13

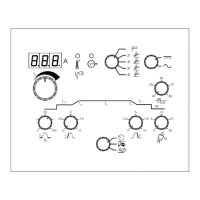

PI Plasma control panel

Panel LOCK

Keypads and encoder are disabled according to

selected mode 1 or 2.

When pressing locked key pads or rotating the encoder, the

display will flash “PA.L.” to remember the active protection.

0 = unlocked (default setting)

1 = locked, except “pilot arc ON/OFF”

2 = Completely locked

2-times option for torch trigger

Permit to define 2 different ways to control

the retrigger of machine during slope down. For detailed

description of different behaviours see the following

diagrams.

0: return to welding current by step (default)

1: return to welding current by slope up

4-times option for torch trigger

Permit to define 6 different ways to control the

torch trigger when the machine is set as 4Times stroke (Lift

or HF). For detailed description of different behaviours see

the following diagrams. Select a value in the range 0...5

(1=default setting)

Dynamic Oxide Control

0 = disabled

1 = enabled (default setting)

Remote Control Option

It is possible to select 4 different ways depending

from the external device connected to 8-pole plug

(option).

Welding current can be controlled up to previous SET or

to MAX. External reference voltage can be 0-10V or 0-5V

(Condition 2 & 3 presents lower resolution)

0 = 0-10V Imin to ISET (default)

1 = 0-10V Imin to IMAX

2 = 0-5V Imin to ISET

3 = 0-5V Imin to IMAX

Torch Remote Control

Makes it possible to control how the control unit

on the handle is used when torch adjustment is enabled.

0 = Setting the current reference (factory default).

1 = Enabling/disabling TIG-A-Tack (the TIG-A-Tack

button is disabled). The control unit is handled as

follows:

Steps 1-3: TIG-A-Tack is enabled

Steps 4-7: The trigger is disabled

Steps 8-10: TIG-A-Tack is disabled

2 = Up/Down module

* Keep pressed for constant increase/reduction

Saves all program settings in an SD card file. Insert an SD

card in the machine (same procedure as for SW update).

Loads program settings from SD card. Use P.SA. to save

program settings.

All the above settings will not be changed during reset to factory

settings.

1

Press / Release

By STEP

0

By SlopeUP

Press / Release

Press / Release

Press / Release

Press / Release

Press / Release

Stop when

slope completed

Keep

final current

0

1

2

3

Press / Release

Keep

final current

5

Press / Release

Stop when

slope completed

4

Stop when

key is released

Stop when

key is released

Stop when

slope completed

Stop when

key is released

Keep

start current

Keep

start current

Keep

start current

Stop when

key is released

Enabling/Disabling

TIG-A-Tack

Trigger

2A/* 2A/*

2A/* 2A/*

Trigger

Loading...

Loading...