WHEELS

AND

TYRES

Jacking

up

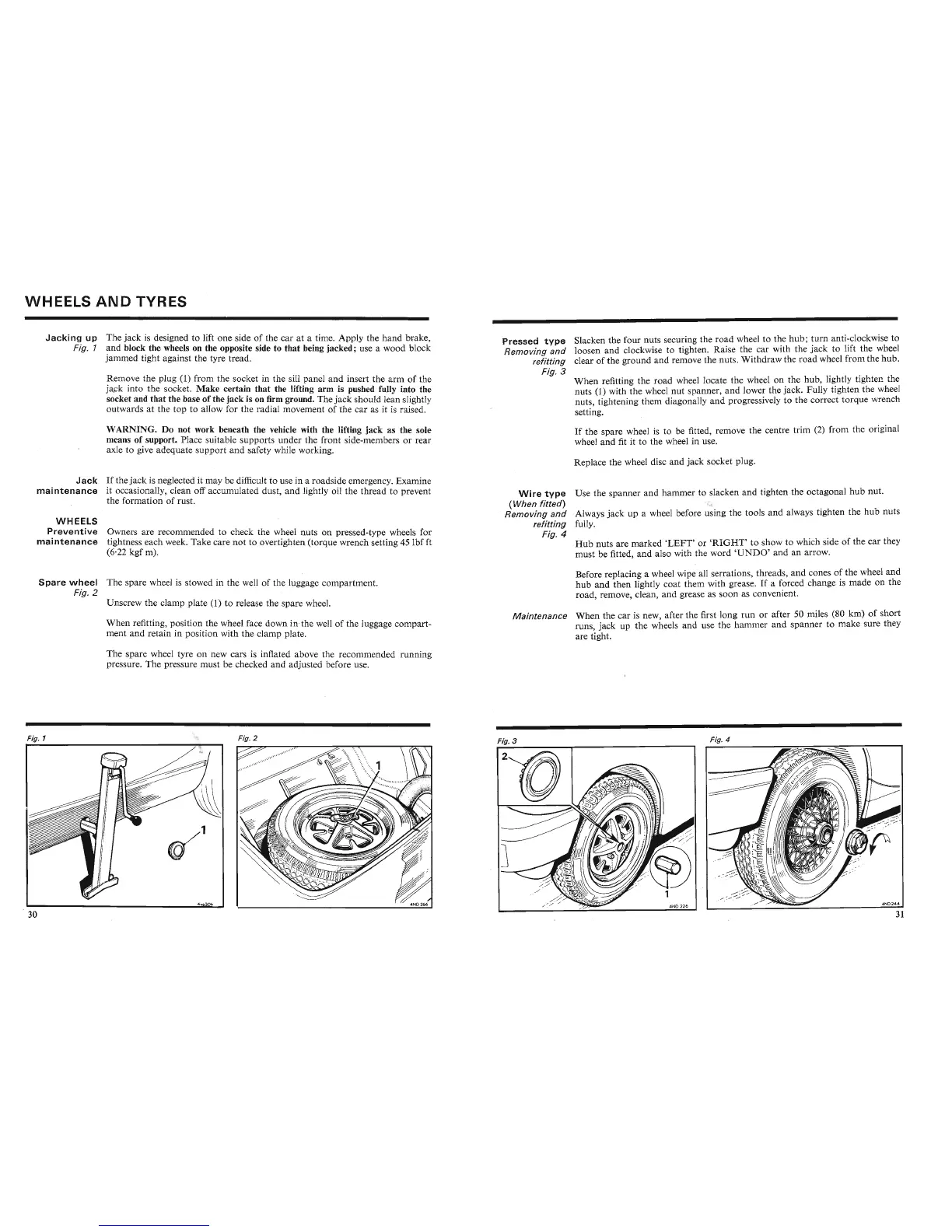

The jack is designed to lift

one

side of the car at a time. Apply the

hand

b

rake

,

Fig. 1 and block the wheels on the opposite side to that being jacked; use a wood block

jammed tight against the tyre tread.

Remove the plug (1) from the socket in the sill panel

and

insert the

arm

of the

jack into the socket.

Make

certain that the lifting arm is pushed fully into the

socket and

that

the base of the jack is on firm ground. The

jack

should lean slightly

outwards at the top to allow for the radial movement of the car as

it is raised.

WARNING. Do not work beneath the vehicle with the lifting jack as the sole

means of support. Place suitable supports under the front side-members or

rear

axle to give adequate support

and

safety while working.

Jack

If

the

jac

k is neglected it may be difficult to use in a roadside emergency. Examine

maintenance

it occasionally, clean off accumulated dust,

and

lightly oil the thread to prevent

the formation of rust.

WHEELS

Preventive

Owners are recommended to check the wheel nuts on pressed-type wheels for

maintenance

tightness each week. Take care

not

to overtighten (torque wrench setting

45lbf

ft

(6·22 kgf m).

Spare

wheel

The spare wheel is stowed in the well of the Iuggage compartment.

Fig. 2

Unscrew the clamp plate (1) to release the spare wheel.

When refitting, position the wheel face down in'the well of the luggage compart-

ment

and

retain in position with the clamp plate.

The spare wheel tyre on new cars is inflated above the recommended running

pressure. The pressure must be checked

and

adjusted before use.

