METTLER TOLEDO IND360fill/dose Application EtherNet/IP Engineering Notes

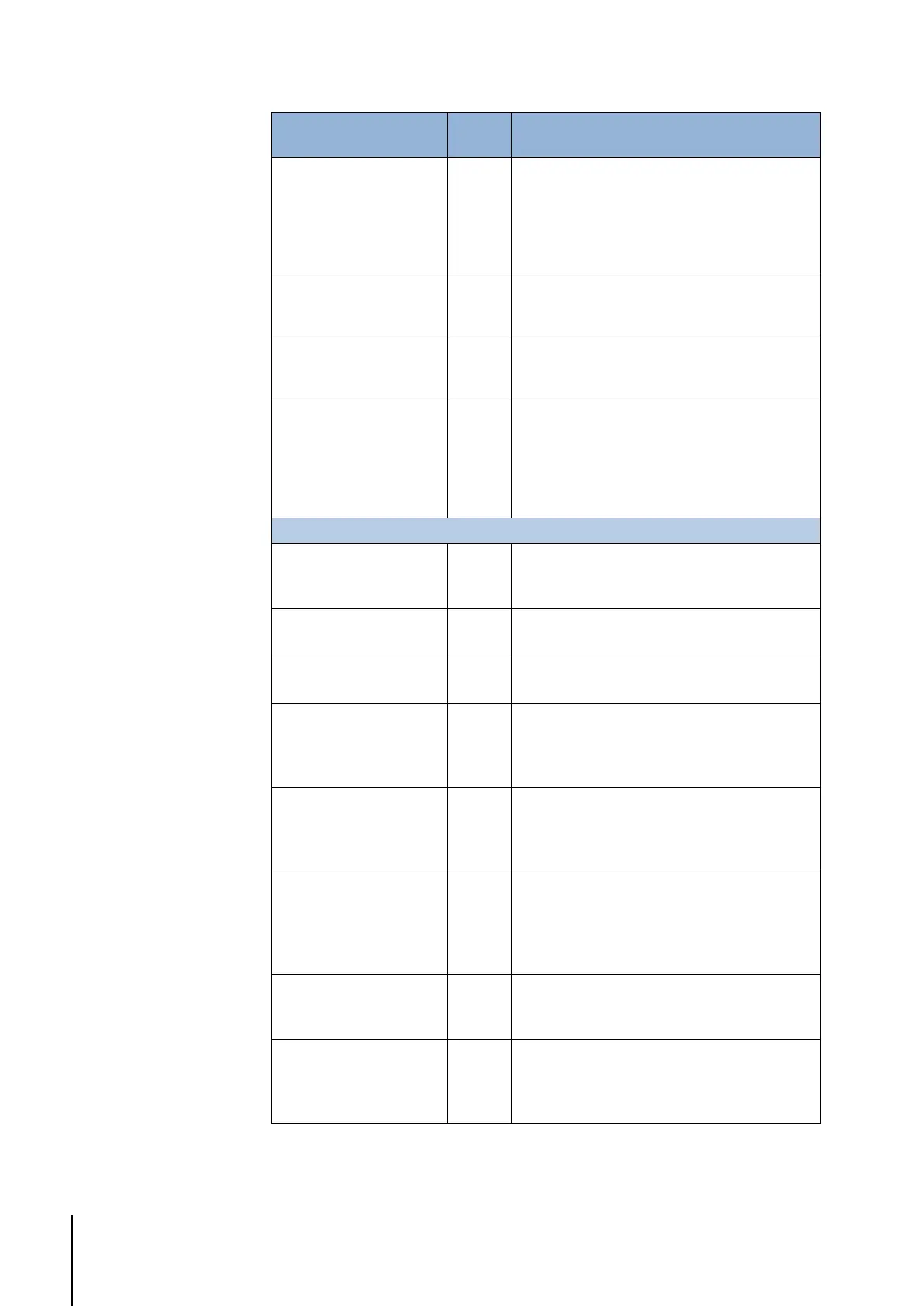

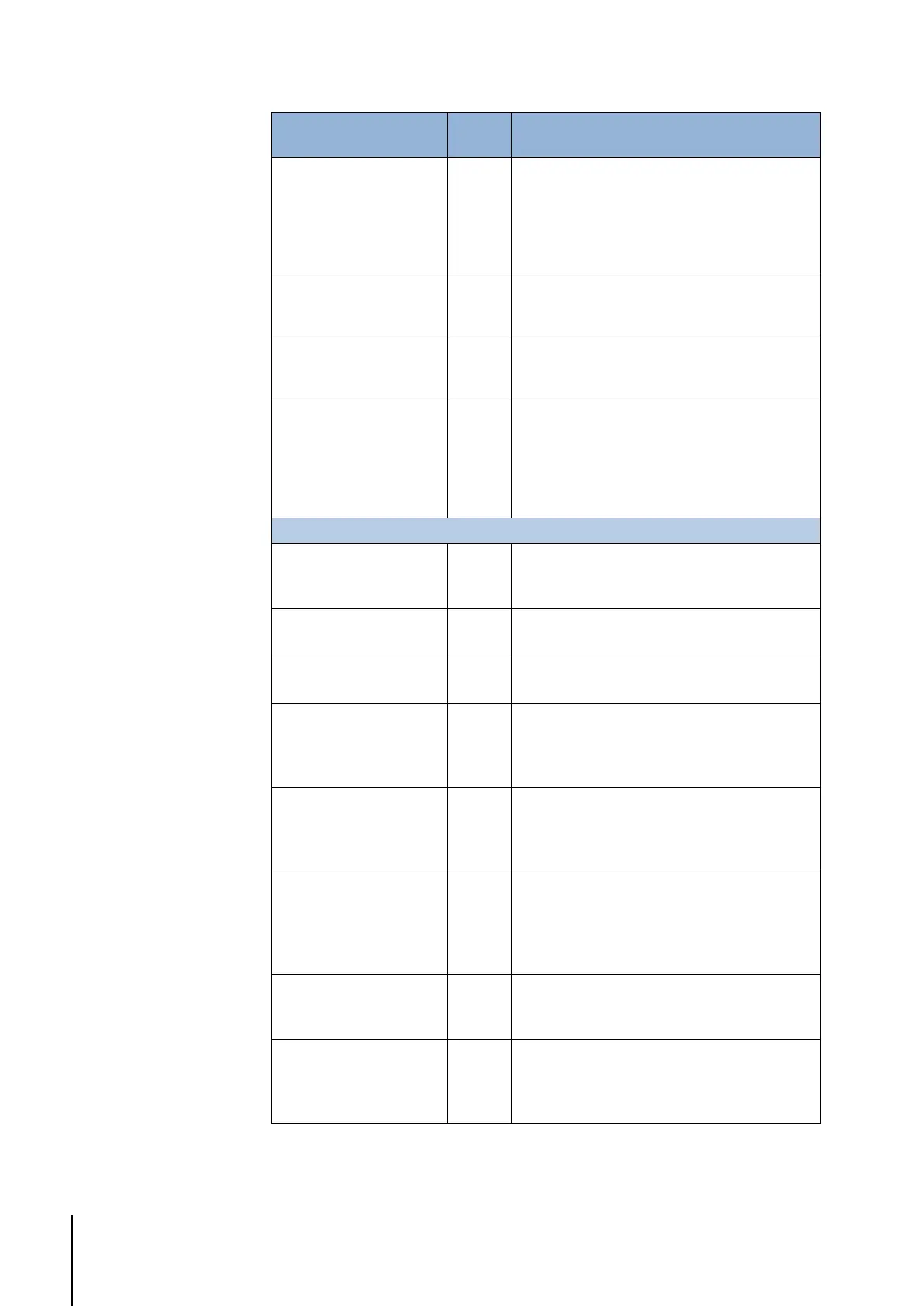

This should always be set to MB1_Response

value of the IND360. Once a cyclic command

is successfully executed, MB_Response =

MB_Command. The AOI uses this information

to detect if a command has been executed

successfully or if an error has occurred.

This should always be set to the

SB1_Status_Group_1 of the IND360. This will

provide status information for the Application.

This should always be set to the

SB1_Status_Group_2 of the IND360. This will

provide alarm information for the Application.

This should always be set to SB1_Response

value of the IND360. Once a cyclic command

is successfully executed, SB_Response =

SB_Command. The AOI uses this information to

detect if a command has been executed

successfully or if an error has occurred.

Operation mode:

0 – Fill Dump; 1 – Refill Dose; 2 – Fill; 3 –

Dose

Number of feed speeds:

0 – One speed; 1 – Two speeds

Feed output type:

0 – Concurrent; 1 – Independent

Fill/Dump mode only. Decides whether the

dump complete signal is triggered by the heel

weight or by a set time.

0 – Weight Mode; 1 – Time Mode

Set target weight. Note that the target should be

greater than the sum of Spill, Feed and Fast

Feed.

[0 – Capacity]

Spill sets the weight of material that will be

added to (in a weigh-in cycle) or removed (in

a weigh-out cycle) from the scale after all feeds

are turned off.

[-Capacity – Capacity]

Feed sets the weight of material that will be fed

in a slow or normal speed rate.

[0 – Capacity]

Fast Feed sets the weight of material that will

be fed in a fast speed rate. Used with Two

Speed filling only.

[0 – Capacity]

Loading...

Loading...