What to do if cables and cords are cracked on Miller FieldPro Smart Feeder CE Welding System?

- CCorey HayesAug 3, 2025

Cracked cables and cords on your Miller Welding System should be repaired or replaced to ensure safe and efficient operation.

What to do if cables and cords are cracked on Miller FieldPro Smart Feeder CE Welding System?

Cracked cables and cords on your Miller Welding System should be repaired or replaced to ensure safe and efficient operation.

How to remove debris from internal mesh screen of Miller FieldPro Smart Feeder CE Welding System?

To remove debris from the internal mesh screen of your Miller Welding System, blow compressed air through the threaded male end of the fitting. This will dislodge any particles blocking the screen.

Why replace damaged or unreadable labels on Miller Welding System?

Replace any damaged or unreadable labels on your Miller Welding System to ensure clear identification of components and safety information.

Explains manual symbols and warns about electric shock hazards.

Details risks from fumes, gases, arc rays, fire, explosion, noise, and cylinders.

Covers HF/arc interference, extra symbols, Prop 65, standards, and EMF.

Explains additional safety symbols used on CE products.

Defines various symbols related to operation and specifications.

Location of serial number and rating label for input requirements.

Technical details including power, speed, wire diameter, and dimensions.

Lists recommended guns for different welding processes.

Details IP rating, EMC, hazardous substances, and temperature.

Guidelines for choosing a suitable installation location with airflow.

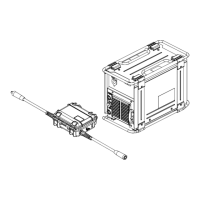

Illustrates connections for power source, feeder, gun, and gas.

Explains Weld Cable Control applications with specific power sources.

Steps for connecting the feeder to the PipeWorx 350 power source.

Step-by-step guide for setting up the feeder and power source.

Instructions for installing and aligning wire drive components.

Details on how to connect the welding gun to the wire feeder.

Describes rear panel connections and optional gas flow meter.

Guide for choosing appropriate weld cable sizes based on length and amperage.

Step-by-step instructions for installing and threading welding wire.

Identifies and explains the function of front panel controls.

Describes the setup panel and its components for configuring the feeder.

Provides recommended parameters for RMD and Pulse-MIG processes.

Instructions for restoring defaults and viewing software versions.

Guide to adjusting preflow and postflow times for wire feeder outputs.

Outlines a schedule for regular maintenance tasks.

Steps for cleaning debris from the gas filter fitting.

Lists common problems and their remedies for the wire feeder.

Explains display codes, their faults, and descriptions.

Diagram showing the overall assembly of the smart feeder.

Exploded view of the lower chassis components.

Exploded view of the center assembly components.

Exploded view of the user interface external components.

Exploded view of the optional gas flow meter kit.

Table listing drive rolls and inlet guides by wire diameter.

| Brand | Miller |

|---|---|

| Model | FieldPro Smart Feeder CE |

| Category | Welding System |

| Language | English |