may be connected to the energy sup-

ply only after installing the on/off (butterfly) valve.

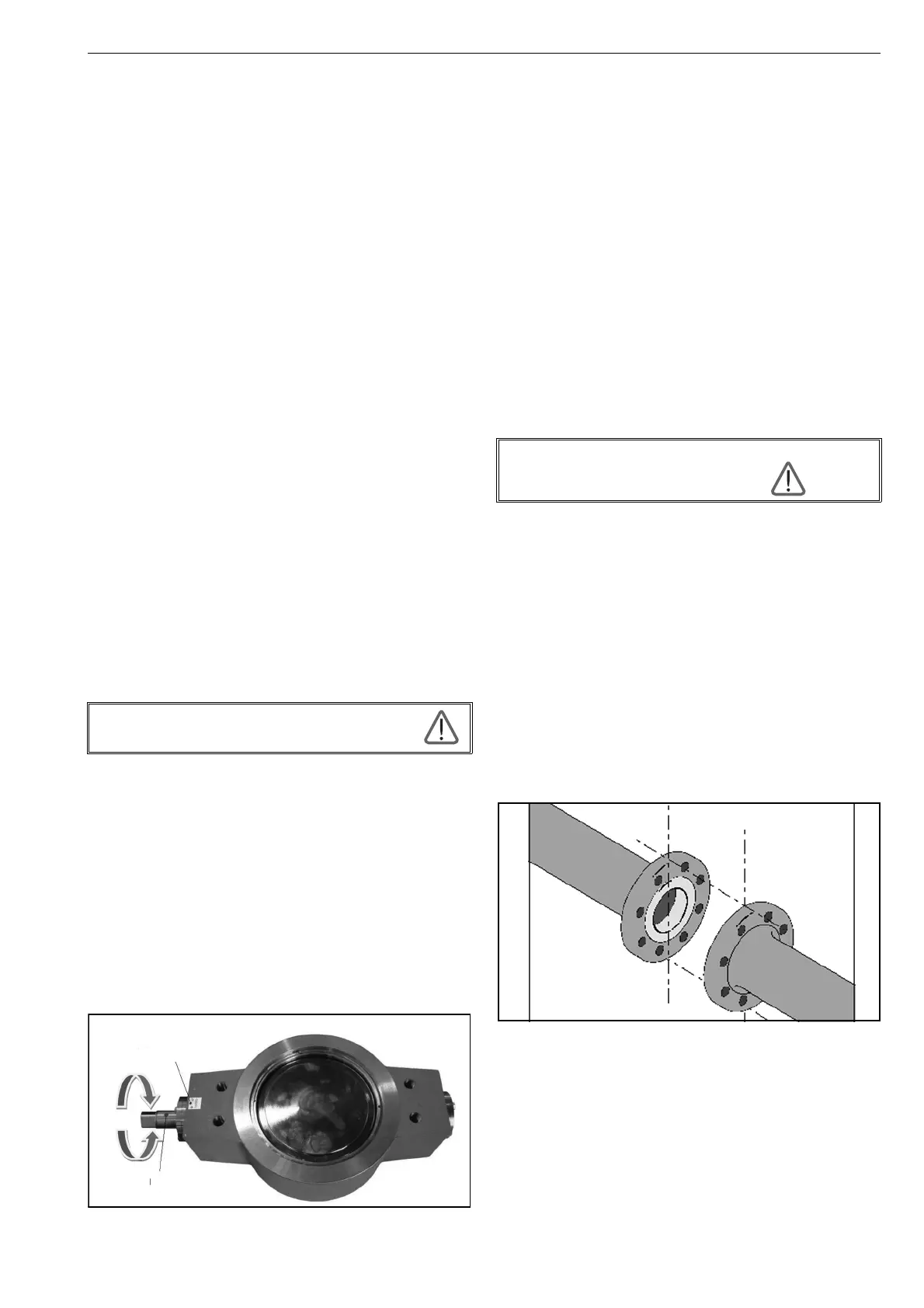

□ The flange holes of both pipeline ends must be exactly

aligned axially with each other, the sealing surfaces of

the opposite flanges must be parallel to each other. The

flange holes may not be distorted from one another, so

that the on/off (butterfly) valve is not exposed to any

stresses during assembly.

Figure 5 Alignment of the flanged pipes

Opening and closing similar to a water tap.

(viewed from the actuator side)

Close in

clockwise

direction

Open

counterclock-

wise direction

Marking drive shaft

Marking on the body

Assembly work at the on/off (butterfly)

valve shall be made only by

qualified personnel!

Loading...

Loading...