18 2 BAR 70 en

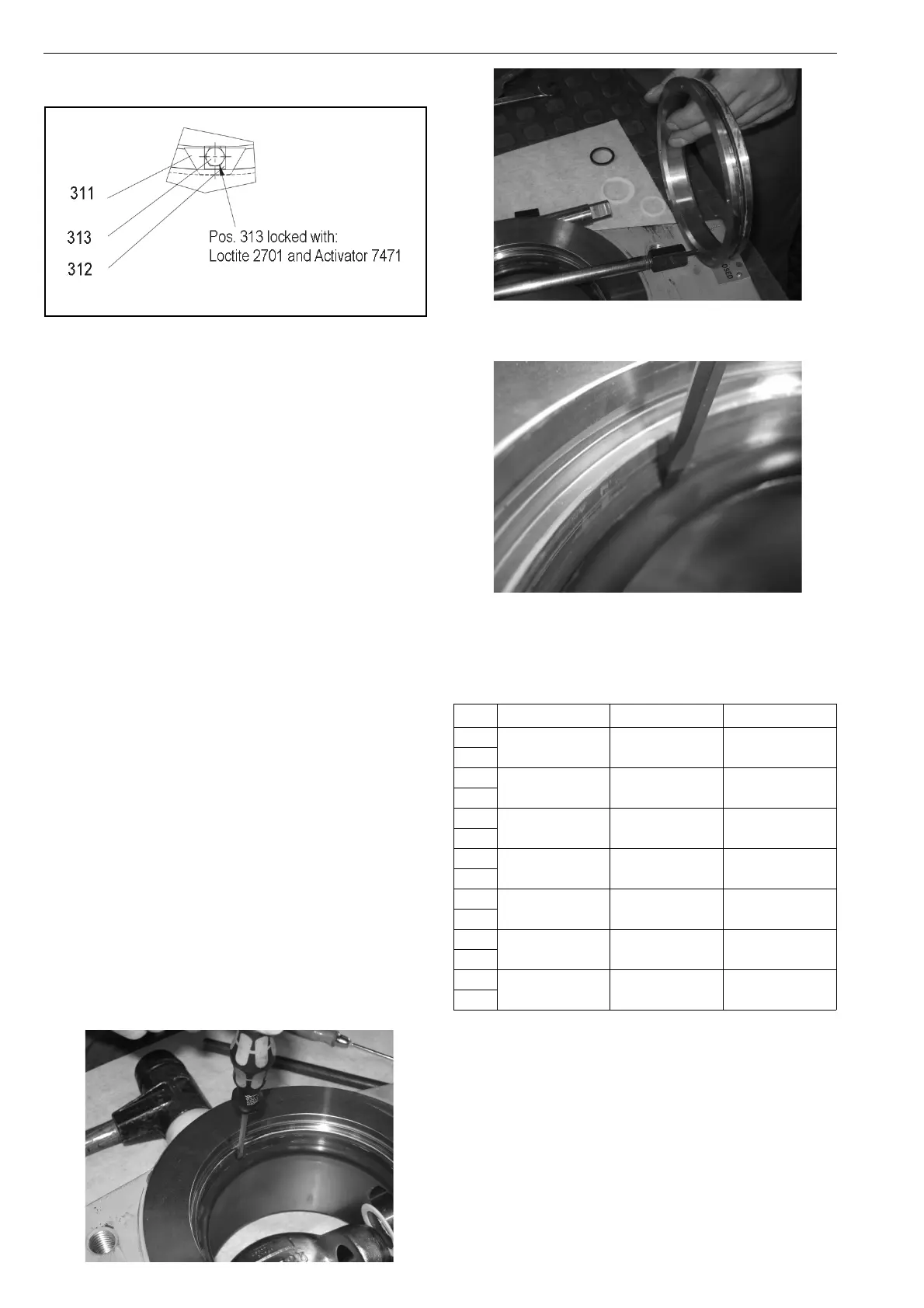

View X of Figure 24

Figure 24 Retaining ring with clamp type socket

5. The sealing element (320) and the O-ring (304) in the seal-

ing ring (301) can be replaced now (see figure 25 - 27)

Before assembling the new seals, the sealing groove in

the body (101) and the sealing ring (301) must be

cleaned carefully. Installation of the sealing ring must

be done with caution for protecting the seals from

damage.

For valve size 3"-12”/DN80-300 in class Cl300/PN40 and

3”/80DN in Cl 600/PN63

Reinstall the retaining ring (310) finally.

The retaining ring should be undamaged and may not

show any bends. The spiral coils must be properly superim-

posed in the uninstalled state. Otherwise, a new retaining

ring is to be used!

Note that that the retaining ring fully adjoins the base of

the groove along the entire perimeter. The retaining ring

must not move by the power of hand along the peripheral

direction.

For valve size 16", 20"/DN400, DN 500 in class Cl300/

PN40 and all sizes in Cl600/PN63, except 3"/DN80.

Reinstall the retaining ring (310) and the clamp type socket

(311).

The retaining ring should be undamaged and may not show

any bends. Otherwise, a new retaining ring is to be used!

