9

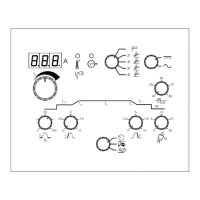

PI Plasma control panel

t 1 t 2

%

V

TIG PLASMA

GAS

L

/min

GAS GAS

/min

L

t

Control knob

All parameters are set by the use of only one

control knob. These parameters include current,

pulse time, slope-up time, etc.

This control knob is positioned in the right side of the

control panel. The digital display shows the value of

the parameter being set. The unit of measurement of

the parameter is shown on the right side of the digital

display.

A parameter can be selected by means of the relative

keypad in the relevant section. A bright indication light

indicates the parameter selected. The control knob is then

used for setting a new value.

Storage of parameters - programs

This function enables storage of programs

(often used machine settings) and shift from one

complete program to another. By pressing the keypad the

display shows a “P” and a number: “1”, “2” etc.

Each number includes a program with all parameters and

functions of the machine. It is therefore possible to have

one program for each welding job for which the machine

is used.

It is possible to store 64 settings in each welding process

(MMA, TIG and PLASMA) = 192 program settings.

Each program can be selected by:

1. Choose between MMA, TIG or PLASMA.

2. Select program number (P01…P64). The control knob

can be used for shifting between the programs when

the key pad is kept pressed down.

The latest used program setting in the relevant program

group (MMA, TIG and PLASMA) will be shown when the

program key pad is selected.

Reset of welding programs

Select the program that needs to be reset to factory

settings. Then keep the -key pad pressed for 5 seconds

without turning the encoder.

The program has been reset when the current program

number is flashing on and off in the display and the

-key pad can then be released again.

1

1

2

2 3

3

4

4

5

5

Welding current

The key pad can be used to display the welding

current. Adjustable from 5A to 350A in Plasma mode

and 5A to 500A in TIG/MMA mode. After the welding process

has stopped, the adjusted current is shown on the display.

During welding, however, the actual welding current is

shown. During pulse welding an average welding current is

automatically shown when shifting between welding current

and base current becomes faster than possible viewing.

Units for parameters

Units of measurement of the selected parameter.

Selection of welding process

Electrode welding (MMA)

Is used for selection of electrode welding. It is not

possible to change welding process during welding.

TIG welding

Press this knob to activate TIG process

PLASMA welding

Press this knob to activate TIG process

TIG and PLASMA welding

TIG and PLASMA welding

The parameters can be adjusted with the control

knob after they are shown on the display. Press the

relative key to select the parameter. The relevant LED will

illuminate.

Pre-flow [s]

Pre-flow is the period of time for which gas flows

after the torch switch is pressed and before the HF

arc is established. Variable 0-10 sec. In the LIFTIG process

the period is the time until the torch is lifted away from the

workpiece.

Start Amp [A%]

Immediately after the arc has been established,

the machine regulates the welding current to

the value stated in the Start Amp parameter. Start Amp is

set as a percentage of the required welding current and is

variable between 1-200% of the welding. Please note that

values higher than 100% generate a Start Amp bigger than

welding current.

6

6 7

7

8

t 1 t 2

Loading...

Loading...