Emission

Control

Systems-California

UEL

SYSTEM

IR

CLEANER

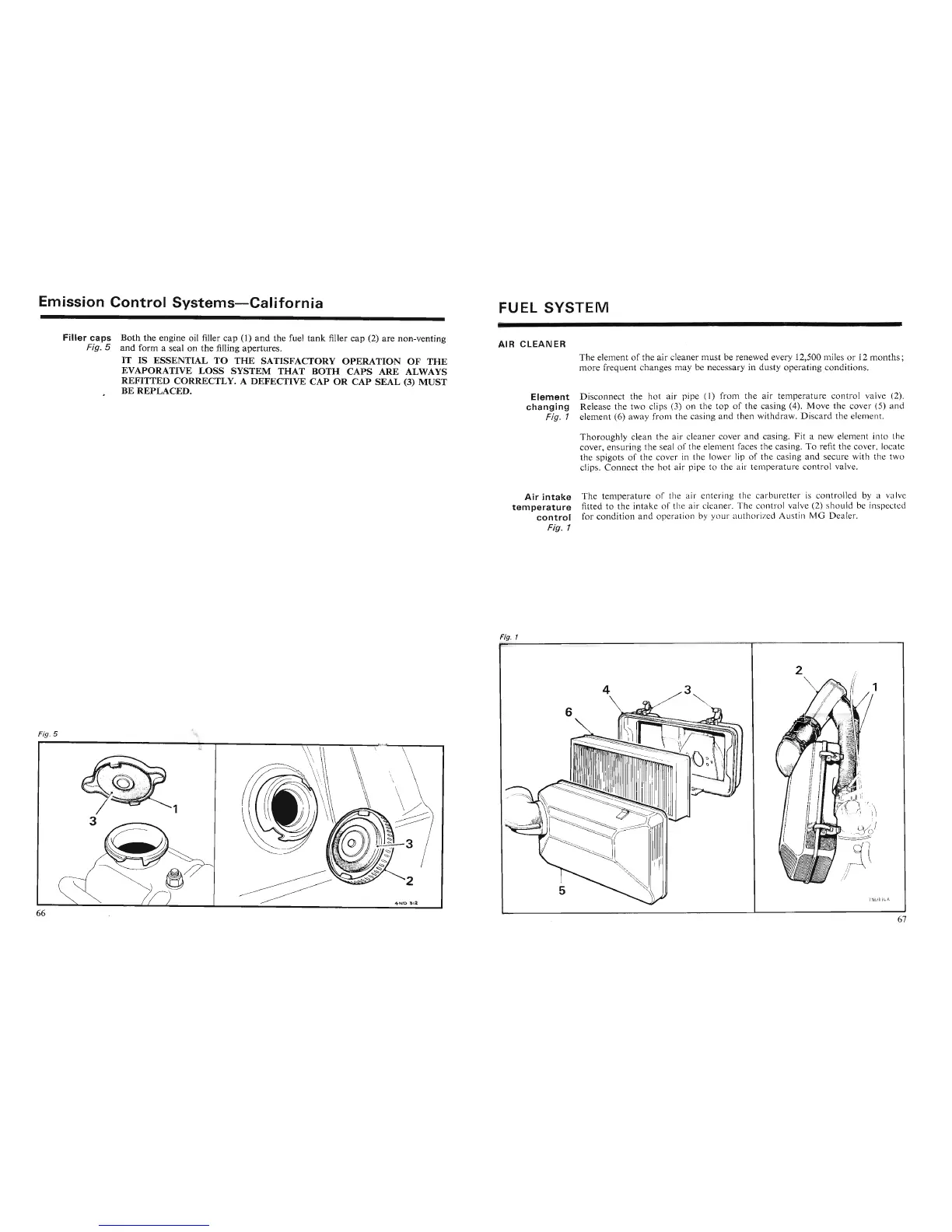

Filler

caps

Both

the engine oil filler

cap

(1)

and

the fuel

tank

filler

cap

(2) are non-venting

Fig.5

and

form a seal on

the

filling apertures.

IT IS ESSENTIAL TO THE SATISFACTORY OPERATION OF THE

EVAPORATIVE LOSS SYSTEM THAT BOTH CAPS ARE ALWAYS

REFITTED CORRECTLY. A DEFECTIVE CAP OR CAP SEAL (3) MUST

BE REPLACED.