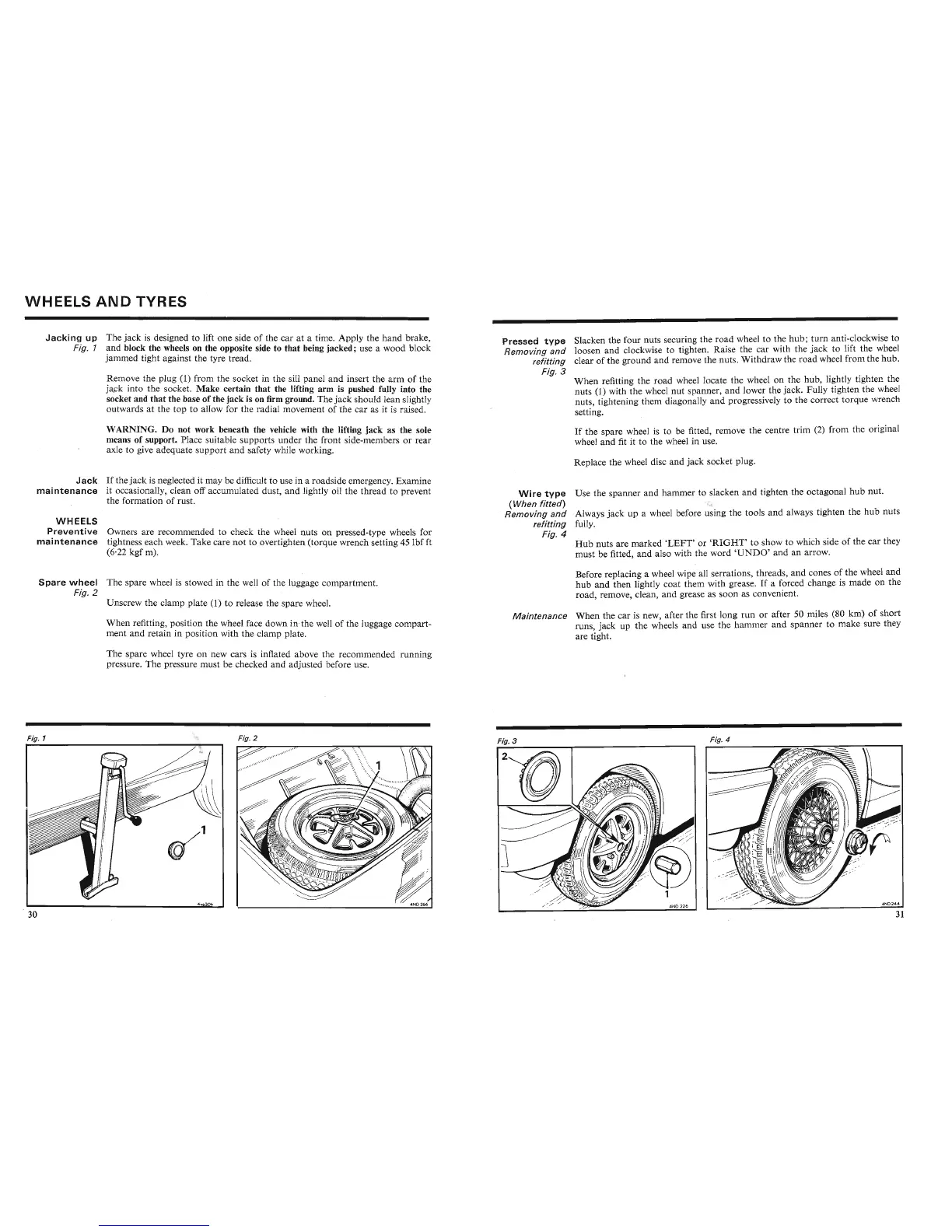

Pressed

type

Slacken the four nuts securing the

road

wheel to the

hub;

turn

anti-clockwise to

Removing

and

loosen

and

clockwise to tighten. Raise the car with the

jack

to lift the wheel

refitting clear of the ground

and

remove the nuts. Withdraw the

road

wheel from the

hub.

Fig. 3

When

refitting the

road

wheel locate the wheel on the hub, lightly tighten the

nuts (1) with the wheel nut spanner,

and

lower the jack. Fully tighten the wheel

nuts, tightening

them

diagonally

and

progressively to the correct torque wrench

setting.

If the spare wheel is to be fitted, remove the centre trim (2) from the original

wheel

and

fit it to the wheel in use.

Replace the wheel disc

and

jack

socket plug.

Wire

type

Use the spanner and hammer to slacken

and

tighten the octagonal

hub

nut.

(When

fitted)

Removing

and

Always

jack

up a wheel before using the tools

and

always tighten the

hub

nuts

refitting

fully.

Fig. 4

Hub

nuts are

marked

'LE

FT'

or

'RIGHT'

to show to which side of the car they

must be fitted,

and

also with the word

'UNDO

'

and

an arrow.

Before replacing a wheel wipe all serrations, threads,

and

cones of the wheel

and

hub

and

then lightly coat them with grease. If a forced change is made on the

road, remove, clean, and grease as soon as conv nient.

Maintenance

When

the car is new, after the first long

run

or aft r 50 miles (80 km) of short

runs, jack up the wheels and use th

hamm

r

and

spanner to

make

sure they

are tight.

Fig. 1

\t\1

Fig. 3

II

Fig. 4

Fig.

2

Loading...

Loading...