Fix the screw (313) using a new tab disc (312) as well as Loc-

tite 2701 and activator 7471 (see point 3).

Information: Please read the Loctite product instructions

before use.

6. Check the high-performance valve for its seal-tightness

before reinstallation. You will find the installation

instructions in chapter 3.3.

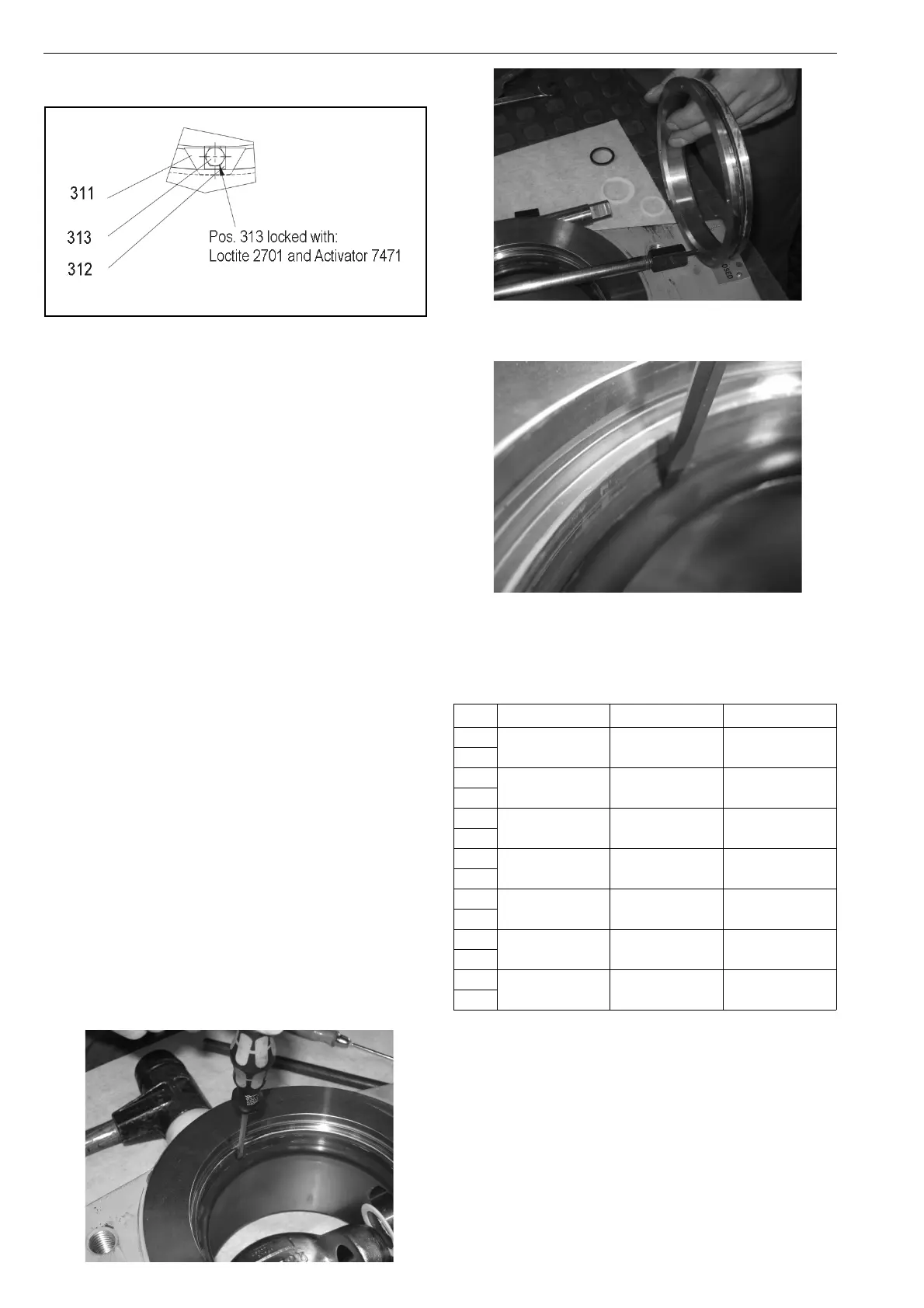

Figure 25 Replacing sealing element

Figure 26 Sealing ring with O-ring

Figure 27 Replacing sealing element

10.7 Maximum allowable closing torques of the

valves without drive at 0 bar

Torque Mc in Nm

The torque exceeds the tolerance limits of the sealing ele-

ment. The torques applies to ungreased sealing elements.

The values should not be exceeded.

The valve should also be tested with a differential pressure

in the seated position, if possible. Strongly deviating tor-

ques refer to unallowable diametrical clearance or

improper seating of the sealing element. The use of another

sealing element can eliminate the problem depending on

the specific case.

CL DN Mc PS=0bar Mc PS=40bar

300

80 / 3" 30 70

600

300

100 / 4" 30 70

600

300

150 / 6" 40 120

600

300

200 / 8" 40 220

600

300

250 / 10" 80 550

600

300

300 / 12" 200 670

600

300

400 / 16" 350 1350

600

Loading...

Loading...