11

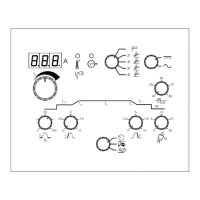

PI Plasma control panel

Fast pulse

Is used for selection of fast pulse.

The pulse current is equal to the set

current. It is possible to adjust:

Pulse frequency

For TIG DC/Plasma welding the range is 25-988 Hz

and for MMA DC welding the range is 25-100 Hz.

Base amp

Adjustable from 10 to 90% of the pulse current.

Synergy PLUS

TM

The machines automatically and dynamically adjust

all overall pulse parameters during welding, when

the peak welding current has been set by encoder.

TIG tack welding TIG-A-TACK

TM

The machine offers one tack welding function in

the individual program to allow quick switch-over

from welding to tack welding. In TIG DC and Plasma the

following features will be available:

- Arc ignition HF 2-times

- No slope-up/slope-down

- No pulse

- Reuse of pre-gas/post-gas values from the current

program

- Spot TIME from 0.01 to 2.5 secs in steps of 0.01 sec. Set

the value by selecting the parameter “spot time” .

Torch adjustment/remote control –

7-poled plug

The regulation of welding current is made by

means of the torch potentiometer (optional).

The maximum current reachable is the level previously

adjusted on the front panel. The minimum current is 5A.

External adjustment – 8-poled plug (optional)

Can be used for foot pedal (optional) and remote

control units (optional) that use a 8-poled plug.

The function is used for adjustment of the current.

The maximum current reachable is the level previously

adjusted on the front panel. The actual current is shown

on the display.

Ignition methods

It is possible to choose between 2 different

methods of ignition for TIG welding: High-

Frequency (HF) and LIFTIG ignition. The ignition method

cannot be changed during welding. The LIFTIG ignition

is active when the indicator is illuminated. The HF is

automatically active when the LED is switched off. A third

option permits the use of a TIG torch without trigger:

LIFTIG without TRIGGER.

HF-ignition (TIG and PLASMA welding)

In HF-TIG ignition the eletrode should not touch the

workpiece. A high-frequency (HF) impulse initiates the arc

when the torch trigger is activated.

The HF will not arise and the machine will stop if the

electrode is in contact with the workpiece. Detach the

electrode and start ignition again

LIFTIG-ignition (only TIG)

In LIFTIG ignition the TIG arc is ignited after making

contact between the workpiece and the tungsten

electrode, after which the trigger is activated and the arc

is established by lifting the electrode from the workpiece.

LIFTIG-ignition without Torch trigger (TIG)

This operation offers the possibility of using TIG torches without

trigger: turn ON the arc by touching the workpiece with the

electrode and lift the torch to ignite the arc. To activate the

operation keep pressed for 3 seconds the keypad “trigger

mode”: the relative led flashes on and off to indicate the new

function. Turn OFF the arc by removing the torch from the

workpiece.

Trigger mode

Selection of trigger mode. Four-times trigger mode is

active when the LED is illuminated, and two-times trigger

mode is active when the LED is turned off. It is not possible to

change trigger method during the welding process.

Two-times

The welding process begins by pressing the torch trigger.

Welding continues until the trigger is released again which

effects the slope-down period. It is possible to configure the

machine to work in 2 different ways when this mode is selected.

For detailed information read the section “USER MENU” conc.

“2t.o.”

Four-times (only TIG)

The welding process begins by pressing the torch trigger. If the

torch trigger is released during the slope-up period welding

continues with the adjusted welding current. In order to stop

the welding process the trigger must be pressed again for more

than 0.5s after which the slope-down period begins. The slope-

down period can be stopped by releasing the trigger. Thereafter

the post-flow starts. It is possible to configure the machine to

work in 3 different ways when this mode is selected. For detailed

information read the section “USER MENU” conc. “4t.o.”

Reset to factory settings of all programs

It is possible to recall all factory standard

parameters. In this case all programs in the

machine will be reset to the following value:

• MMA current 80A

• MMA hotstart 50%

• MMA arc power 50%

• TIG Current 80A

• TIG Spot Current 80A

• Plasma current 80A

• Plasma pilot arc 10A

• Plasma gas 3.0 liters

• Plasma gas slope down 0 sec.

• Plasma gas final value 0.1 liters

• Shield gas 3.0 liters

• Pre-flow 0.0 sec

• Post-flow 3.0 sec

• No slope-up/slope-down

• Start amp 40%

• Stop amp 20%

• Second Current level 50%

• Base amp 40%

• Fast pulse frequency 49Hz

• Pause time = Pulse time = 0.1 sec

• Cooling method = 1 (external cooling)

The reset procedure is as follows:

Switch off the machine and wait until display is extinguished.

Press the following key pads simultaneously:

Switch on the machine and keep the above keys

pressed until the display shows “X.XX”. Then release the keys.

X.XX is the software version of program.

23

24

25

26

27

28

29

Loading...

Loading...