INSTALLATION AND OPERATING INSTRUCTIONS2

BOILER INSTALLATION

2.1

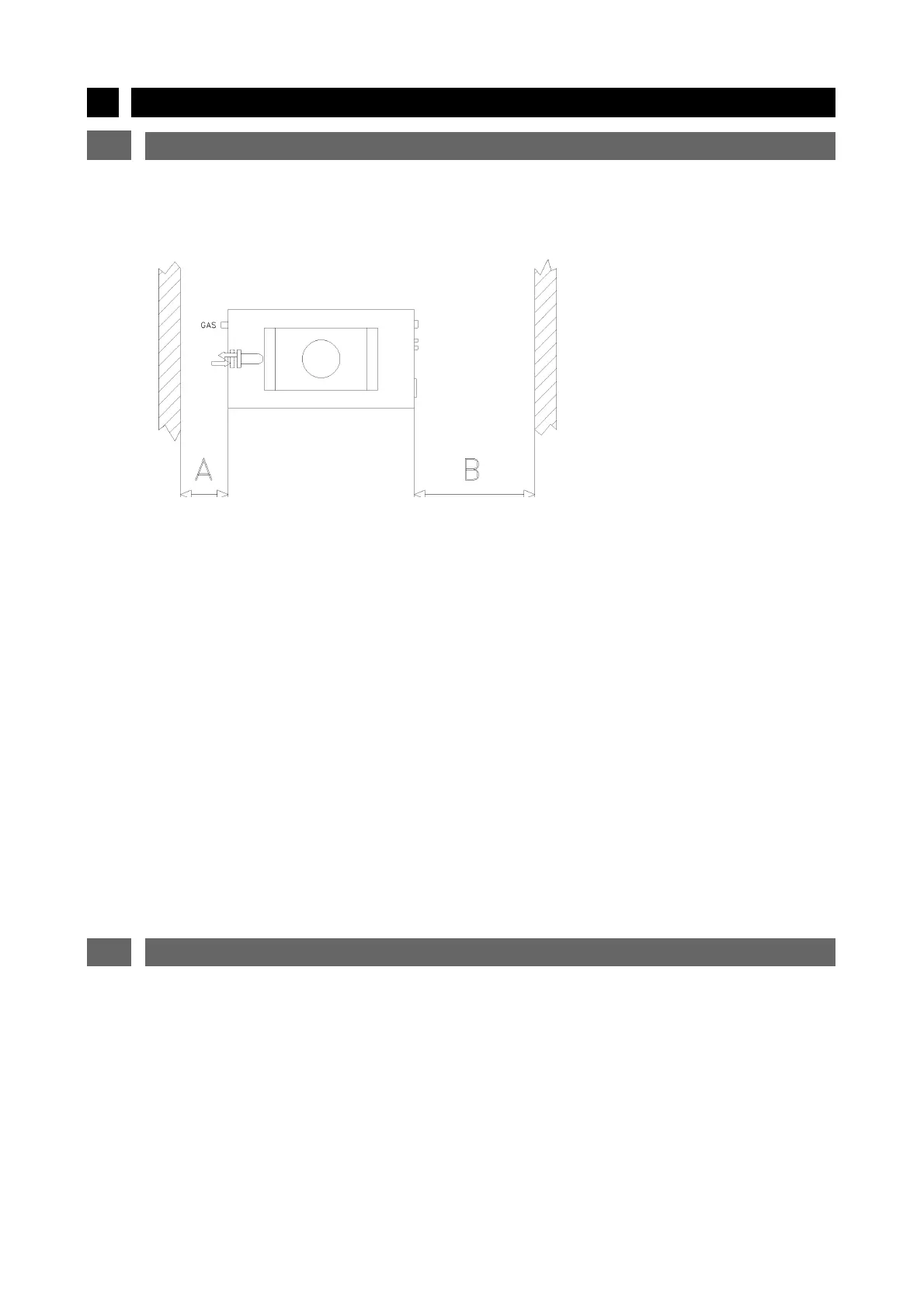

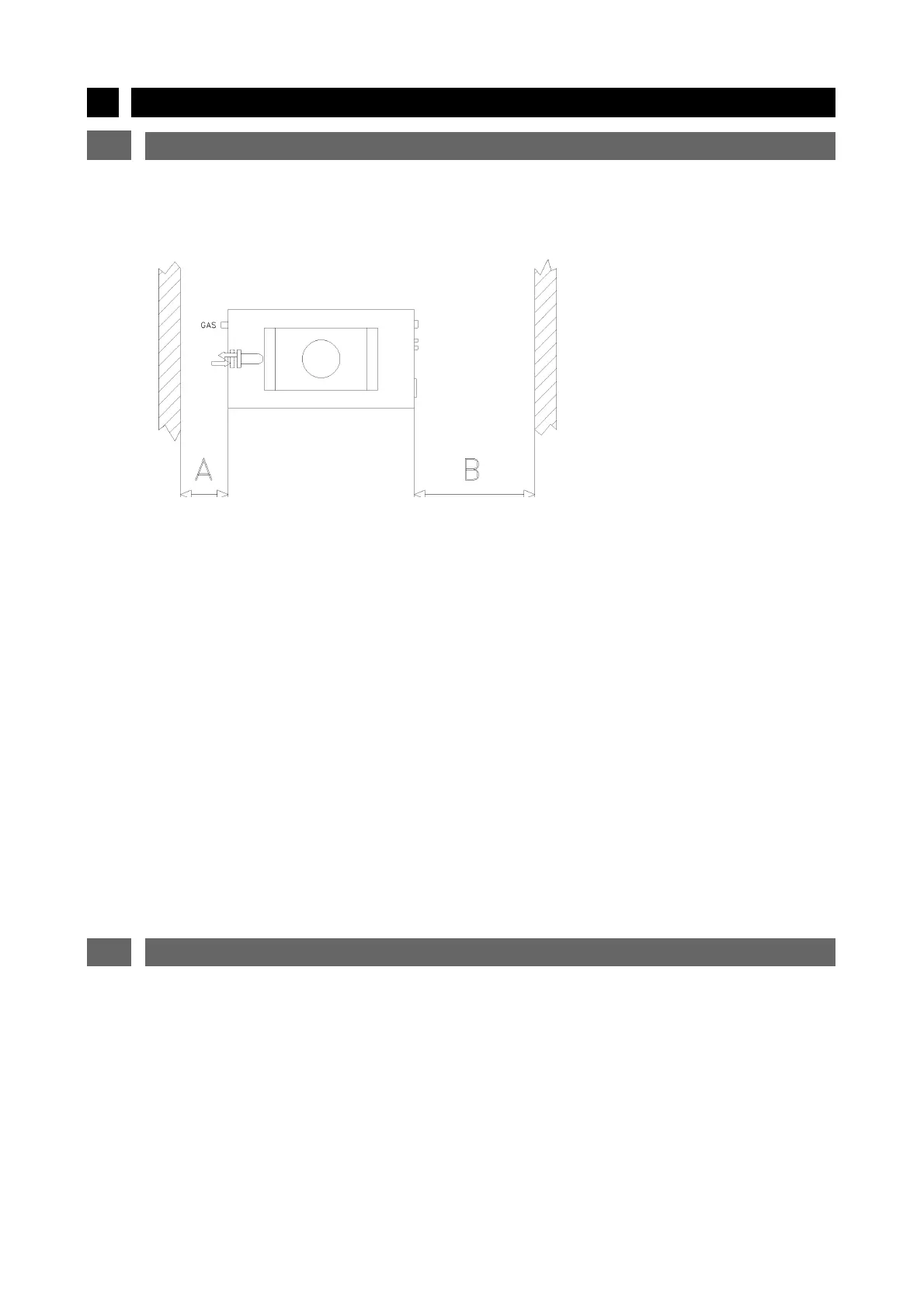

Siting of the boiler should be such that adequate space is provided at the front and rear of the unit

to facilitate the withdrawal of the burner bars during servicing. Sufficient headroom over the boil-

er should be allowed to facilitate servicing with a minimum requirement of 1000 mm.

Allow minimum of 5 mm at sides of boiler for assembly

A (rear) B (front)

REGENCY 4 MODULEK - 152 450 mm 750 mm

REGENCY 4 MODULEK - 169 500 mm 750 mm

REGENCY 4 MODULEK - 186 550 mm 750 mm

REGENCY 4 MODULEK - 203 600 mm 750 mm

REGENCY 4 MODULEK - 220 650 mm 750 mm

REGENCY 4 MODULEK - 237 700 mm 750 mm

REGENCY 4 MODULEK - 255 750 mm 750 mm

REGENCY 4 MODULEK - 272 800 mm 800 mm

The boiler is delivered as a consignment of four packages. It is supplied complete with a draught

diverter which must be fitted. The opening around this draught diverter must not be restricted in

any way (i.e. boxing in boiler in alcove, etc...).

The boiler should be mounted on a level base of non-combustible material. A split collar should

be fitted immediately above the draught diverter to allow servicing of the heat exchanger.

The availability of an adequate gas supply or the suitability of an existing supply and metering

equipment, should be established by reference to the local Gas Undertaking before installation.

Gas supply pipework should be fitted in accordance with IGE/UP/2.

Do not use pipes of a smaller size than the boiler gas connection.

GAS SUPPLY2.2

8

Loading...

Loading...