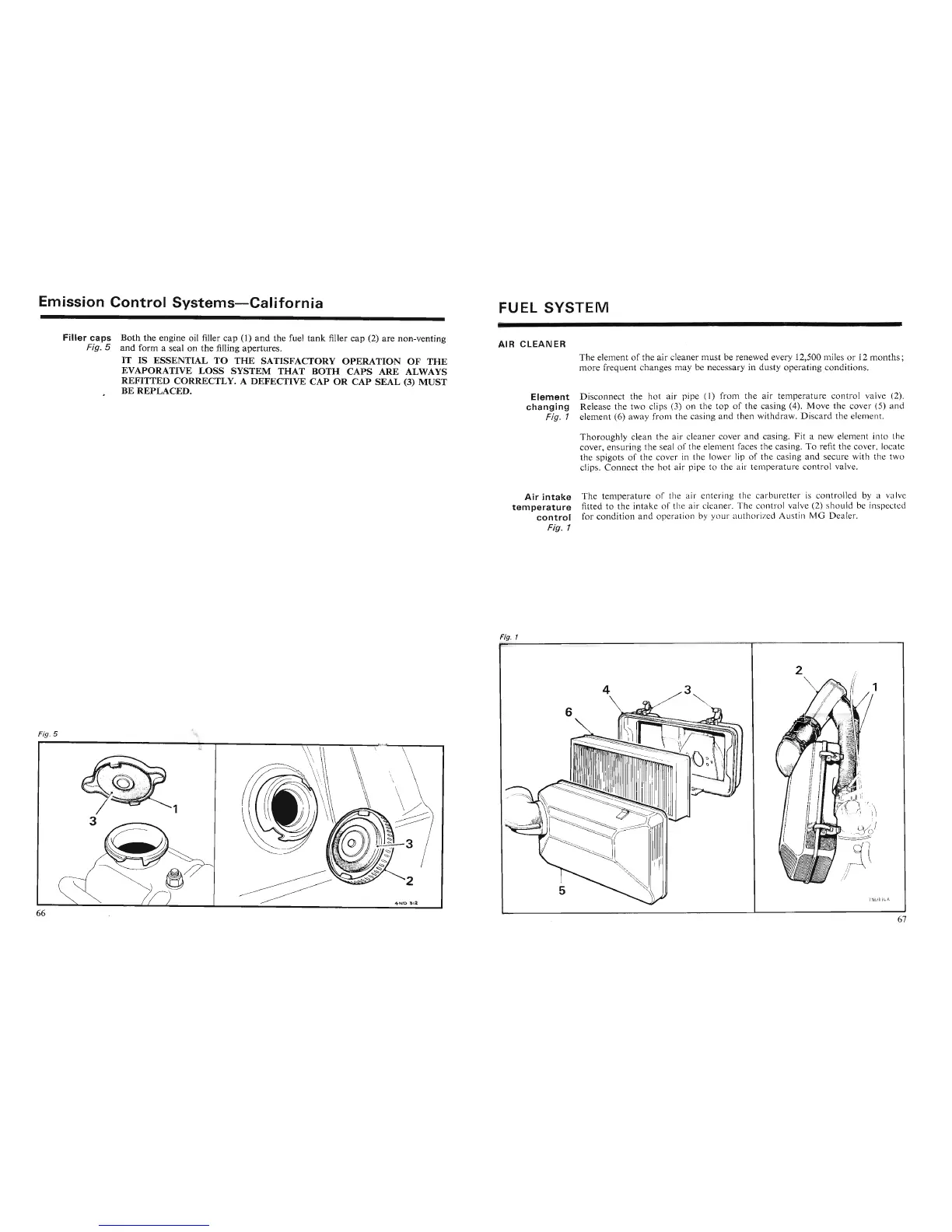

Element

changing

Fig. 1

The element of the air cleaner

must

be renewed every 12,500 miles or 12

months;

more

frequent changes may be necessary in dusty operating conditions.

Disconnect the hot air pipe

(1) from the air temperature control valve (2).

Release the two clips (3) on the top of the casing (4). Move the cover (5) and

element (6) away from the casing and then withdraw. Discard the element.

Thoroughly clean the air cleaner cover and casing.

Fit

a new element into the

cover, ensuring the seal of the element faces the casing. To refit the cover, locate

the spigots of the cover in the lower lip of the casing and secure with the two

clips.

Connect

the hot air pipe to the air temperature control valve.

Air

intake

tem

peratu

re

control

Fig. 1

The

temperature

of the air entering the carburette r is controlled by a valve

fitted to the intake of the air clea ner. The control valve (2) should be inspected

for condition

and

operati on by

your

author ized Austin

MG

Dealer.

I . 1

34

\

\

Fig. 5

Fig.

5

Loading...

Loading...