Do you have a question about the Miller AlumaPower 450 MPa and is the answer not in the manual?

Discusses dangers related to arc welding, providing essential safety information to prevent injury.

Explains various symbols used for installation, operation, and maintenance safety to ensure proper understanding.

Details chemical warnings required by California law for welding equipment, concerning health risks.

Clarifies safety symbols specific to CE products, enhancing understanding of warnings and precautions.

Provides definitions for various symbols used throughout the manual for better comprehension and safe operation.

Highlights key features and benefits of the AlumaPower 450 MPa, explaining advanced technologies.

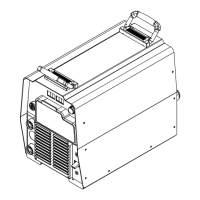

Lists technical specifications including input power, output, and ratings for proper setup and compatibility.

Explains duty cycle limits and overheating protection to ensure safe and optimal equipment operation.

Guides on choosing a suitable location for the welding unit, considering airflow and safety requirements.

Provides critical recommendations for electrical service requirements to prevent hazards and ensure correct setup.

Details the procedure for safely connecting the unit to the input power supply, adhering to safety standards.

Describes the functions of controls and indicators on the front panel for basic operation and parameter setting.

Explains how to access and use the configuration menu for customizing machine features and operation.

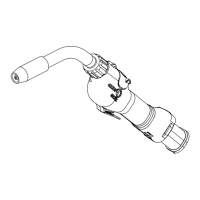

Illustrates the standard connection setup for remote control feeders in GMAW/GMAW-P processes.

Details how to operate the unit in MIG welding mode, including setup and parameter adjustments.

Explains the operation of the Pulsed MIG welding mode, including parameter adjustments for optimal results.

Outlines scheduled maintenance tasks to ensure the longevity and performance of the welding unit.

Provides instructions for safely accessing internal components and checking capacitor voltage before servicing.

Provides solutions for common problems and error displays to help diagnose and fix operational issues.

| Brand | Miller |

|---|---|

| Model | AlumaPower 450 MPa |

| Category | Welding System |

| Language | English |