25OPERATING MANUAL

Problem Analysis Solutions

Excessive ceramic

cup usage

1. Excess duty of cycle

torch

2. Too small a nozzle bore

for size of tungsten

3. Thermal shock

1. Change torch

2. Increase bore of nozzle

3. Increase bore of nozzle or

warm ceramic cup slowly

from cold

Striking the arc method following step:

1. Open the gas valve on the Lift TIG torch.

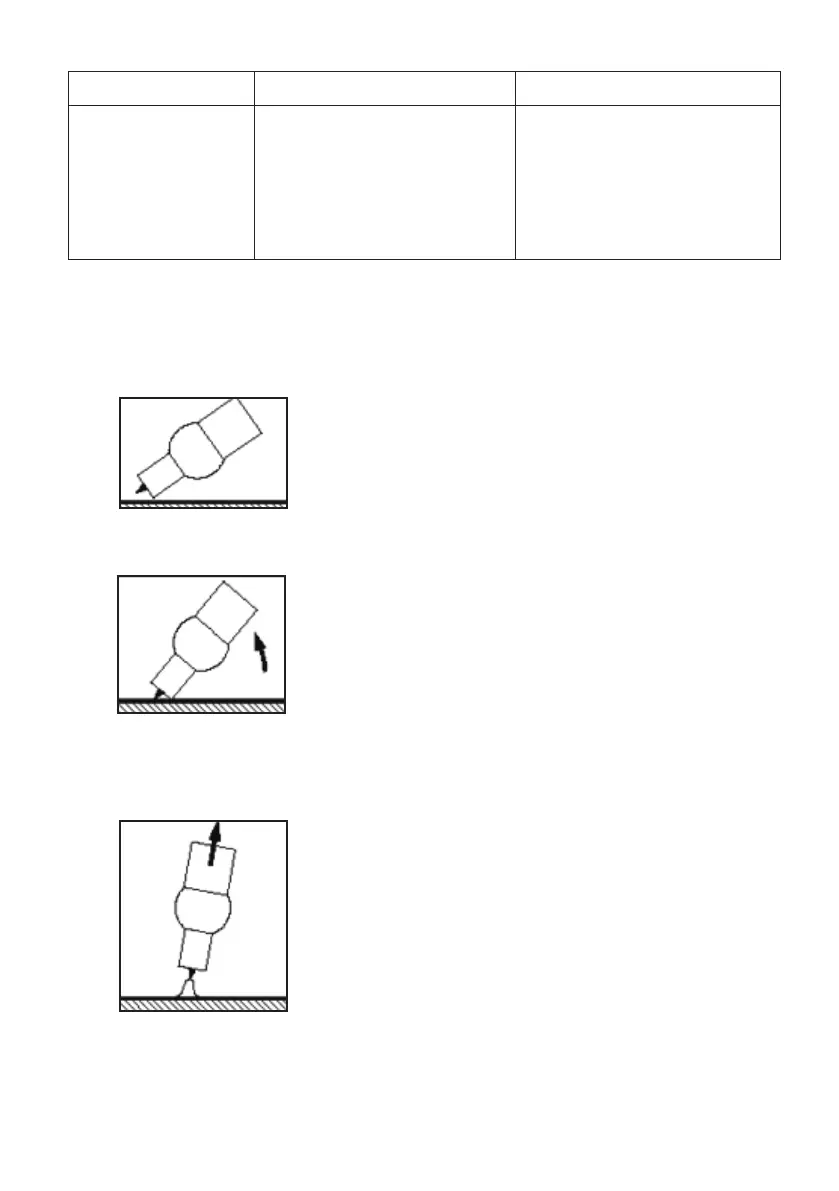

2. Tilt the torch at an angle, resting the alumina cup on the work piece,

3. Rotate the torch to a vertical position, as you do so the tungsten should make

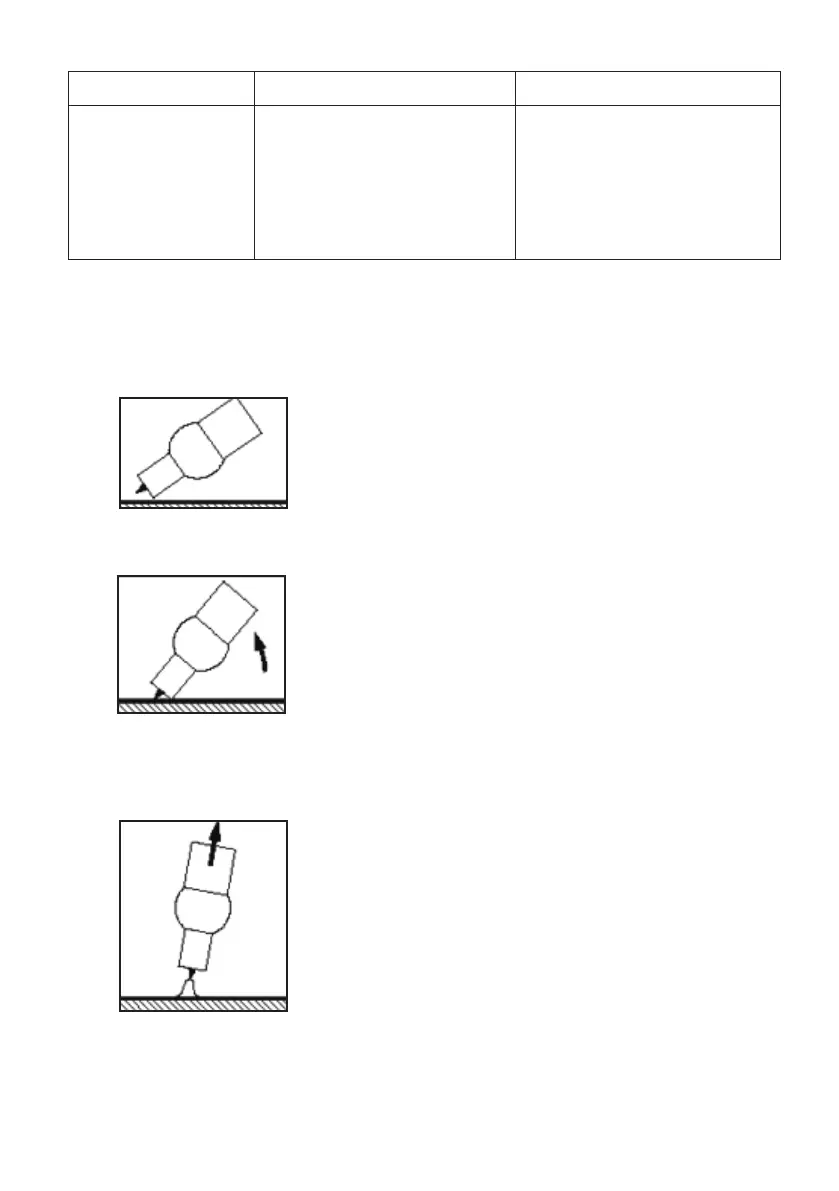

contact with the work piece and start the arc.

4. As soon as the arc is formed lift the torch from the work piece, by 2-3mm,

to prevent the tungsten from sticking to the work and contamination

of the tungsten.

Loading...

Loading...