12

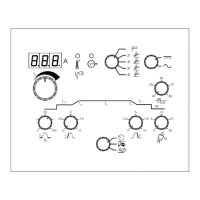

Connection and start-up

1. Mains connection

2. Power switch

3. Connection of shielding gas

4. Connection of welding hose

5. Welding hose

6. Connection of cooling hoses

7. Connection of cooling hoses

8. Connection of earth clamp (MIG) or electrode holder

9. Connection of push-pull welding hose (option)

10. Connection of earth clamp (MMA) or electrode holder

11. Cooling liquid level control

12. Refill of cooling liquid

13. Power switch for autotransformer (optional)

14. Activation of autotransformer in standby (optional)

Power

F

F

F

GAS

2-6 Bar

1

3

Max.5bar

2

4

8

13

14

2

4

5

8

Power

GAS

2-6 Bar

1

3

F

F

F

6 - 7

6 - 7

11

12

10

6 - 7

10

9

Adjustment of wire brake

The wire brake must ensure that the wire reel brakes

sufficiently before the welding wire runs over the

edge of the reel.

The brake force is dependent on the weight of the

wire reel and wire feed speed.

Factory setting is 15kg.

Adjustment:

• Dismount the

control knob by

placing a thin

screw driver behind

the knob and

thereafter pull it

out.

• Adjust the wire

brake by fastening

or loosening the self-locking nut on the axle of

the wire hub.

• Remount the control knob.

Connection of shielding gas

The shielding gas hose is fitted to the back panel

of the power source (3) and is connected to a gas

supply with a pressure reduction to 2-6 bar. One gas

cylinder can be mounted on the bottle carrier on the

back of a trolley if any.

Torch adjustment (Dialog torch)

The current size/wire feed speed can be adjusted

both from the machine and the welding torch if a

welding hose with dialog torch is in use. The torch

adjustment is passive without Dialog torch.

Inching

The function is used for wire

inching e.g. after change of

wire.

Gouging (only OMEGA

2

550)

1. Mount the carbon-arc torch

2. Mount the compressed air hose on the

compressor. Set the pressure between 5 and

7bar

3. Select MMA program. Set the machine at

max. current – not less than 400A

4. Select carbon electrode (6-8 mm)

5. Use protective equipment: ear protection,

welding goggles, gloves etc. Note! Metal sparks

pose fire danger.

Loading...

Loading...