10

Slope-up [s]

Once the arc has been established, the welding

process enters a slope-up stage during which the

welding current is increased in linear fashion from the

value stated in the Start Amp parameter to the required

welding current. The duration of this slope-up time is

variable 0-20 sec in steps of 0.1 sec.

Second current level (only TIG 4T stroke)

Adjustable from 10 to 200% of welding current.

It is activated in four-times only by pressing and releasing

quickly the torch trigger. Please note that values bigger

than 100% generate a secondary current bigger than

welding current.

Slope-down [s]

When welding has stopped by activating the

trigger, the machine enters a slope-down stage.

During this stage current is reduced from welding current

to Final Amp over a period of time called the slope-down

time and variable 0-20 sec in steps of 0.1 sec.

Final Amp [A%]

The slope-down stage is completed when the

current level has fallen to the value stated in

the Final Amp parameter. In TIG 4-times it is possible to

continue in Final Amp mode until the trigger is released,

depending from settings in user menu.

Final Amp is stated as a percentage of the required

welding current and is variable between 1-90% of the

welding current.

Spot time

The spot time in TIG is the time from the end of

slope up to beginning of slope down. Therefore, during

spot time the machine is welding with the adjusted

current. The LED flashes on and off when the function is

active.

Set the timer before igniting the arc. The torch trigger,

depending from the selected torch mode can interrupt

the spot welding time. Variable 0.01 - 600 secs.

The function is disconnected when the time is set to 0sec.

When used during tack welding, the timer can be set from

0.01 sec to 2.5 secs (See TIG-A-TACK).

Post-flow [s]

Post-flow is the period of time for which gas

flows after the arc is extinguished and is variable

0-20sec.

Synergic post-flow (option) can be activated in TIG DC by

adjusting time to less than 0 secs, if the IGC kit has been

mounted. The displays shows then IGC and the current

post-flow. The synergic post-flow can be adjusted +/- 50%

by pressing the -key pad and adjusting the control

knob (when the function is active).

11

IGC Gas control kit

Press on the -key pad until the gas pre-

flow and gas post-flow icons are turned

on. The gas flow is variable 4 - 26 l/min.

Synergic gas flow can be activated in TIG DC by setting

l/min to less than 4 l. The display shows then IGC and

the current gas flow level. The synergic gas flow can be

adjusted +/- 50% by pressing the -key pad and ajusting

the control knob (when the function is active).

The gas valve will be completely open and the gas

adjustment is disconnected when the gas flow rate is set

to 27l.

CWF wire program (option)

Press on the -key pad until the slope-

up and slope-down icons are turned on.

The display will show X.YY where X is the CWF unit and

YY is the relative program number to be used. Rotate

the encoder to select unit/program. 0.00 is used when NO

CWF must be activated. (default).

Pilot arc on/off (PLASMA welding)

Press the key pad for 6 seconds to turn ON the

pilot arc. Plasma gas will be opened immediately

to purge the torch system. Press again the key pad to turn

OFF the arc.

Pilot arc intensity (PLASMA welding)

Press the key pad to recall and regulate the

intensity of pilot arc. Amperage can be regulated

in the range of 3..20Amp in steps of 0.5Amps

Plasma gas flow (PLASMA welding)

Press the key pad to recall and regulate the

quantity of PLASMA GAS. Gas flow can be

regulated in the range of 0,1 .. 9,0 liters in steps of 0,1 l.

Plasma gas slope down (PLASMA welding)

The generator can produce a very precise gas

slope, synchronized with current slope down. It is

intended for “keyhole” applications.

Length of gas slope can be maximum the length of

current slope. Press the key pad to recall and regulate the

time for slope. Time can be regulated in steps of 0,1 sec.

Plasma gas final value (PLASMA welding)

This is the value of PLASMA gas reached at the

end of GAS slope down. It is kept until welding

procediment is stopped. It is intended for “keyhole”

applications. Press the key pad to recall and regulate the

value. It can be regulated in the range of 0,1 .. 9,0 liters in

steps of 0,1 l.

Slow pulse

Is used for selection of slow pulse.

The pulse current is equal to the set

current. It is possible to adjust:

Pulse time

Adjustable from 0.01 to 10 sec.

Pause time

Adjustable from 0.01 to 10 sec.

Base amp

Adjustable from 10 to 90% of the pulse current.

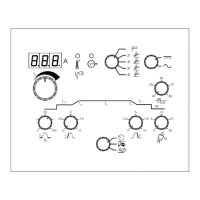

PI Plasma control panel

12

13

14

15

time

Amp

trig down ( ) / up ( )

slope-up

slope-down

spot

welding time

Loading...

Loading...