24 ACDC200LCD

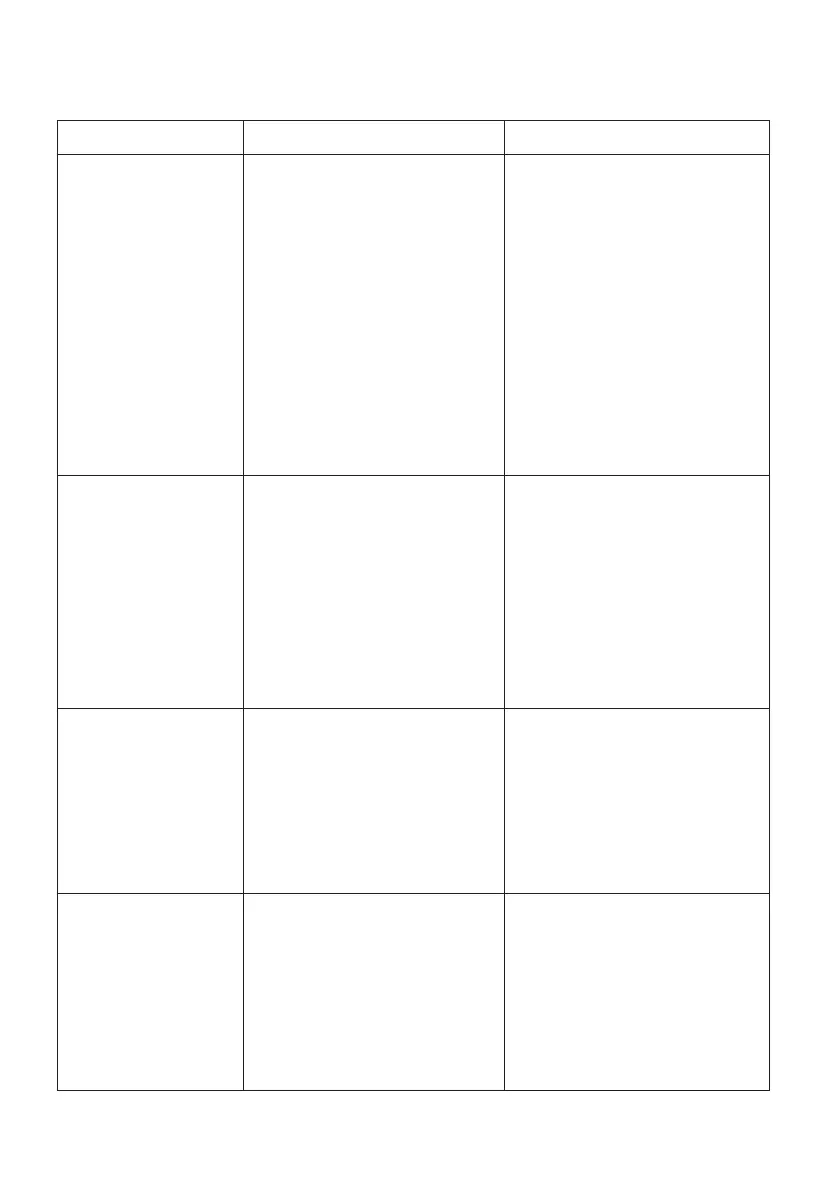

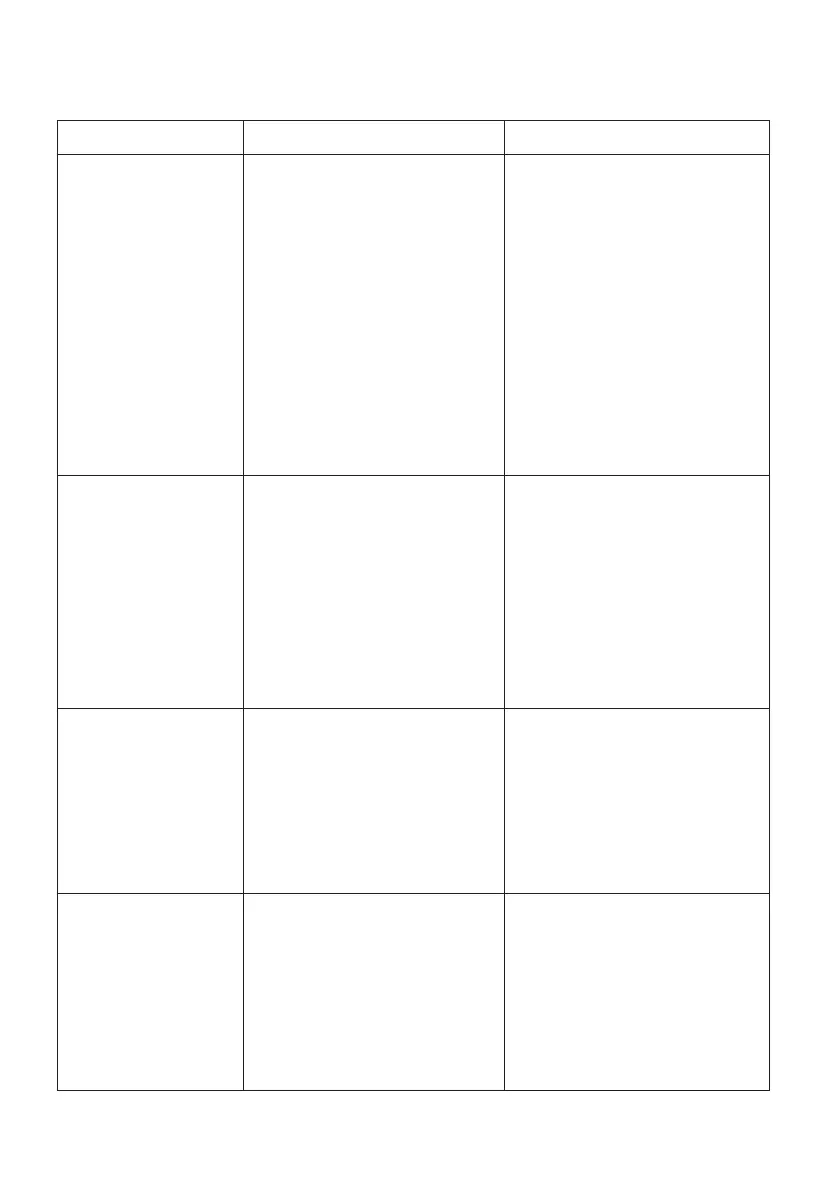

Trouble Shooting Guide for Gas Tungsten Arc Welding

Problem Analysis Solutions

Excessive Electrode

Consumption

1. Inadequate gas ow

2. Operating on reverse

polarity

3. Improper size electrode

for current required

4. Excessive heating in

holder

5. Contaminated electrode

6. Electrode oxidation during

cooling

7. Using gas containing

oxygen or CO²

1. Increase gas glow

2. Use large electrode or

change to straight polarity

3. Use larger electrodes

4. Check for proper collet

contact

5. Remove contaminated

portion. Erratic results

will continue as long as

contamination exists

6. Keep gas owing after

stopping arc for at least

10 – 15 seconds

7. Change to proper gas

Erratic arc

1. Base metal is dirty or greasy

2. Joint too narrow

3. Electrode is contaminated

4. Arc too long

1. Use appropriate chemical

cleaners, wire brush

or abrasives

2. Open joint groove, bring

electrode closer to work,

decrease voltage

3. Remove contaminated

portion of electrode

4. Bring holder closer to work

to shorten arc

Porosity

1. Entrapped gas impurities

(hydrogen, nitrogen, air,

water, vapour)

2. Defective gas hose or

loose hose connections

3. Oil lm on base metal

1. Blow out air from all lines

before striking arc. Use

welding grade (99.99%)

inert gas

2. Check hose and

connections for leaks

3. Bring holder closer to work

to shorten arc

Tungsten

contamination of

work piece

1. Contact starting with

electrode

2. Electrode melting and

alloying with base metal

3. Touching tungsten

metal pool

1. Using high frequency

start or using copper

striker plate

2. Use less current or

larger electrode

3. Keep tungsten out of

molten pool

Loading...

Loading...