Page17

8. Maintenance and test

8.1 Air leakage test

Tool: Air leakage device, soap water

1. Professional repair procedures

a) Connect product to the air leakage device and set the test pressure at 15kPa;

b) The plug valve shall be kept closed and the gas pipelines may be tested its leakage through air leakage

device;

c) All plug valves shall be kept open, block the injector at the burner, the flame-out protection valve is kept

open and the gas pipelines may be tested their leakage through air leakage device.

The leakage must be controlled below 0.5mL/min as required in the test.

2. Simple procedures:

a) Connect the product to the gas being used;

b) Smear soap water at each joint of the product gas pipelines, the plug valve is kept closed, check visually

each joint for air bubbles;

c) Smear soap water at each joint of product gas pipelines, all plug valves shall be kept open, the injector of

the burner shall be blocked, the flameout protection device valve shall be kept open and check visually

for any air bubbles;

No air bubbles shall be detected at each joint as required in the test.

Note: Any component of the product gas pipelines shall not be disassembled or replaced only if the air

leakage is proved in conformity with relevant requirements.

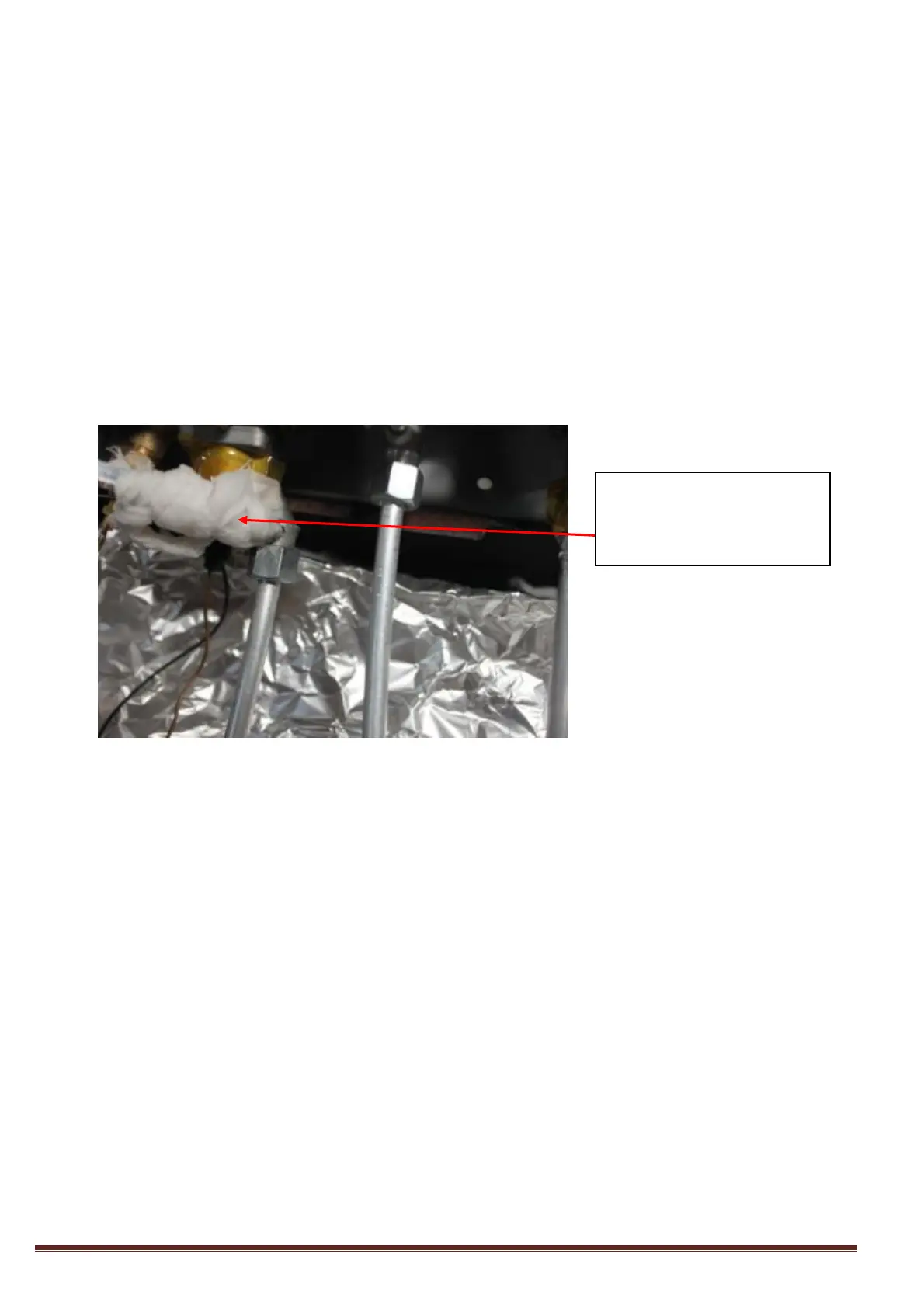

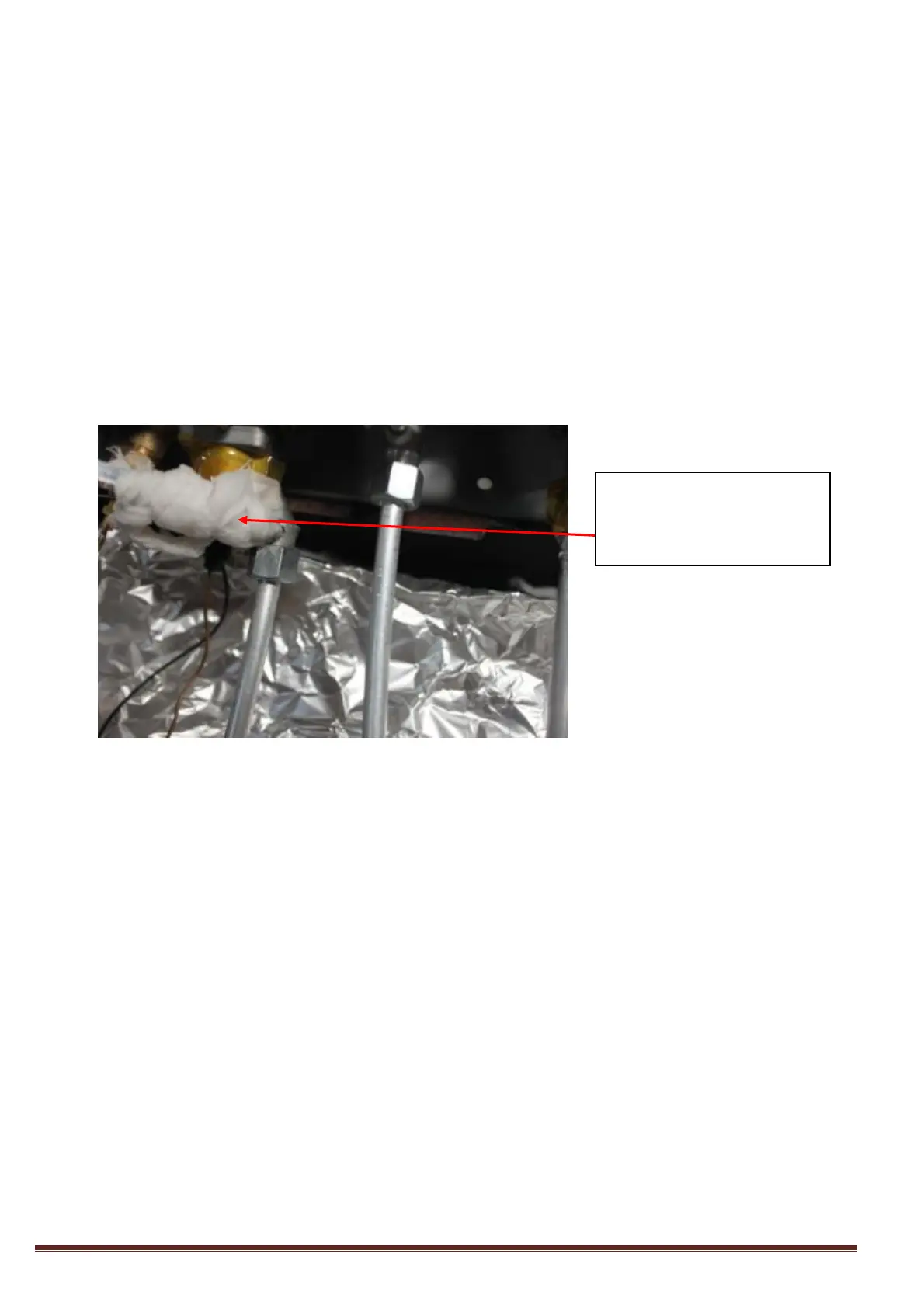

Smear with suds-immersed

fabric each joint of the gas

pipe lines and check visually

for any air bubbles.

Loading...

Loading...