11

TECHNICAL DATA

Power source PILOT 200 HP

Mains voltage 1x230V ±10%

50/60 Hz

Mains fuse Safety fuse 25 A

Automatic fuse 35 A

Efficiency 0.85

Current MMA DC 5 - 200 A

Current TIG AC/DC 5 - 200 A

Permitted load:

- at 100 % duty cycle 150 A

- at 60 % duty cycle 170 A

- at 30 % duty cycle 200 A

Open circuit voltage 92 V

TIG start HF / LIFTIG

Slope up 0.0 - 10 secs

Slope down 0.0 - 16 secs

Gas pre-flow 0.1 - 5.0 secs

Gas post-flow 3 - 25 secs

Initial current 0 – 100 % (50%)

Final current 0 – 100 % (0%)

Pulse frequency 0.2 - 99.9 Hz (20 Hz)

Pulse balance 20 – 80 % (20 %)

Hot start MMA (current +20 %) 0.0-5.0 secs (0 sec.)

1

Protection class IP 23

2

Application class

Standards EN/IEC60974-1

EN/IEC60974-10

Dimensions (W-H-L) 15x24x41 cm

Weight 7,7 kg

The numbers in brackets indicate the original

MIGATRONIC setting

1

The machine is designed for outdoor applications as it meets

the demands of protection class IP23. However, it is a

condition that the machine is placed in an upright position.

2

The machine meets the standards which are demanded of

machines working in areas where there is an increased risk

of electric shock

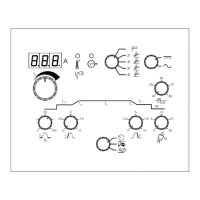

INITIAL INSTRUCTIONS

1

3

2

4

5

6

1. Setting of welding current and other parameters

2. Outlet for TIG torch

3. Outlet for welding current +pole

4. Setting of slope-down

5. Quick-release fitting for shielding gas outlet

6. Outlet for welding current ÷pole

7

8

9

7. Supply cable 1 x 230 V

8. Outlet for shielding gas

9. Main switch ON/OFF

Loading...

Loading...