2 BAR 70 en 15

9 Safety instructions

Please follow the below-mentioned safety instructions dur-

ing installation, maintenance and operation of the high-

performance valve:

1. For safety reasons, you may not do any modifications to

the mode of operation of the high-performance valve

or its actuator.

2. Assembly work at the high-performance valve must be

done only by qualified personnel!

3. A functional test is associated with the risk of sudden

uncontrolled movement of the high-performance valve

upon supply of energy. Therefore, ensure that the valve

does not move or tip over during the functional test

under any circumstances.

4. Exercise caution while installing valves in the failsafe

position "spring opens" If the on/off disc extends beyond

the installation length of the valve, then the on/off (but-

terfly) valve must be closed before installation (pneu-

matic, hydraulic etc.). It is mandatory to ensure that the

energy supply lines are secured and not damaged or

ruptured during installation under any circumstances.

If the energy supply is interrupted suddenly, the valve

opens abruptly. This can lead to serious injury and to

material damage.

5. There is a significant risk of injury from accidental oper-

ation of the remote control during any maintenance

work. If you intend to use a remote control for working

with the high-performance valve, then an additional

emergency stop switch that acts as a locking device is

required at the actuator.

6. Make sure that cleaning agents do not cause any

unwanted chemical reactions upon contact with possi-

ble residues in the high-performance valve.

7. While working in the area of the sealing surface of the

on/off disc, secure the on/off disc using wooden

wedges to exclude crushing hazard. Pay attention to

the fact that you do not damage the sealing surface of

the on/off disc as a result.

8. If the seals are destroyed by an excessively hot medium,

the used medium can escape at the shafts.

10 Maintenance

10.1 Cleaning and maintenance intervals

High-performance valves of the type BAR are mostly main-

tenance-free.

