2 BAR 70 en 21

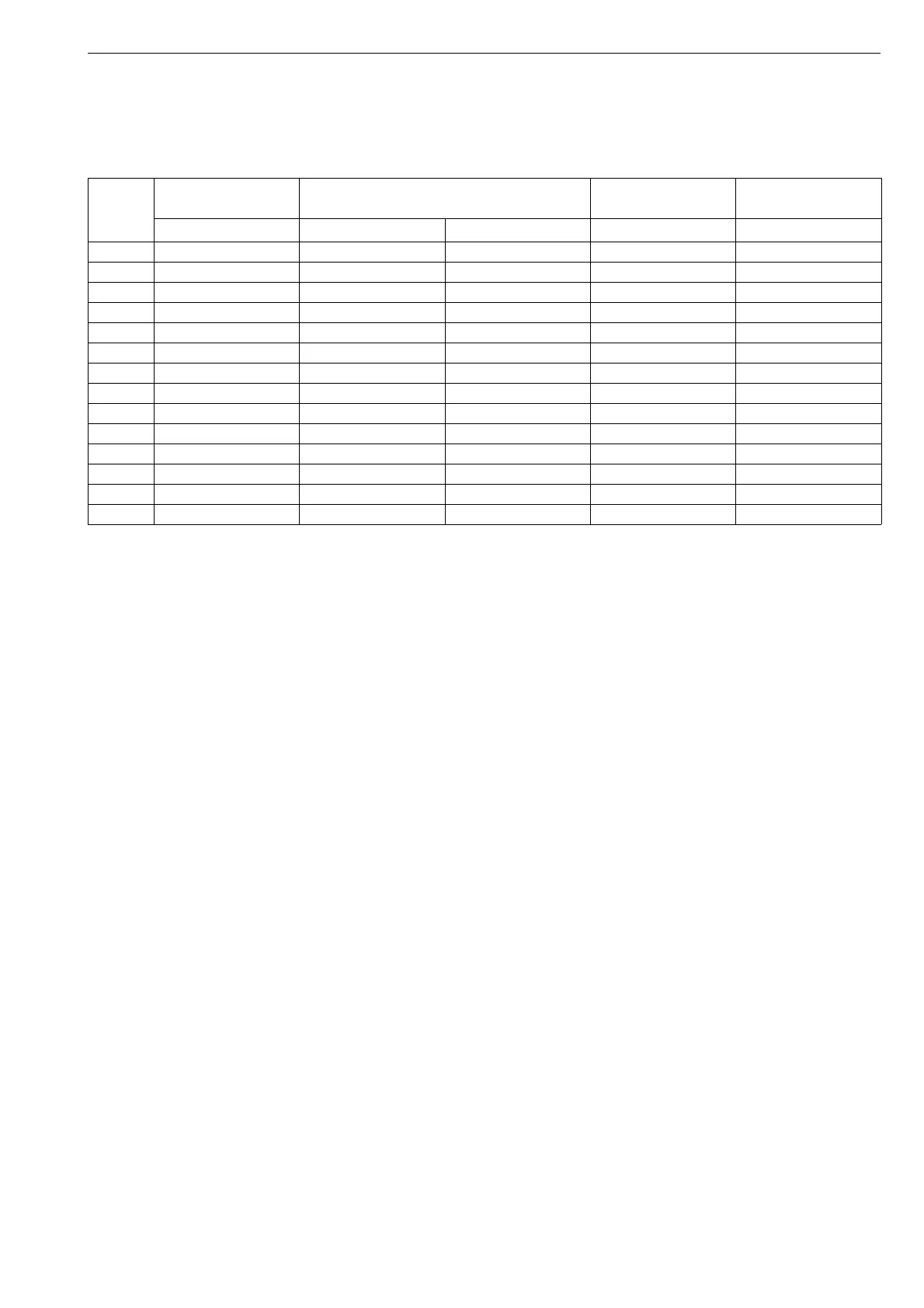

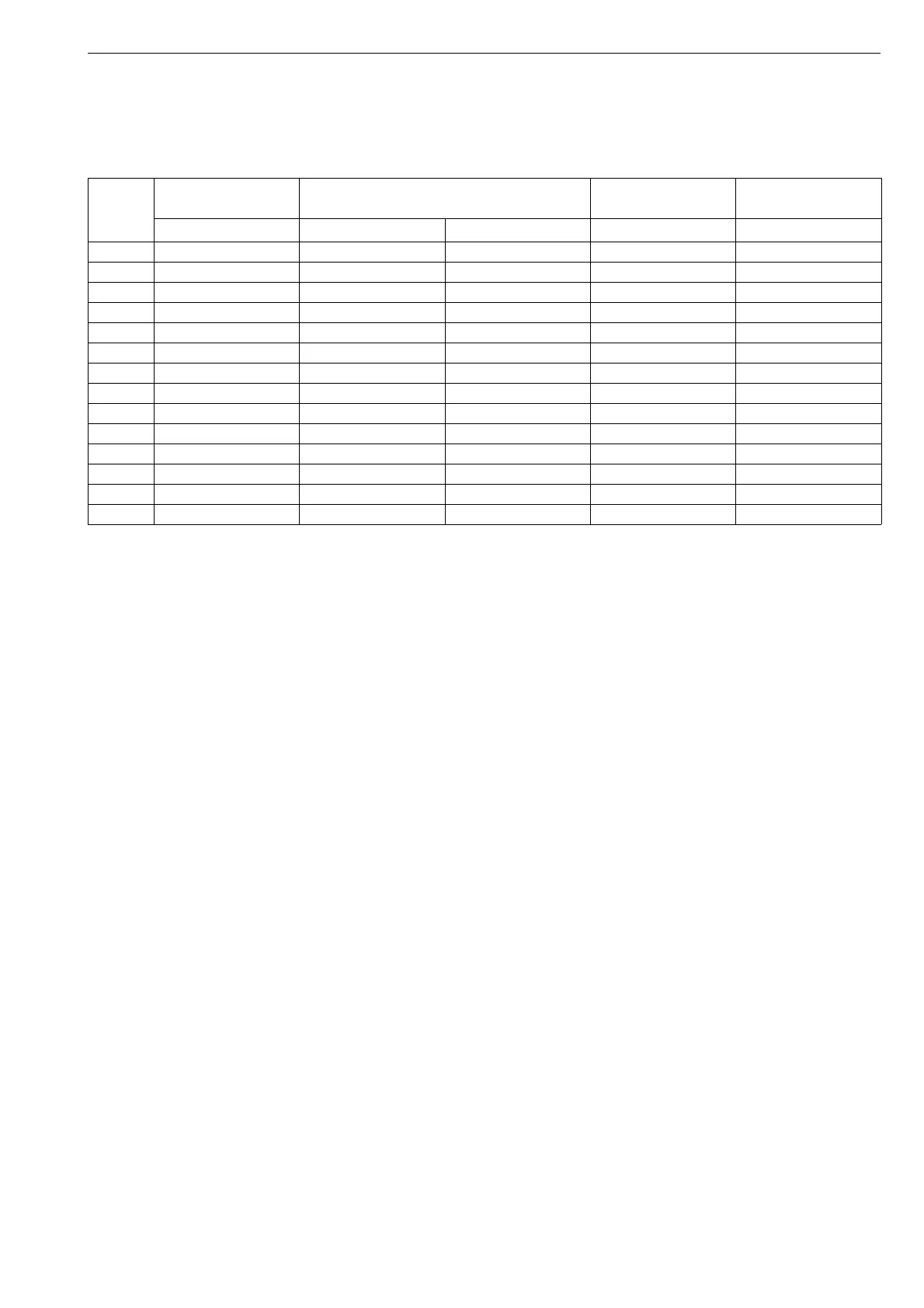

10.9 Tightening torque of valve screws

Allowable tightening torques for screws of the steel type

A2- 70.2 and A4-70 with metric coarse-pitch thread accord-

ing to DIN 13.70% utilization Rp 0.2, friction coefficient 0.16.

1) Values correspond to 100% of the 0.2% yield strength

11 Type BA Throttle valve

11.1 O-Ring design

Product description and functional description

High-performance control valve type BA, control disc cen-

trically mounted.

Body types:

□ Type BAR3 Flange

□ Type BAR6 Wafer

□ Type BAR4 Lug

Nominal sizes:

□ DN80, 100, 150, 200, 250, 300, 400, 450, 500

□ NPS 3, 4, 6, 8, 10, 12, 16, 20

Pressure classes:

□ PN 40, 63

□ CLASS 300, 600

Functional description:

A control disc centrically and rotationally mounted in the

body is moved over an outwardly guided shaft by means of

an actuator. The valve does not possess any seal-tightening

function.

Ø

stressed cross-section

Load

1)

Force at the shaft

Prestressing force Tightening torque

AS in mm

2

R

p 0,2

in N R

m

in N N Nm

M4 8,8 3951 6146 2489 2,13

M5 14,2 6390 9940 4026 4,19

M6 20,1 9045 14070 5698 7,3

M8 36,6 16470 25620 10376 17,5

M10 58,0 26100 40600 16443 35,2

M12 84,3 37935 59010 23899 60,3

M14 115,0 51750 80500 32603 95,8

M16 157,0 70650 109900 44510 146,2

M18 192,0 86400 134400 54432 203,1

M20 245,0 110250 171500 69458 285,7

M22 303,0 75750 151500 47723 212,4

M24 353,0 88250 176500 55598 273,9

M27 459,0 114750 229500 72293 405,3

M30 561,0 140250 280500 85358 549,0

Loading...

Loading...