10

Low level 540 cm

2

plus 4.5 cm

2

per

(inlet) kilowatt in excess of 60 kW

total rated input (gross)

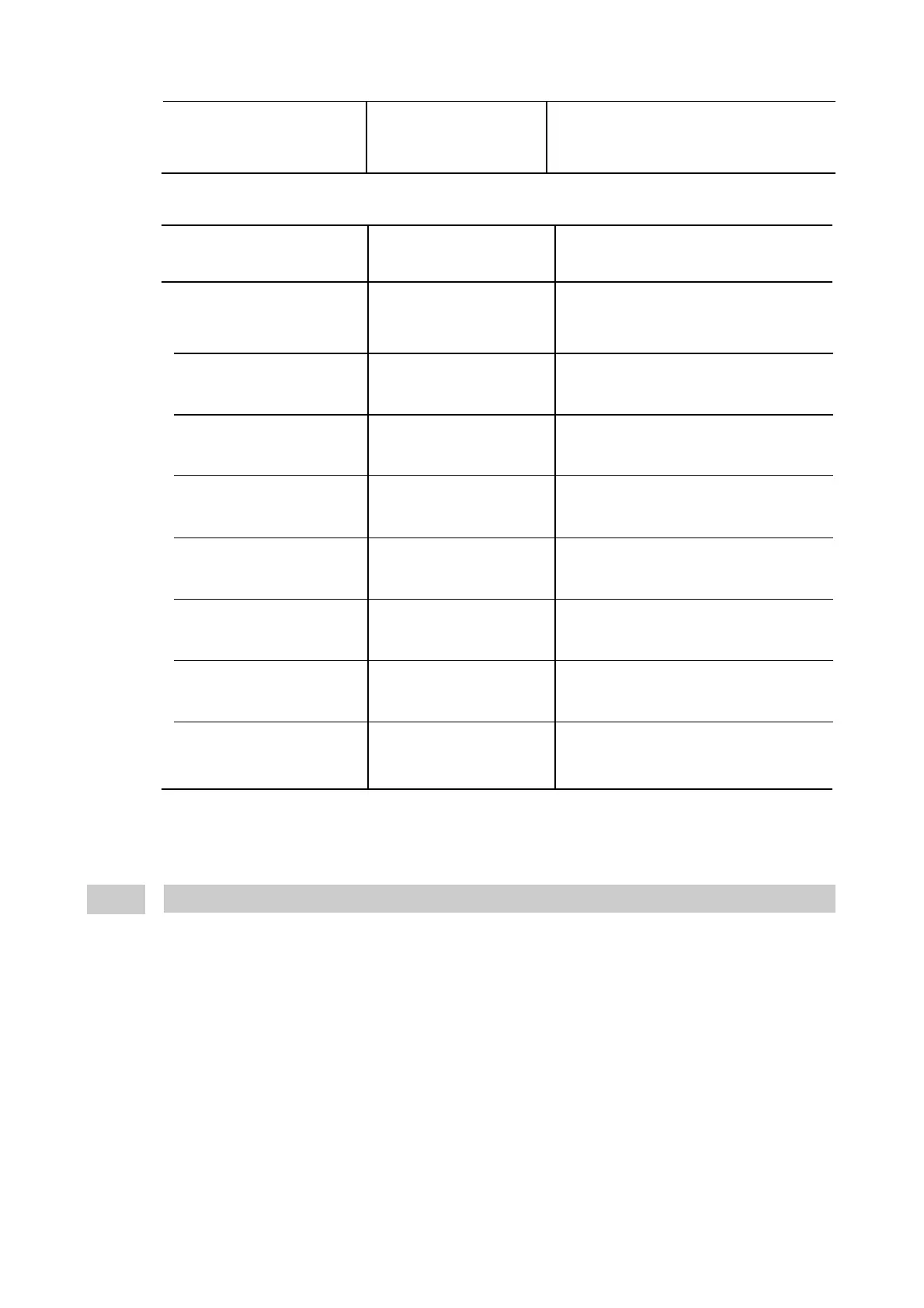

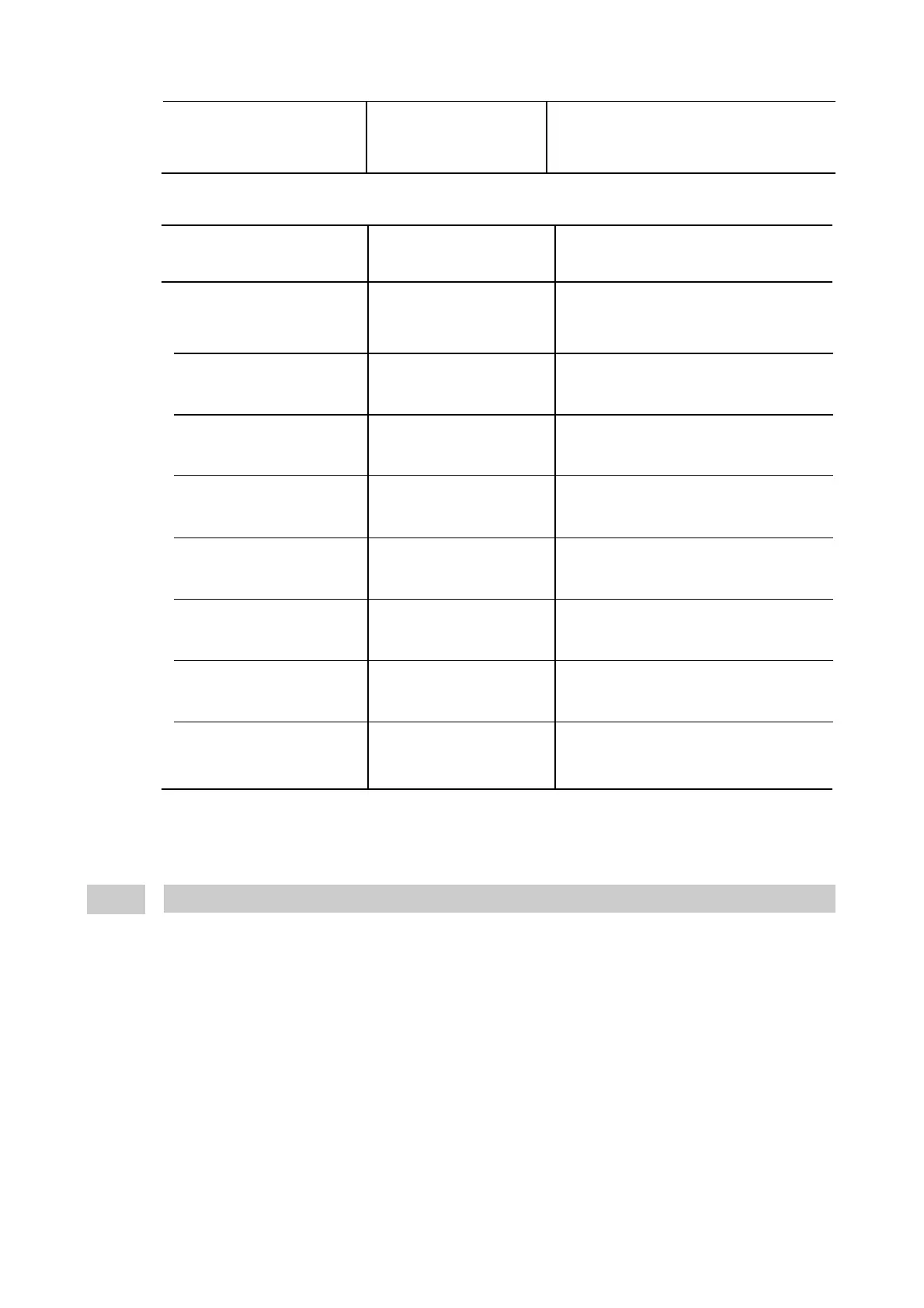

The actual minimum effective areas of the air vents required are as follows:

BOILER MODEL POSITION AREA OF VENT

OF AIR VENT (Air direct from outside)

High Level 567 cm

2

per boiler

Regency 4 Modulek-152

Low Level 1133 cm

2

per boiler

High Level 615 cm

2

per boiler

Regency 4 Modulek-169

Low Level 1230 cm

2

per boiler

High level 663 cm

2

per boiler

Regency 4 Modulek-186

Low Level 1326 cm

2

per boiler

High level 709 cm2 per boiler

Regency 4 Modulek-203

Low Level 1418 cm

2

per boiler

High level 757 cm2 per boiler

Regency 4 Modulek-220

Low Level 1514 cm

2

per boiler

High level 808 cm

2

per boiler

Regency 4 Modulek-237

Low Level 1615 cm

2

per boiler

High level 856 cm2 per boiler

Regency 4 Modulek-255

Low Level 1712 cm

2

per boiler

High level 907 cm

2

per boiler

Regency 4 Modulek-272

Low Level 1813 cm

2

per boiler

2.4.2

AIR SUPPLY BY MECHANICAL VENTILATION

Mechanical ventilation systems serving the area containing the boiler should be designed

with an extraction air rate of 0.45 m

3

/sec per 1000 kW total rated input, and an inlet air

rate of 1.1 m

3

/sec per 1000 kW total rated heat input.

Systems employing an extract fan only must not be used, whereas the use of a single inlet

fan, or an inlet together with an extract fan is acceptable.

All air inlet and extract fans should be electrically interlocked to cause safety shut-down

or lock-out of the boiler in the event of malfunction of either fan.

The requirements of mechanical ventilation schemes is fully outlined in BS.6644.

Loading...

Loading...