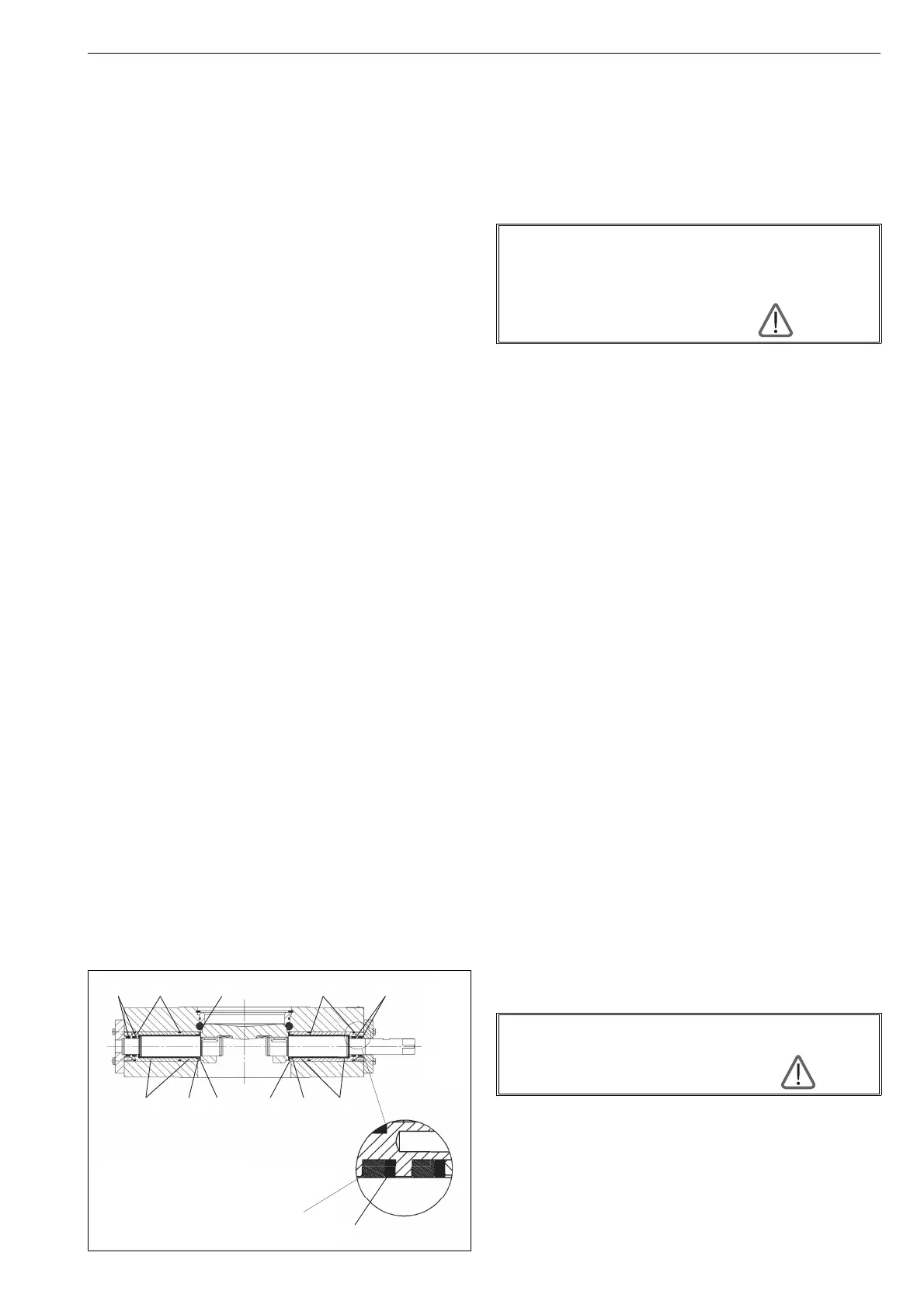

Figure 14 Seals and bushes

If the medium carries along contamination with itself that

may impair the seal-tightness of the valve, then the sealing

surface of the on/off disc must be cleaned regularly. Con-

tamination may damage the sealing surface of the on/off

disc or the sealing element.

Auxiliaries that may attack the sealing surface or the elastomer

seal may never be used for removing residues. Use water,

soapsuds or other liquid solvents and a soft, lint-free rag.

At the same time also check the condition of retainer rings

(419, 471), the support rings (406), the shaft seal ring (429,

475) and the bearings (424) (see Figure 14 seals and

bushes).

While assigning cleaning and maintenance work to quali-

fied external firms and / or qualified external personnel, it is

mandatory to make them aware of the dangers of the used

medium and possibly present residues. The IMO is handed

over.

10.2 Preventive maintenance recommendation

1. For operating pressures of CL300/ PN40 and below:

A) Spare set ”Seat” and ”Shaft Sealing” to be replaced latest

at 750.000 cycles or 3 years operations.

B) Spare set ”Complete” to be replaced latest 1.500.000

cycles or 6 years operations.

2. For pressure class CL600 / PN64:

A) Spare set ”Seat” and ”Shaft Sealing” to be replaced latest

400.000 cycles or 2 years operations.

B) Spare set ”Complete” to be replaced latest 800.000 cycles

or 4 years operations.

3) This recommendation applies to both control as well

as on-off valves

10.3 Preliminary

Suitable spare parts sets should be kept ready and / or pro-

vided on time to avoid longer downtimes during mainte-

nance work. Please take into account the delivery and

transport times.

Before dismantling the on/off (butterfly) valve, the follow-

ing prerequisites must be met:

□ Ensure that the pipelines are pressureless and free of

process-related gases and fluids.

□ Inform yourself about the medium that last passed

through the on/off (butterfly) valve. Residues may occur

in the valve. Make sure that there is no poisoning or

acid-burn risk when coming in contact with the resi-

dues. Protect yourself using appropriate protective

clothing, safety goggles and a breathing mask, where

appropriate. It is mandatory to follow the safety instruc-

tions for operating personnel.

471 419 320 419 471

424 475 429 429 475 424

471

406

Never use cutting, scraping or grinding tools such as

files or sandpaper. Moreover, do not use any solvent-

based cleaning agents that may cause unwanted

chemical reactions upon contact with residues of the

medium or attack

the seal.

Check whether the on/off (butterfly) valve has

already cooled down or warmed up to the extent that

there are no more hazards due to

extreme temperatures.

Loading...

Loading...