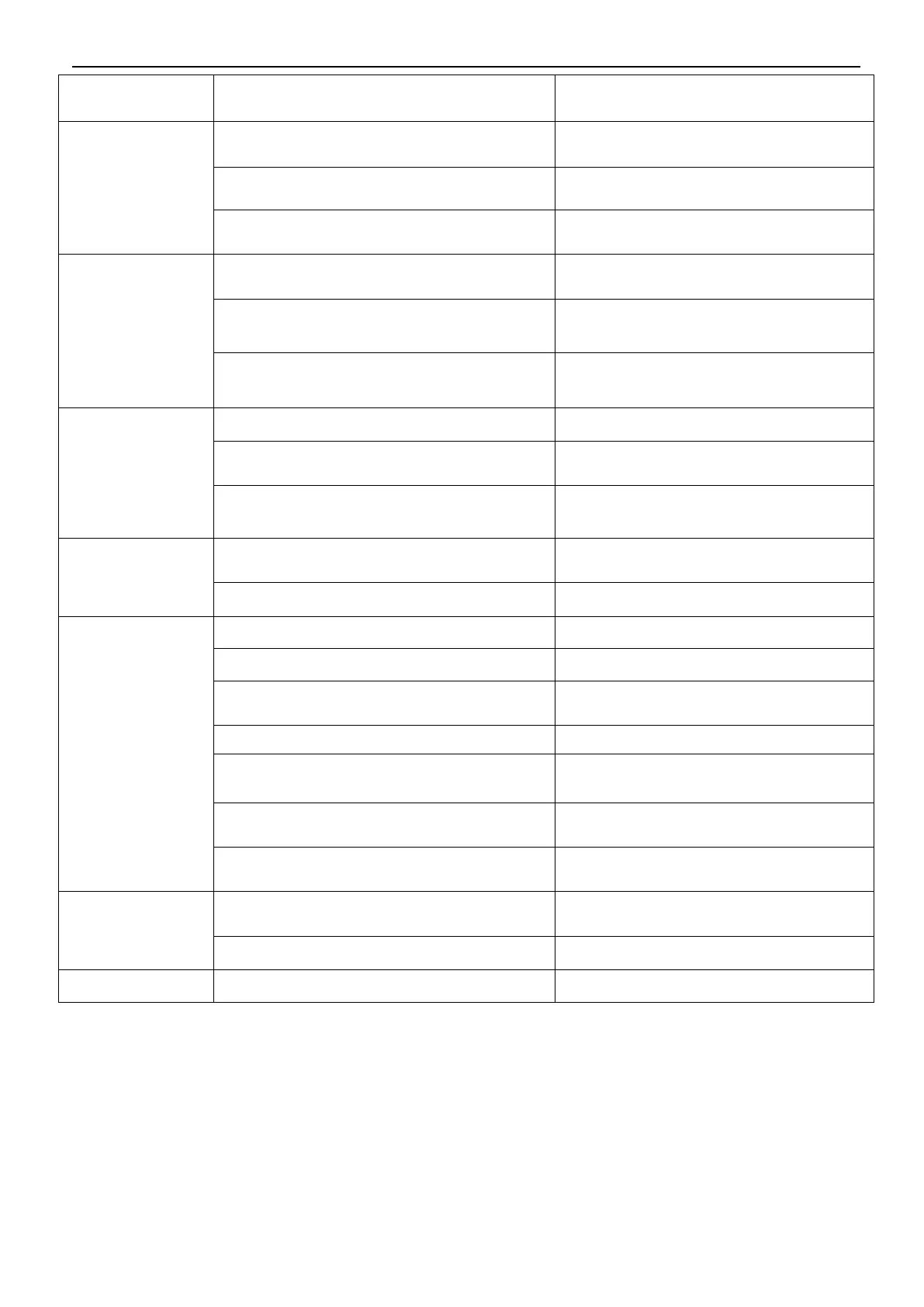

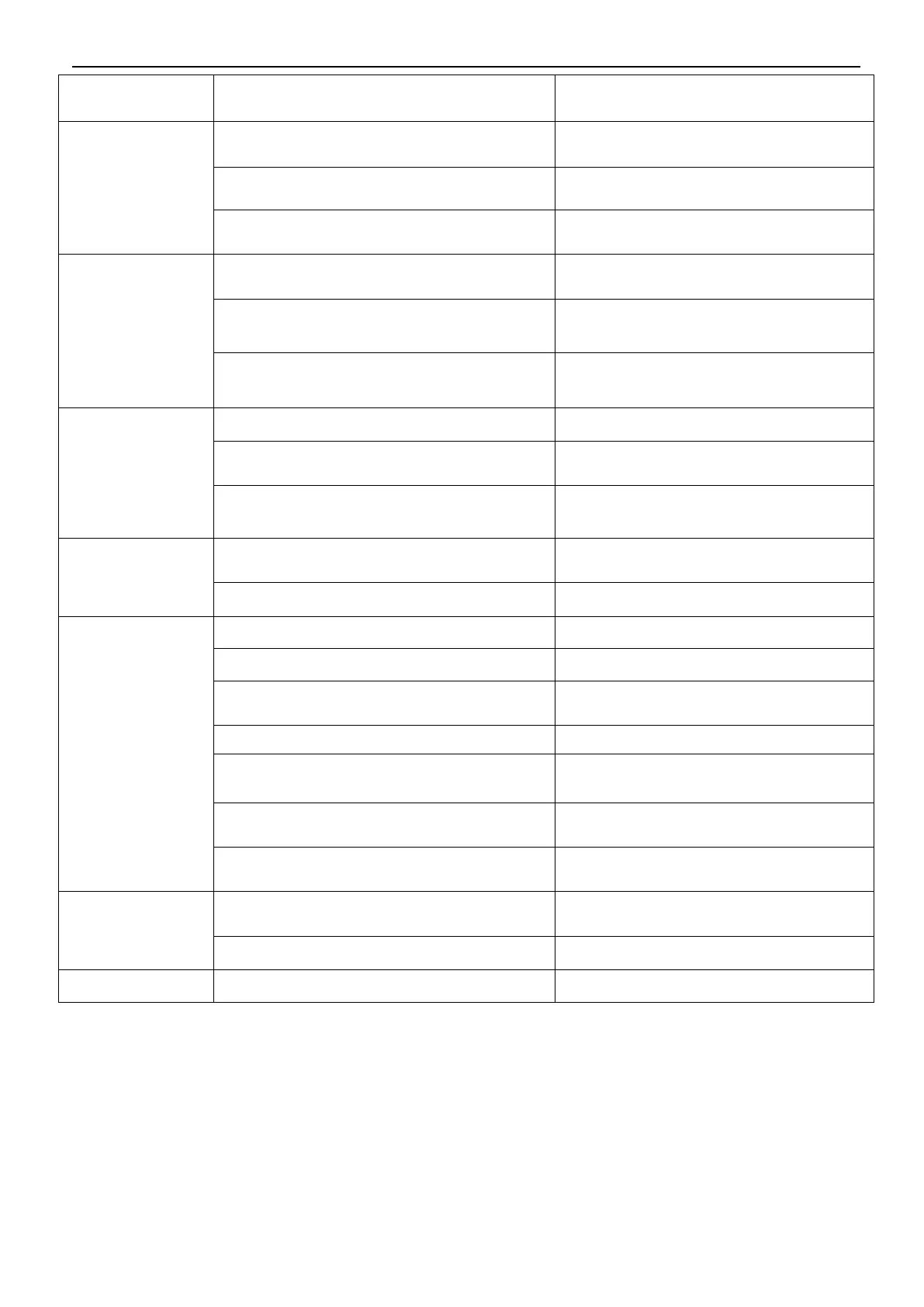

MCAC-ATSM-2014-09 R410a tropical air-cooled scroll chiller unit 60Hz

Troubleshooting 113

Compressor stops

because of motor

overload.

Over high air discharging pressure and air suction

pressure.

Clean the heat exchanger.

Check the EXV,capillary, filter.

High voltage or low voltage, signal phase or phase

unbalance.

Confirm voltage not higher or lower than the rated

voltage +/-10%.

Short circuit comes out from motor or

connecting interface.

Confirm resistors at motor are connected

corresponding to terminals.

Compressor stops

because of integrate

temp. sensor or air

discharge temp.

protection.

Over high or over low voltage.

Confirm voltage not higher or lower than the rated

voltage +/-10%.

Over high air discharging pressure or excessive low air

suction pressure.

Adjust refrigerant charge volume.

Clean the heat exchanger.

Check the EXV,capillary, filter.

Check the integrated temp. sensor after motor is

cool down.

Compressor stops

because of low pressure

Protection.

Filter of electronic expanding valve is blocked.

Low voltage switch error.

If the switch is defective, please replace a new

one.

Excessive low air suction pressure.

Add the refrigerant.

Clean the heat exchanger.

Check the EXV,capillary, filter.

Abnormal noise gives

out form compressor.

Liquid refrigerant flows into compressor from

evaporator result in liquid slugging.

Adjust refrigerant charge volume.

Replace a new compressor.

Over current relay trip up, fuse burnt out.

Replace damaged assembly.

Control circuit without power though.

Check the wring of control system.

High voltage or low voltage protection.

Reference to mention in above the parts of air

suction and discharge pressure error.

Coils inside contactor are burnt out.

Replace damaged assembly.

Wrong connection of phase sequence.

Re-connect and adjust the any 2 wires among 3

phases.

Water system error and flow volume controller short

connection.

Error signal delivered from wired controller.

Find out the error type and carry out the

corresponding measure to settle.

Air side heat exchanger

excessive frost.

4-way valve or thermal resistor error.

Check the running state. Replace a new one if

necessary.

Settle the short circuit of air discharge.

Fixing screws at panel are loosen.

Loading...

Loading...