4 2 BAR 70 en

1.4 Scope of delivery

The on/off (butterfly) valve is delivered in one of three pos-

sible designs, namely the flange, sandwich or monoflange

version.

The on/off (butterfly) valve is delivered completely along

with the drive.

1.5 Visual inspection

Prior to leaving Mapag factory, the on/off (butterfly) valve

has been checked by our quality assurance department for

seal-tightness and function and set for operation according

to the job-related documents.

Please test the on/off (butterfly) valve for possible shipping

damage prior to installation. Should parts of the delivery

show damage, please report this immediately to our quali-

fied personnel.

Check the on/off (butterfly) valve for its function before

installation. Please proceed as follows:

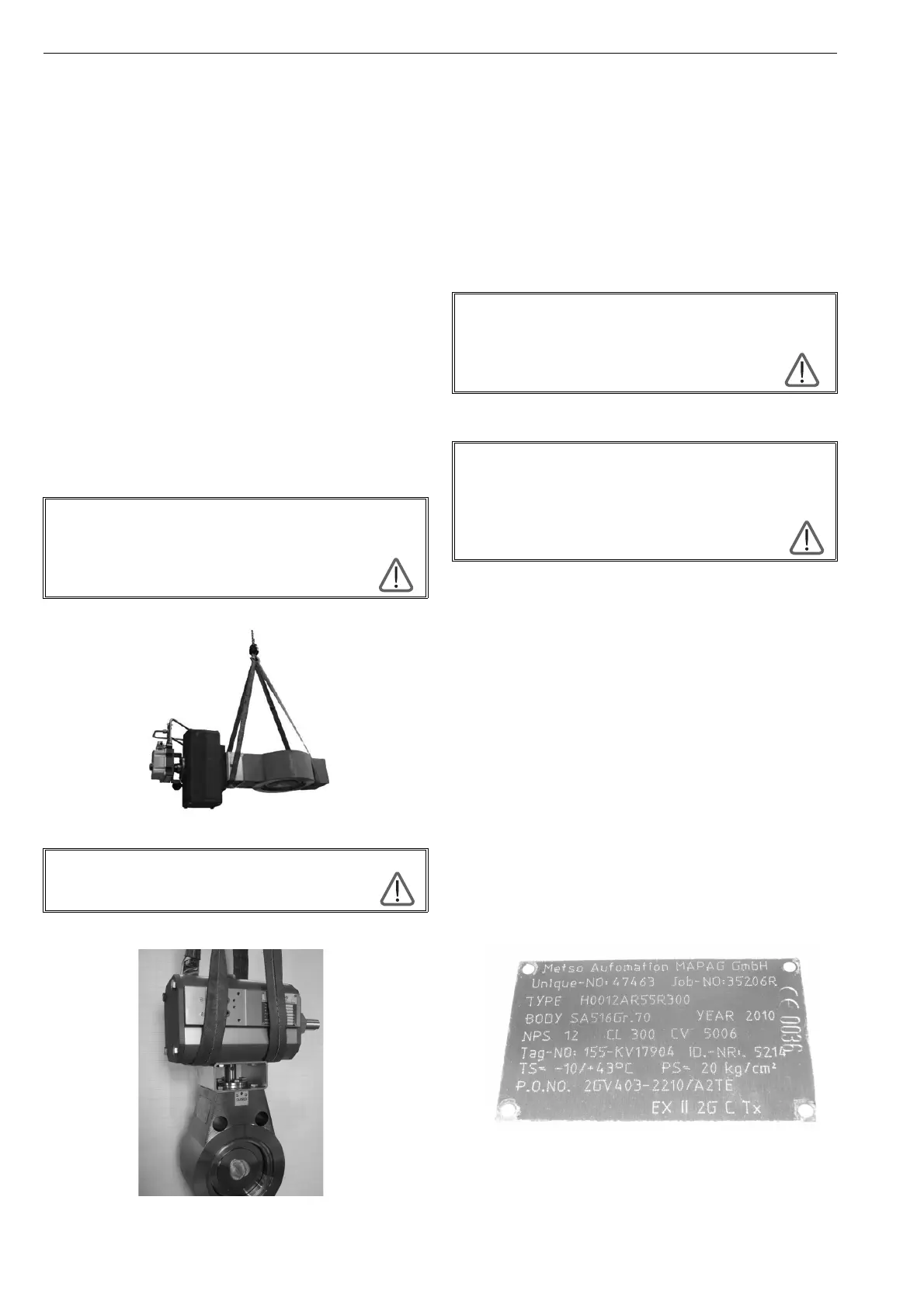

□ Depending on the size and weight of the on/off (butter-

fly) valve, you will require a hoisting rope.

Figure 1

Figure 2

□ Visual inspection – are all screws properly tightened?

□ Visual inspection for damage to the following compo-

nents

□ Disc

□ Drive shaft

□ Actuator and instrumentation

□ Piping and tubings

□ Gland packings

□ Sealing element

□ Sealing surfaces of the valve

□ Place the on/off (butterfly) valve in a vertical position.

□ Connect the power supply now. Reassure yourself that

the actuator opens into the correct direction of flow.

