M‑I SWACO MONGOOSE PRO Shale Shaker

44 Field Installation and Operation Manual 9092F02001AENG (D) 44

18. PRESERVATION AND STORAGE

18.1 Storage of Non-Commissioned Equipment

Equipment can be stored (upon arrival) in the shipping crate for a 12 to 24 month preservation period. Do NOT

expose equipment to dust, vibration or extreme weather conditions (such as heavy rain). If unit has been removed

from original crate, cover with a tarpaulin during any preservation period.

Every 1-3 months, examine the motors. Remove their weight covers and rotate the counterweight to preserve the

bearings.

18.2 Storage of Commissioned Equipment

When preparing a commissioned piece of equipment for storage, take the following steps to make sure it is

protected:

1. Reinstall original shipping brackets to protect equipment.

2. When disconnecting power connections to control station and motors, plug all inlets with an appropriate fitting

to keep water/moisture from entering. Do NOT leave any electrical connections open and exposed.

3. Add anti-condensation packs to motor junction boxes and control station.

4. Install and seal all control station doors and junction box covers.

5. Wash unit to remove any media from shaker basket, feeder and skid.

6. Remove screens.

7. Disconnect flow line from the feeder.

8. Disconnect main power line from isolator.

9. Attach shipping brackets to basket and skid.

10. Open air valves to relieve air pressure.

11. Disconnect air supply.

12. Move or transport shaker via lifting points indicated on skid.

13. Cover air line connections to prevent contaminants from entering the system.

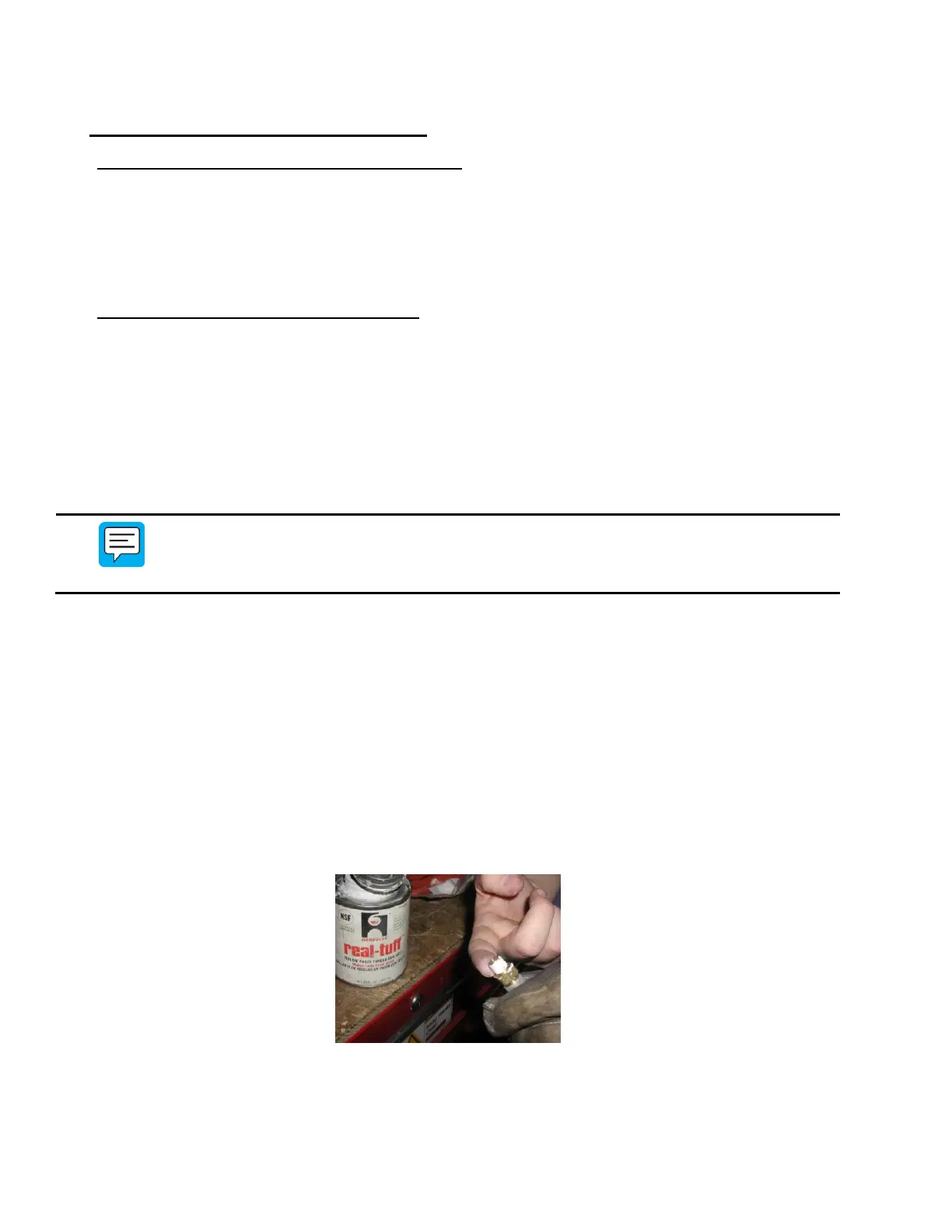

Figure 35. Sealant Applied on a Plug Thread

Loading...

Loading...