□ Test the function of the on/off (butterfly) valve. Allow

the on/off (butterfly) valve to open and close many

times. The stop of the drive ensures that the on/off disc

cannot be turned beyond the factory-set closed posi-

tion.

□ Disconnect the energy supply after the functional test.

If the on/off (butterfly) valve does not work flawlessly in the

functional test, please contact our qualified personnel.

Indications for this may be:

□ The valve does not move, moves too slowly or not uni-

formly

□ Unusual running noise can be heard

□ The disc does not move completely into the seated posi-

tion

□ The disc does not open completely

1.6 Marking and identification

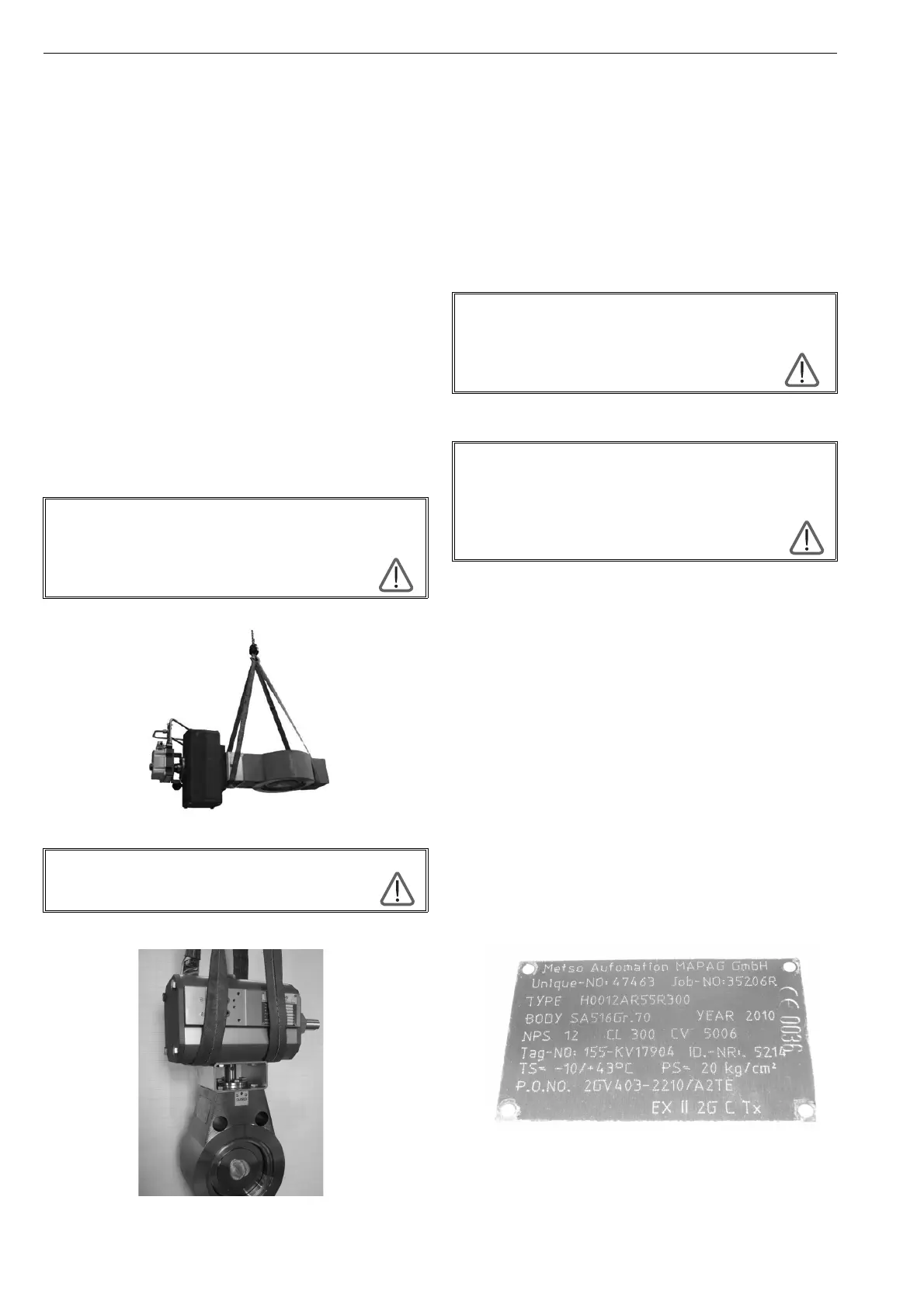

Figure 3 Identification plate

In horizontal transport position, always secure the

round sling to the body (see figure 1).

The shaft may be damaged if you secure the slings to

the actuator.

Caution: Twisting hazard!

In vertical transport position, secure the round sling

to the actuator (see Figure 2)

The on/off (butterfly) valve may show uncontrolled

movements during the functional test. Therefore,

ensure that the on/off (butterfly) valve does not

move or tip over during the

functional test under any circumstances.

The following applies in general:

For top view of the drive shaft of the valve:

Left-handed rotation = opening, right-handed

rotation = closing (see Figure 4).

(where appropriate, change according to

job-related specification)

Loading...

Loading...